Harmonic Planetary Frameless Robot Joint Motor

Harmonic Joint Motor

HONPINE harmonic drive joint motors are characterized by high precision, high torque, and large hollow core diameter, often providing solutions for applications in confined spaces. Customization is supported, and these motors are frequently used in the field of specialized robotics.

![Human Robot Harmonic Joint Module with Torque Sensor and Integrated Cable Connector Human Robot Harmonic Joint Module with Torque Sensor and Integrated Cable Connector]() Human Robot Harmonic Joint Module with Torque Sensor and Integrated Cable ConnectorThe TCHL Harmonic Joint Module is a harmonic joint module that integrates a torque sensor directly into the harmonic drive reducer. The torque sensor enables precise measurement of the drive system’s operating status and required torque values, allowing accurate load detection of the actuator. This helps prevent overload and enables safer human–robot interaction.

Human Robot Harmonic Joint Module with Torque Sensor and Integrated Cable ConnectorThe TCHL Harmonic Joint Module is a harmonic joint module that integrates a torque sensor directly into the harmonic drive reducer. The torque sensor enables precise measurement of the drive system’s operating status and required torque values, allowing accurate load detection of the actuator. This helps prevent overload and enables safer human–robot interaction.

The module features fully integrated cables and connectors, allowing fast, precise component connections and enabling safe, responsive motion control through a highly integrated design.Details![Cobots Robot Arm T type Harmonic Rotary Joint Module Cobots Robot Arm T type Harmonic Rotary Joint Module]() Cobots Robot Arm T type Harmonic Rotary Joint ModuleThe T-type harmonic joint module is a highly integrated robotic joint unit that combines a harmonic reducer, torque motor, precision sensors, brake, and driver. It is called “T-type” because the output flange is perpendicular to the motor shaft, forming a T-shaped layout ideal for rotary robot joints.

Cobots Robot Arm T type Harmonic Rotary Joint ModuleThe T-type harmonic joint module is a highly integrated robotic joint unit that combines a harmonic reducer, torque motor, precision sensors, brake, and driver. It is called “T-type” because the output flange is perpendicular to the motor shaft, forming a T-shaped layout ideal for rotary robot joints.

Designed for collaborative robots, the module simplifies development by integrating key components into one compact, plug-and-play unit. This greatly shortens the development cycle, lowers costs, and makes building a robotic arm almost as easy as assembling LEGO blocks. Its high integration also improves maintenance efficiency and expands the applicability of robotic-arm technology.Details![Sealing Design Robot Joint Module for Underwater Operation Special Robot Sealing Design Robot Joint Module for Underwater Operation Special Robot]() Sealing Design Robot Joint Module for Underwater Operation Special RobotThe joint module achieves highly optimized volume and weight through fully integrated components including harmonic reducer, frameless torque motor, brake, encoder and driver, enabling precise motion control with greater torque output, higher accuracy, more compact size and lighter weight. We also provide customized solutions to meet specific requirements for personalized applications and special operating environments, with the most common customizations being waterproof versions (resistant to water splashes, sprays or underwater operation up to 1 meter depth) and low-temperature adaptations. This waterproof joint module is specifically designed for special robots operating underwater, developed as an enhanced version of our standard joint module with dedicated improvements to address waterproofing challenges in robotic joints.Details

