Why is the harmonic drive motor the best choice for exoskeleton robots?

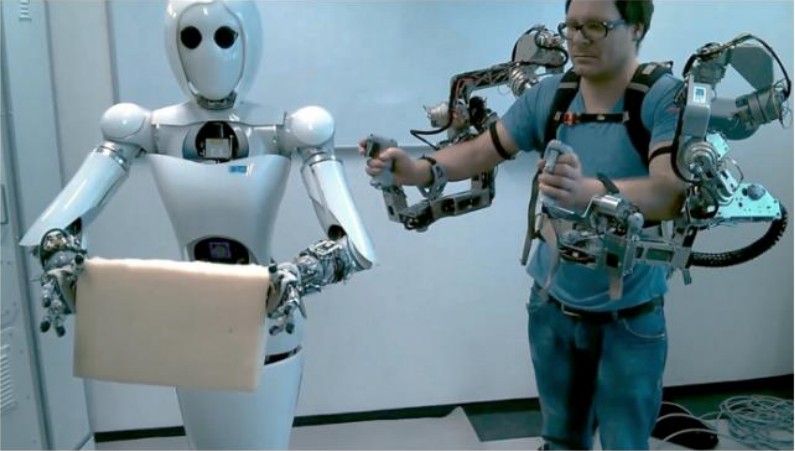

What is an exoskeleton robot?

