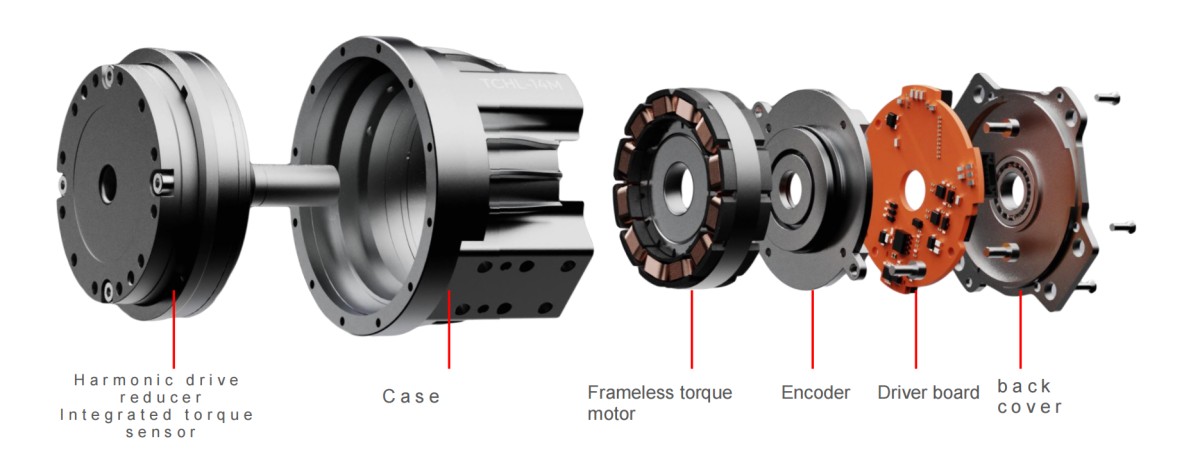

Human Robot Harmonic Joint Module with Torque Sensor and Integrated Cable Connector

● Introduction

The module features fully integrated cables and connectors, allowing fast, precise component connections and enabling safe, responsive motion control through a highly integrated design.

Multiple Connection Methods

This joint module support flexible and diverse installation options:Double-sided mounting,Single-sided mounting,Bilateral through fixation,Bottom mounting,Radial fixation,Rod fixation

Designer Speaking

Primarily developed for users in the field of embodied intelligence, this system features comprehensive mounting interfaces while significantly reducing joint volume and weight, allowing users to systematically reduce the weight and manufacturing complexity of connecting components. Furthermore, it integrates an output torque sensor without increasing the weight or volume of the joint, enabling the robot to achieve higher dynamic response performance, superior data acquisition quality, and greater load-carrying capacity.

Features of TCHL Harmonic Joint Module

Integrated force/torque sensor on the reducer side, enabling closed-loop force and position control

Fully integrated cables and connectors for simpler and more reliable robot wiring

Ultra-lightweight design: the 14-size model weighs only 0.5 kg

Innovatively integrated electrical connectors, supporting flexible and diverse installation configurations

Supports CAN and EtherCAT communication protocols

Integrated power supply and multi-protocol bus, capable of passing through the hollow shaft of size 14 and above

Specification

Sheet 1