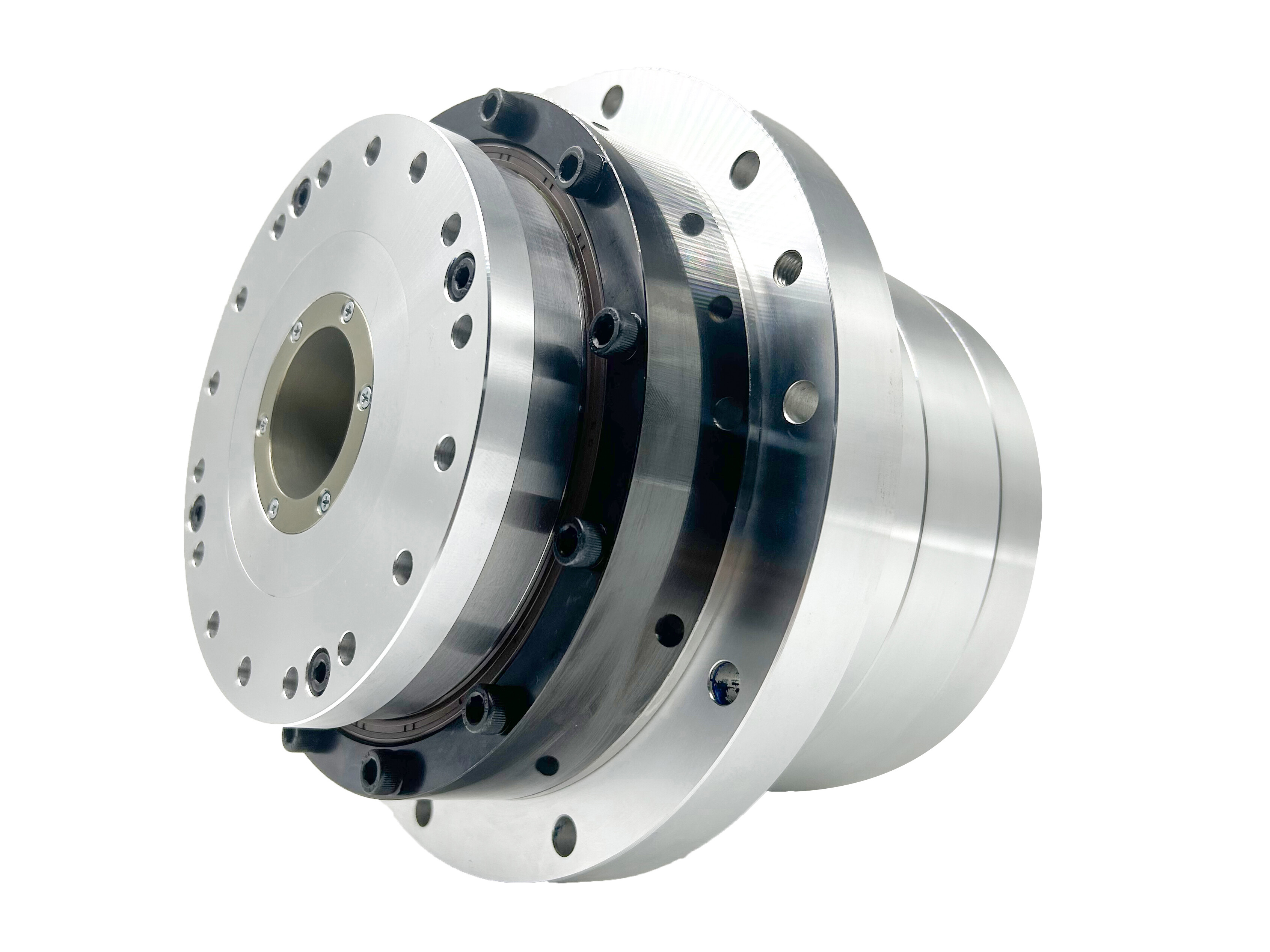

Sealing Design Robot Joint Module for Underwater Operation Special RobotThe joint module achieves highly optimized volume and weight through fully integrated components including harmonic reducer, frameless torque motor, brake, encoder and driver, enabling precise motion control with greater torque output, higher accuracy, more compact size and lighter weight. We also provide customized solutions to meet specific requirements for personalized applications and special operating environments, with the most common customizations being waterproof versions (resistant to water splashes, sprays or underwater operation up to 1 meter depth) and low-temperature adaptations. This waterproof joint module is specifically designed for special robots operating underwater, developed as an enhanced version of our standard joint module with dedicated improvements to address waterproofing challenges in robotic joints.Details![Large Hollow Bore Harmonic Drive Rotary Actuator Large Hollow Bore Harmonic Drive Rotary Actuator]() Large Hollow Bore Harmonic Drive Rotary ActuatorThe large hollow bore rotary actuator typically integrates an internal rotor frameless torque motor with components such as a harmonic drive reducer, absolute encoder, and customized large hollow bore harmonic drive unit to form a complete rotary actuator assembly. Its control unit (drive system) is usually externally mounted, enabling high-precision motion control for connected equipment. Compared to standard rotary actuators, this series features a larger hollow bore diameter, allowing passage of lead screws, cables, and other components. It is designed for applications requiring large through-bore space, high precision, and compact integration, such as machine tool rotary tables, precision medical devices, 5-axis laser cutting systems, and semiconductor equipment.Details

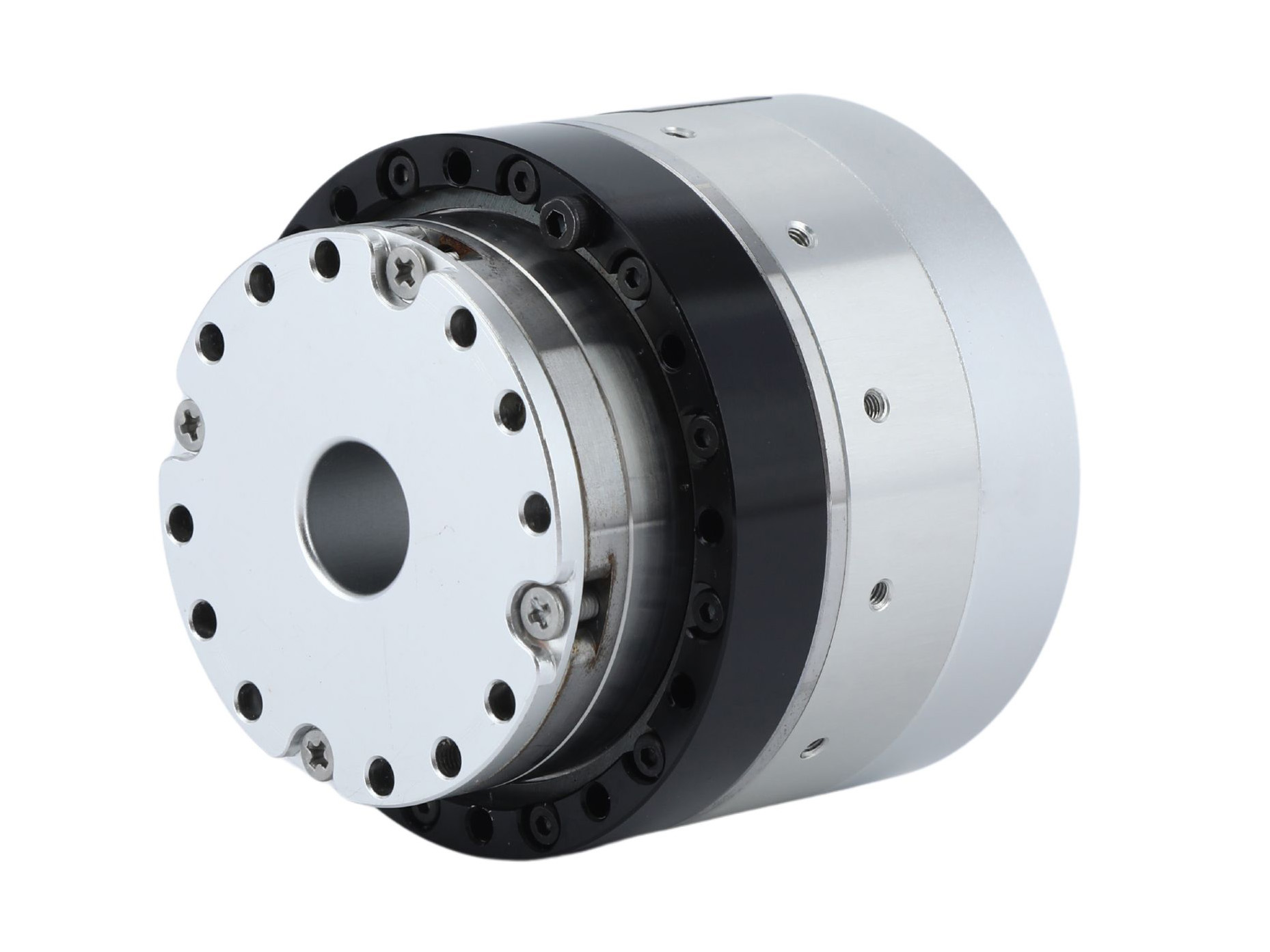

Large Hollow Bore Harmonic Drive Rotary ActuatorThe large hollow bore rotary actuator typically integrates an internal rotor frameless torque motor with components such as a harmonic drive reducer, absolute encoder, and customized large hollow bore harmonic drive unit to form a complete rotary actuator assembly. Its control unit (drive system) is usually externally mounted, enabling high-precision motion control for connected equipment. Compared to standard rotary actuators, this series features a larger hollow bore diameter, allowing passage of lead screws, cables, and other components. It is designed for applications requiring large through-bore space, high precision, and compact integration, such as machine tool rotary tables, precision medical devices, 5-axis laser cutting systems, and semiconductor equipment.Details![Highly Integrated Compact Harmonic Drive Robot Joint Motor Highly Integrated Compact Harmonic Drive Robot Joint Motor]() Highly Integrated Compact Harmonic Drive Robot Joint MotorThe Robot Joint Motor achieves highly precise motion control through integrated components including harmonic drive, frameless torque motor, brake, encoder, and drive unit, with optimized size and weight. It delivers greater torque, higher precision, more compact size and lighter weight. We also provide customization services according to customers' specific requirements.

Highly Integrated Compact Harmonic Drive Robot Joint MotorThe Robot Joint Motor achieves highly precise motion control through integrated components including harmonic drive, frameless torque motor, brake, encoder, and drive unit, with optimized size and weight. It delivers greater torque, higher precision, more compact size and lighter weight. We also provide customization services according to customers' specific requirements.

Robot Joint Motors typically support a wide voltage range of DC24V~DC48V. As a core component in robotics industry, the technological advancement of Robot Joint Motors will continue to promote the development of specialized robots and humanoid robots towards higher flexibility and broader application scenarios. Beyond robotics, Robot Joint Motors are also applied in semiconductor equipment, photovoltaic equipment, precision medical equipment, 3C equipment, optical equipment and other fields.Details

Planetary Joint Motor

The planetary joint motor is also a core component of robotic power systems. Compared to harmonic joint modules, it features a smaller reduction ratio, higher output speed, and greater rigidity, though with slightly lower overall output accuracy. Through highly integrated components including planetary reducers, frameless torque motors, brakes, encoders, and drivers, its size and weight are significantly optimized, enabling precise joint motion control. This results in higher torque, more compact dimensions, and lighter weight. Planetary joint motors typically support a wide voltage range, adapting to low-voltage DC 24V~48V. We also offer customized solutions based on individual customer requirements.

Frameless Torque Motor

The frameless torque motor, a specialized type of permanent magnet synchronous motor (PMSM), consists of two core components: the rotor and stator, while eliminating traditional motor structures such as housings, bearings, and shafts. Designed for direct integration into a customer’s mechanical system, it requires the end-user to supply supporting bearings and enclosures. This design philosophy delivers higher flexibility, more compact dimensions, and superior performance, making it ideal for applications with stringent demands on space, weight, and dynamic capabilities. It excels in high-precision, high-dynamic-response scenarios, including humanoid robot joint actuation, precision rotary stages, medical equipment, and industrial automation systems.Frameless torque motors are further subcategorized into internal rotor frameless motors and external rotor frameless motors, depending on their structural configuration.

![FMK Highly Integrated Robot Joint Frameless Torque Motors FMK Highly Integrated Robot Joint Frameless Torque Motors]() FMK Highly Integrated Robot Joint Frameless Torque MotorsFrameless torque motors, unlike traditional servo motors, consist only of stator and rotor components. Compared to framed motors, frameless motors offer flexible configuration and easy installation. Considering the increasing trend of highly integrated drive systems, frameless motors better meet the expectations of engineers. Engineers no longer need to consider motor interfaces in system design, allowing for maximum reduction of space occupied by the power output unit in the drive system, leading to higher system integration.The HONPINE FMK frameless torque motors are now widely used in the J1–J6 joints of collaborative and dual-arm robots, the walking joints of quadruped robots, and the flexible joints of humanoid robots.Details

FMK Highly Integrated Robot Joint Frameless Torque MotorsFrameless torque motors, unlike traditional servo motors, consist only of stator and rotor components. Compared to framed motors, frameless motors offer flexible configuration and easy installation. Considering the increasing trend of highly integrated drive systems, frameless motors better meet the expectations of engineers. Engineers no longer need to consider motor interfaces in system design, allowing for maximum reduction of space occupied by the power output unit in the drive system, leading to higher system integration.The HONPINE FMK frameless torque motors are now widely used in the J1–J6 joints of collaborative and dual-arm robots, the walking joints of quadruped robots, and the flexible joints of humanoid robots.Details![Dynamic Response High Torque Density External Rotor Frameless Torque Motor Dynamic Response High Torque Density External Rotor Frameless Torque Motor]() Dynamic Response High Torque Density External Rotor Frameless Torque MotorThe external rotor frameless torque motor is a specialized type of permanent magnet synchronous motor (PMSM) composed of two core components: the rotor and stator. Unlike traditional internal rotor designs, this motor features an externally mounted rotor and an internally positioned stator. The innovative design eliminates traditional motor housings, bearings, and shafts, retaining only the rotor and stator assemblies. The rotor, located outside the stator, integrates permanent magnets with the outer shell and is directly embedded into the load structure. The stator, positioned internally, contains copper windings and laminations, driving the external rotor’s rotation via electromagnetic forces. This design combines the high moment of inertia of the external rotor configuration with the compactness of the frameless structure, making it ideal for applications requiring low-speed high-torque output and efficient heat dissipation, such as medical equipment, industrial fans, and automated industrial systems.Details

Dynamic Response High Torque Density External Rotor Frameless Torque MotorThe external rotor frameless torque motor is a specialized type of permanent magnet synchronous motor (PMSM) composed of two core components: the rotor and stator. Unlike traditional internal rotor designs, this motor features an externally mounted rotor and an internally positioned stator. The innovative design eliminates traditional motor housings, bearings, and shafts, retaining only the rotor and stator assemblies. The rotor, located outside the stator, integrates permanent magnets with the outer shell and is directly embedded into the load structure. The stator, positioned internally, contains copper windings and laminations, driving the external rotor’s rotation via electromagnetic forces. This design combines the high moment of inertia of the external rotor configuration with the compactness of the frameless structure, making it ideal for applications requiring low-speed high-torque output and efficient heat dissipation, such as medical equipment, industrial fans, and automated industrial systems.Details![Compact Lightweight High Power Density Internal Rotor Frameless Torque Motor Compact Lightweight High Power Density Internal Rotor Frameless Torque Motor]() Compact Lightweight High Power Density Internal Rotor Frameless Torque MotorThe internal rotor frameless torque motor is a specialized type of permanent magnet synchronous motor (PMSM) composed of two core components: the rotor and stator. The rotor is internally positioned, while the stator is externally mounted. Its innovative design eliminates traditional motor housings, bearings, and shafts, retaining only the rotor and stator assemblies. The rotor typically adopts a ring-shaped structure integrated with permanent magnets, directly mounted on the load shaft. The stator consists of copper windings and laminations, generating electromagnetic forces to drive rotor rotation. This configuration achieves torque output through efficient magnetic field interaction, making it ideal for high-precision applications such as robotic joints and industrial automation. It enables direct load driving, minimizing mechanical transmission losses.Details

Compact Lightweight High Power Density Internal Rotor Frameless Torque MotorThe internal rotor frameless torque motor is a specialized type of permanent magnet synchronous motor (PMSM) composed of two core components: the rotor and stator. The rotor is internally positioned, while the stator is externally mounted. Its innovative design eliminates traditional motor housings, bearings, and shafts, retaining only the rotor and stator assemblies. The rotor typically adopts a ring-shaped structure integrated with permanent magnets, directly mounted on the load shaft. The stator consists of copper windings and laminations, generating electromagnetic forces to drive rotor rotation. This configuration achieves torque output through efficient magnetic field interaction, making it ideal for high-precision applications such as robotic joints and industrial automation. It enables direct load driving, minimizing mechanical transmission losses.Details

Our harmonic drive modules feature a high-precision 16-bit encoder resolution, providing 65,536 discrete positions per revolution. This means the full 360° rotation is divided into extremely fine increments for exceptional positional accuracy at the motor end.

With the continuous expansion of large-scale manufacturing capabilities and ongoing technological innovation, HONPINE aims not only to deliver products that are reliable, mass-producible, and cost-effective, but also to accelerate the industrialization of humanoid robots and embodied intelligence robots.

HONPINE harmonic joint motors feature:

High torque output

High precision

High reduction ratio

Compact structure

Low noise

Low vibration

They are especially suitable for robot arm joints, where extremely high requirements for accuracy, force control, and lightweight design are critical.

The hollow shaft design allows cables, pneumatic lines, or signal wires to pass through the center, reducing joint diameter and making cable routing simpler and more reliable. This significantly lowers wiring complexity and improves overall system integration in robotic applications.

A harmonic joint module supports rotational motion of robot joints and achieves a repeat positioning accuracy of up to ±0.001°.

It delivers high torque density (>100 N·m/kg) within a compact space, making it ideal for applications such as:

Humanoid robot joints

Welding and handling robots

Medical machinery

Industrial automation equipment

Electric drive systems

Service robots and other robotic systems

A harmonic joint module achieves precise position and torque control for robot joints through the high reduction ratio (typically 50–160:1) and low backlash (less than 1 arcmin) of the harmonic reducer.

In addition, the module integrates encoders and torque sensors, enabling real-time torque adjustment with an accuracy of ±0.1 N·m, making it well suited for flexible and compliant assembly tasks.

Essentially, one main controller can handle four modules. While the normal communication cycle is 0.5ms per transmission, it does not consistently maintain this interval—for instance, high-frequency sampling is unnecessary during alarm states or similar conditions.

Based on the CAN protocol, a single motor requires 0.5ms for each transmission and reception. For multiple motors, this time accumulates accordingly.

Yes. It employs a multi-turn absolute encoder. However, due to a reduction gear at the output, an encoder battery is required to retain the multi-turn position count. Customization is supported, allowing the option to have the motor with or without the encoder battery.

The HONPINE joint motor uses a magnetic encoder with a resolution of 65,536 units per revolution.

Complete mechanical specifications including mass and volume for all module variants are available in our Model Selection Brochure. Download the brochure from our resources section or contact our sales team for specific dimensional requirements.

Due to the highly compact design of our integrated driver system, HONPINE current robot joint modules don't include general-purpose I/O pins. This streamlined design allows for optimal space savings in robotic applications.

While HONPINE standard robot joint modules don't include integrated torque measurement, we can accommodate torque sensing requirements by integrating an external torque sensor. Please contact our technical team for customized solutions.

HONPINE harmonic drive modules utilize a different safety approach. Instead of STO, we incorporate a reliable built-in electromagnetic brake system that automatically engages to stop rotation immediately when power is disconnected, ensuring safe operation.

Core Parameters

16-bit resolution: 65,536 pulses per motor revolution.

Gear ratio: e.g., 101:1 means the output turns once for every 101 motor turns.

Output Speed

Output speed = motor speed ÷ gear ratio.

Example: motor at 1 rev/sec (65,536 pulse/sec) with a 101:1 ratio → output completes 1 revolution in 101 seconds.

Unit Conversion

Rad/s conversions:

1 rad/s ≈ 57.3 °/s

1 rad/s ≈ 9.55 rpm

Pulse/s ↔ rpm (16-bit encoder):

1 rpm ≈ 1092.27 pulse/s

1 pulse/s ≈ 1/1092.27 rpm

Note: Calculations are based on physical relationships. For example, 1 rad/s = 60/(2π) rpm.

Planetary Joint Motor - FAQ

To meet the stringent precision requirements of industrial manufacturing, the module adopts a helical planetary gear reduction structure. Through optimized tooth surface design, the gear backlash is controlled within 10 arcminutes (approximately 0.167°), achieving a repeat positioning accuracy of ±12 arcminutes.

Combined with a 3 kHz high-frequency control signal and a response time of ≤200 μs, the system avoids product loss caused by delay or positioning errors, even in micron-level operations such as precision electronic component assembly and lithium battery tab welding.

For heavy-load applications, the module uses military-grade reinforced gear materials and bearing structures. The peak torque reaches up to 36 Nm, while the stall torque exceeds 24 Nm, equivalent to stably lifting a 3.6 kg load. This provides strong and reliable power for load-bearing locomotion in quadruped robots and assisted rehabilitation in exoskeleton robots.

From industrial applications such as SCARA robot sorting and six-axis robotic arm loading and unloading, to medical applications including rehabilitation training equipment and surgical robot precision control, and further to consumer-level markets such as bionic robot gait simulation and UAV gimbal stabilization, the module supports multiple communication protocols, including CAN and RS485, enabling rapid compatibility with control systems from different brands.

More importantly, the combination of lightweight design and high torque density creates strong application versatility:

Small-size models can be embedded in UAV gimbals, ensuring smooth 360° rotation without increasing payload.

Larger models can be integrated into AGV drive wheels, supporting 24-hour continuous operation to meet the demands of uninterrupted warehouse and logistics operations.

The internal gears of the HONPINE planetary gear motor are made from high-strength alloy steel, treated with carburizing and quenching, achieving a surface hardness of HRC 58–62. Combined with food-grade lubricating grease, the service life exceeds 10,000 hours under rated operating conditions, equivalent to approximately 14 months of continuous industrial operation without replacing core components.

In addition, the motor features a modular sealing design with a protection rating of IP65, effectively resisting dust and liquid splashes, making it suitable for special environments such as food processing and automotive painting.

The standardized interfaces and detachable end-cap design allow maintenance without disassembling the entire robot—modules can be replaced directly, significantly reducing downtime and maintenance costs.

With the inherent advantages of planetary gear reducers, HONPINE planetary reducer motors are widely used across various robotic fields.

In quadruped robots, they meet the requirements of 12 degrees of freedom, providing stable and powerful drive for movement across complex terrain.

In robotic arms, the high-precision planetary reducer ensures accurate positioning, enabling complex tasks such as welding and cutting.

In humanoid robots, planetary reducers help achieve more natural and fluid movements, significantly improving coordination and stability in actions such as walking, arm lifting, and posture transitions.

Industry Trends

- 00

0000-00

OMG Ultra Compact Harmonic Drive Joint Module with Built-in Torque Sensor![OMG Ultra Compact Harmonic Drive Joint Module with Built-in Torque Sensor OMG Ultra Compact Harmonic Drive Joint Module with Built-in Torque Sensor]()

- 00

0000-00

The Role of Harmonic Drive Gears in Achieving 5–10 μm Accuracy in Dental Milling Machines![The Role of Harmonic Drive Gears in Achieving 5–10 μm Accuracy in Dental Milling Machines The Role of Harmonic Drive Gears in Achieving 5–10 μm Accuracy in Dental Milling Machines]()

- 00

0000-00

Why Harmonic Drive Strain Wave Reducers Are Ideal for Flexographic Printing Machine Registration Systems?![Why Harmonic Drive Strain Wave Reducers Are Ideal for Flexographic Printing Machine Registration Systems? Why Harmonic Drive Strain Wave Reducers Are Ideal for Flexographic Printing Machine Registration Systems?]()

- 00

0000-00

Why Are Harmonic Rotary Actuators Perfect for Medical Equipment?![Why Are Harmonic Rotary Actuators Perfect for Medical Equipment? Why Are Harmonic Rotary Actuators Perfect for Medical Equipment?]()

- 00

0000-00

Harmonic Drive Gearbox – Complete Introduction and Analysis![Harmonic Drive Gearbox – Complete Introduction and Analysis Harmonic Drive Gearbox – Complete Introduction and Analysis]()