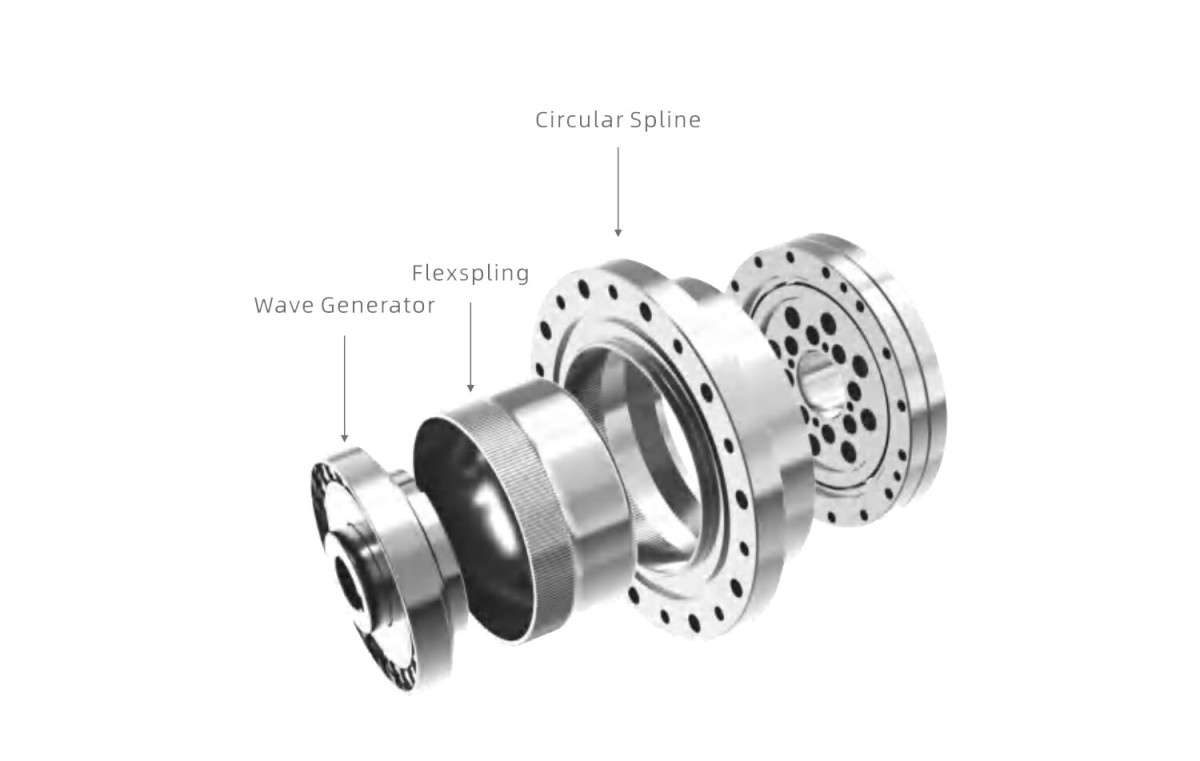

Exoskeletons typically incorporate harmonic drive motors, sensors, and other components that integrate sensing, control, information processing, data fusion, and mobile computing technologies. These systems synchronize human sensory and motor functions with robotic power transmission and control systems, serving to enhance physical capabilities or provide medical rehabilitation. As a cutting-edge disruptive technology, exoskeletons hold significant strategic importance for both military and medical applications. The high torque density and precision control offered by harmonic drive reducers make them the preferred solution for exoskeleton robots.

Why do exoskeleton robots need harmonic drive reducers?

Exoskeleton robots represent a category of wearable robotics. Given the close physical interaction between user and exoskeleton, these devices must feature ergonomic designs, lightweight construction, and the ability to move synchronously with the wearer without causing motion restriction or resistance. Harmonic drive reducers meet exoskeleton transmission requirements through their:

High torque output

Exceptional precision

Compact form factor

Low operational noise

Zero backlash

Impact resistance

These characteristics make harmonic drive reducers the optimal choice for high-performance exoskeleton designs.

Classification of exoskeleton robots

Exoskeleton robots are primarily categorized into:

Medical rehabilitation exoskeletons

Industrial augmentation exoskeletons

Military powered exosuits

Flexible wearable devices

Each type has distinct requirements for harmonic drive reducers.

Harmonic drive reducer applications in exoskeletons

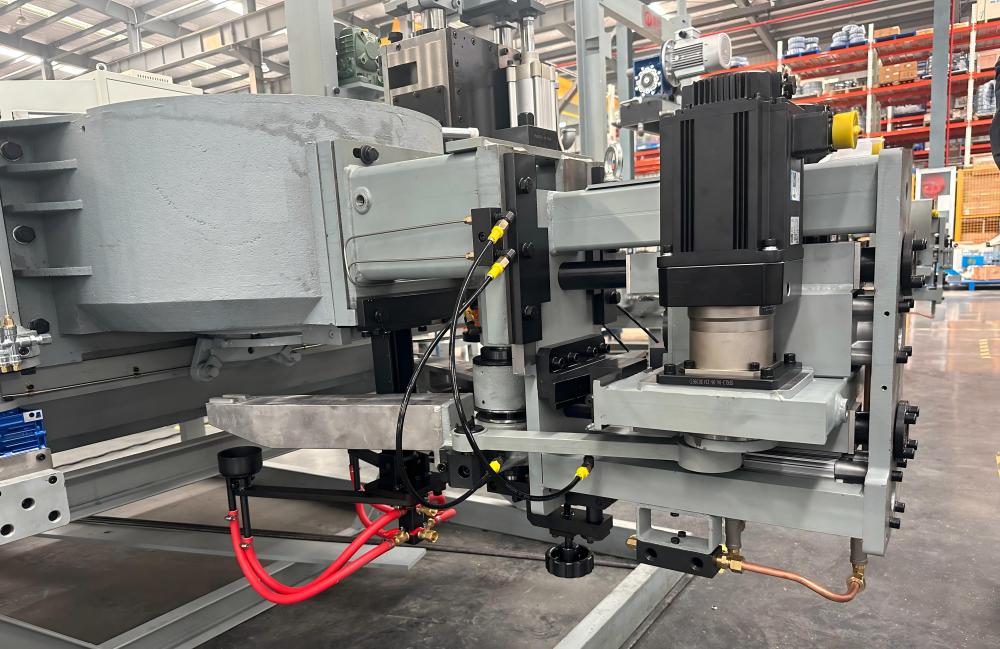

HONPINE provides customized solutions through all development stages, from prototyping to testing. Representative applications include:

1,Lower limb exoskeletons

Knee joint actuation: Harmonic drive reducers pair with brushless motors to convert high-speed/low-torque input to low-speed/high-torque output for walking and stair-climbing assistance.

2,Upper limb exoskeletons

Shoulder/elbow joints: HONPINE's SHD series lightweight reducers minimize muscle strain during industrial lifting operations.

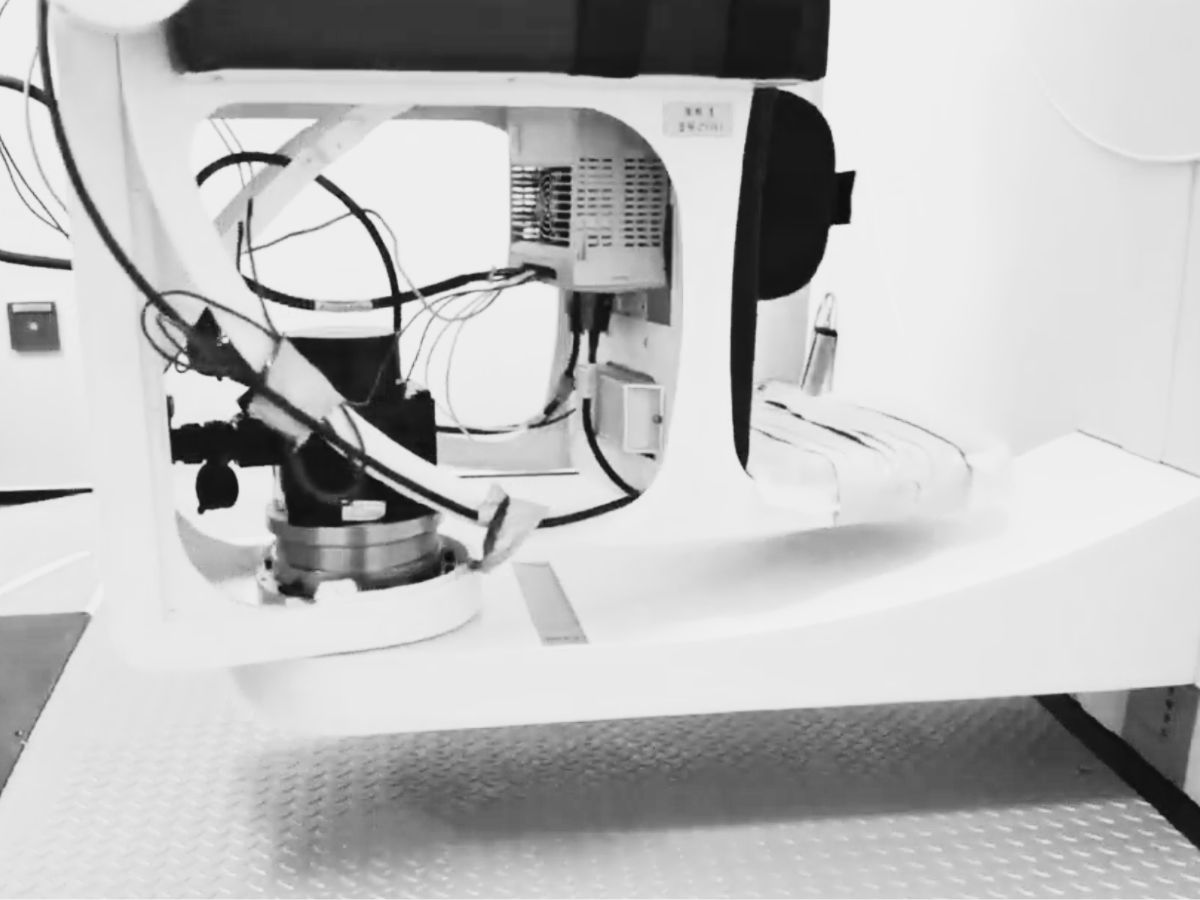

3,Flexible wearable systems

Integrated designs combining harmonic drive reducers with series elastic actuators (SEAs) enable compliant motion control (e.g., Harvard's soft exoskeleton).

Future development trends

Mechatronic joint modules will reduce R&D costs through standardization

Chinese manufacturers like HONPINE are emerging as market leaders by offering:

Superior cost-performance ratios

Shorter lead times

Japanese-comparable quality standards

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand