High Precision Epicyclic Planetary Reducer Gearbox Manufacturer

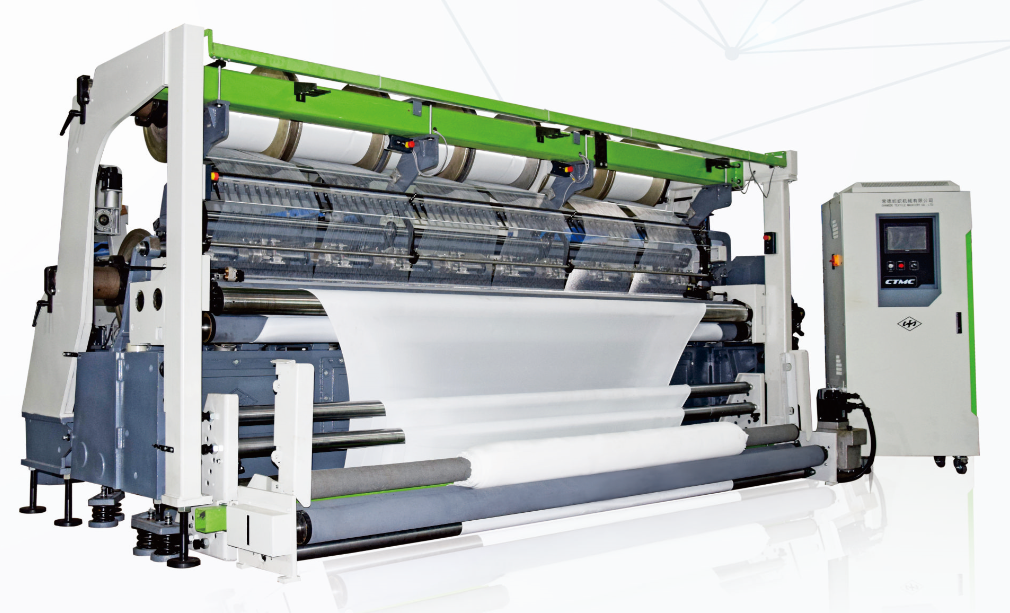

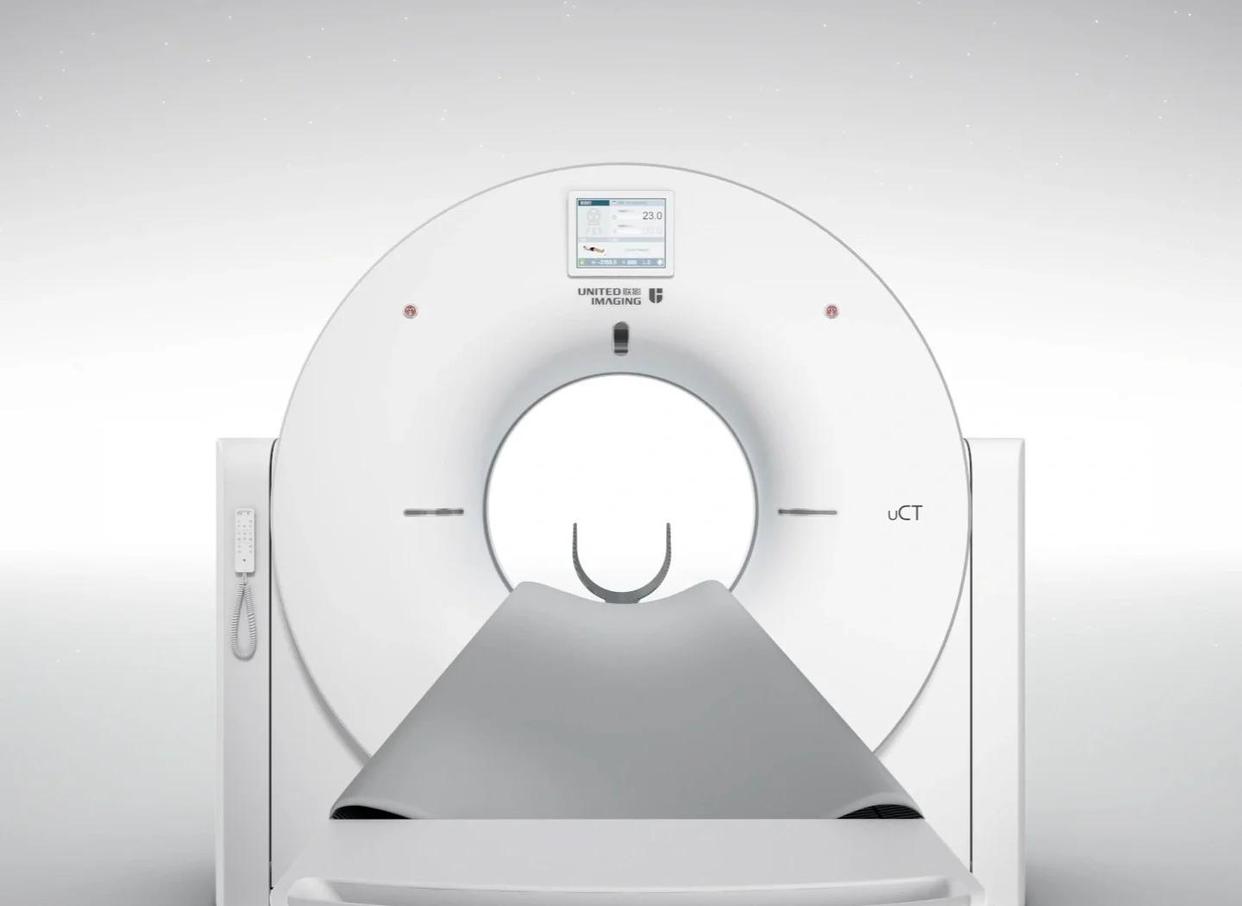

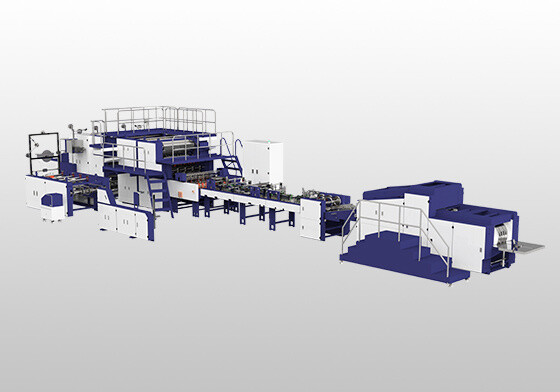

A planetary gearbox also called epicyclic gearbox.The planetary gearbox set is a series of various types of reducers based on planetary gearboxes that are commonly used. Our company primarily manufactures the following types within this series: planetary gearboxes,spiral bevel gearbox, and hollow rotary platforms.Planetary gearboxes are the standard basic type. Spiral bevel gearboxs and hollow rotary platforms can integrate standard planetary gearboxes, thus enriching their types and offering greater torque and a wider range of reduction ratios. These three common types of reducers are typically used in application fields such as precision machine tools, medical equipment, packaging equipment, logistics equipment, automation equipment, and 3C equipment.

Standard Planetary Reducer

A planetary gearbox primarily consists of a sun gear, planetary gears, an internal ring gear, and a planetary carrier. The input power drives the sun gear, causing the planetary gears to both revolve around the sun gear and rotate on their own axes, ultimately transmitting power through the planetary carrier. Multi-stage reduction is achieved by cascading multiple planetary gear sets, which meets the demand for higher transmission ratios while introducing slight variations in size and efficiency. Power is transferred via gear engagement, leveraging the power-splitting characteristic of planetary systems. Simultaneous multi-tooth engagement distributes loads, enhancing load-bearing capacity.Planetary gearboxes are further categorized by their output configurations and structural designs:shaft-output planetary gearbox,flange-output planetary gearbox,right-angle planetary gearbox.

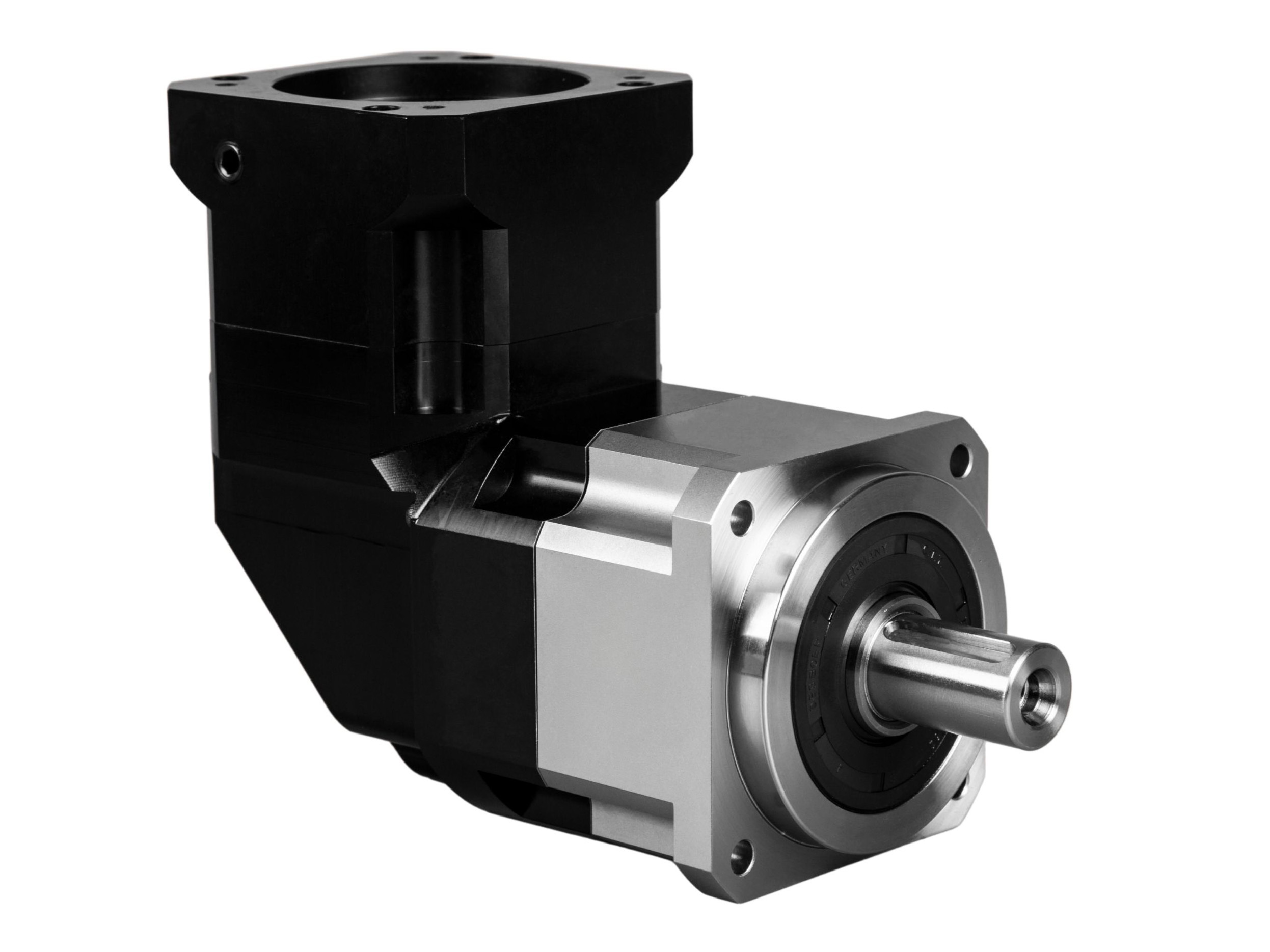

![Bevel Transmission Gear Drive Shaft Mounted Planetary Gearbox Bevel Transmission Gear Drive Shaft Mounted Planetary Gearbox]() Bevel Transmission Gear Drive Shaft Mounted Planetary GearboxThe Shaft-Output High-Load-Capacity Planetary Gear Drive is a compact transmission system with a vertical 90° input-output shaft configuration, both aligned on the same plane. The output end incorporates high-load tapered roller bearings to withstand extreme radial forces and overturning moments. Power transfer and speed reduction are achieved through multi-stage gear meshing, making it ideal for space-constrained industrial applications requiring vertical torque redirection, especially in machine tools with high overturning moment demands.Details

Bevel Transmission Gear Drive Shaft Mounted Planetary GearboxThe Shaft-Output High-Load-Capacity Planetary Gear Drive is a compact transmission system with a vertical 90° input-output shaft configuration, both aligned on the same plane. The output end incorporates high-load tapered roller bearings to withstand extreme radial forces and overturning moments. Power transfer and speed reduction are achieved through multi-stage gear meshing, making it ideal for space-constrained industrial applications requiring vertical torque redirection, especially in machine tools with high overturning moment demands.Details![Circular Flange high precision Reduction Planetary Gearbox Circular Flange high precision Reduction Planetary Gearbox]() Circular Flange high precision Reduction Planetary GearboxThe Shaft-Output Circular-Flange Planetary Gearbox is a planetary gear transmission system with a vertical 90-degree layout between the input and output shafts, both positioned on the same plane. The gearbox features a circular housing and a circular output flange. Power transmission and speed reduction are achieved through multi-stage gear meshing. Its compact and space-efficient design makes it ideal for general industrial applications with spatial constraints or requiring vertical input-output orientation.Details

Circular Flange high precision Reduction Planetary GearboxThe Shaft-Output Circular-Flange Planetary Gearbox is a planetary gear transmission system with a vertical 90-degree layout between the input and output shafts, both positioned on the same plane. The gearbox features a circular housing and a circular output flange. Power transmission and speed reduction are achieved through multi-stage gear meshing. Its compact and space-efficient design makes it ideal for general industrial applications with spatial constraints or requiring vertical input-output orientation.Details![Square Flange Speed Reduction Planetary Gear Transmisson System Square Flange Speed Reduction Planetary Gear Transmisson System]() Square Flange Speed Reduction Planetary Gear Transmisson SystemThe Shaft Output Square Flange Planetary Gearbox is a planetary gear transmission system with a vertical 90-degree layout between the input and output shafts, both positioned on the same plane. The gearbox features a square housing and a square output flange. Power transmission and speed reduction are achieved through multi-stage gear meshing. Its compact and space-efficient design makes it ideal for general industrial applications with spatial constraints or requiring vertical input-output orientation.Details

Square Flange Speed Reduction Planetary Gear Transmisson SystemThe Shaft Output Square Flange Planetary Gearbox is a planetary gear transmission system with a vertical 90-degree layout between the input and output shafts, both positioned on the same plane. The gearbox features a square housing and a square output flange. Power transmission and speed reduction are achieved through multi-stage gear meshing. Its compact and space-efficient design makes it ideal for general industrial applications with spatial constraints or requiring vertical input-output orientation.Details![90 Degree Input Output Roller Bearing Planetary Gearbox 90 Degree Input Output Roller Bearing Planetary Gearbox]() 90 Degree Input Output Roller Bearing Planetary GearboxThe Right Angle High Load Capacity Planetary Gearbox is a planetary gear transmission system with a vertical 90-degree layout between the input and output shafts, both positioned on the same plane. The output end is reinforced with high-load tapered roller bearings, enabling it to withstand greater radial forces and overturning moments. Power transmission and speed reduction are achieved through multi-stage gear meshing. Its compact and space-efficient design makes it ideal for general industrial applications with spatial constraints or requiring vertical input-output orientation, particularly suited for machine tools demanding high resistance to overturning moments.Details

90 Degree Input Output Roller Bearing Planetary GearboxThe Right Angle High Load Capacity Planetary Gearbox is a planetary gear transmission system with a vertical 90-degree layout between the input and output shafts, both positioned on the same plane. The output end is reinforced with high-load tapered roller bearings, enabling it to withstand greater radial forces and overturning moments. Power transmission and speed reduction are achieved through multi-stage gear meshing. Its compact and space-efficient design makes it ideal for general industrial applications with spatial constraints or requiring vertical input-output orientation, particularly suited for machine tools demanding high resistance to overturning moments.Details![Right Angle Round Frame Helical Bevel Planetary Gearbox Right Angle Round Frame Helical Bevel Planetary Gearbox]() Right Angle Round Frame Helical Bevel Planetary GearboxThe Right Angle Round Frame Planetary Gearbox is a planetary gear transmission system with a vertical 90-degree layout between the input and output shafts, both positioned on the same plane. The planetary gearbox features a circular housing and a circular output flange. Power transmission and speed reduction are achieved through multi-stage gear meshing. Its compact and space-efficient design makes it ideal for general industrial applications with spatial constraints or requiring vertical input-output orientation.Details

Right Angle Round Frame Helical Bevel Planetary GearboxThe Right Angle Round Frame Planetary Gearbox is a planetary gear transmission system with a vertical 90-degree layout between the input and output shafts, both positioned on the same plane. The planetary gearbox features a circular housing and a circular output flange. Power transmission and speed reduction are achieved through multi-stage gear meshing. Its compact and space-efficient design makes it ideal for general industrial applications with spatial constraints or requiring vertical input-output orientation.Details![Right Angle High Load Capacity Planetary Gearbox Right Angle High Load Capacity Planetary Gearbox]() Right Angle High Load Capacity Planetary GearboxThe Right Angle High Load Capacity Planetary Gearbox is a planetary gear transmission system with a vertical 90-degree layout between the input and output shafts, both positioned on the same plane. The output end is equipped with a flange plate. Power transmission and speed reduction are achieved through multi-stage gear meshing. Its small and space-efficient design makes it ideal for general industrial applications with spatial constraints or requiring vertical input-output orientation, particularly suited for machine tools demanding high resistance to overturning moments.Details

Right Angle High Load Capacity Planetary GearboxThe Right Angle High Load Capacity Planetary Gearbox is a planetary gear transmission system with a vertical 90-degree layout between the input and output shafts, both positioned on the same plane. The output end is equipped with a flange plate. Power transmission and speed reduction are achieved through multi-stage gear meshing. Its small and space-efficient design makes it ideal for general industrial applications with spatial constraints or requiring vertical input-output orientation, particularly suited for machine tools demanding high resistance to overturning moments.Details![High Precision Flange Output Planetary Gear Reducer High Precision Flange Output Planetary Gear Reducer]() High Precision Flange Output Planetary Gear ReducerThe flange output planetary gear reducer is a precision transmission device that combines a planetary gear transmission system with a flange output structure. Its core components consist of a sun gear, planet gears, and an internal ring gear, achieving power transmission through single-stage or multi-stage gear meshing. The flange, serving as a critical connection component, features a circular design with integrated high-precision bearings, providing enhanced contact area and stable mounting support. Compatible with power sources such as servo motors and stepper motors, this reducer is widely employed in precision equipment across CNC machine tools, industrial robots, automated production lines, and aerospace applications.Details

High Precision Flange Output Planetary Gear ReducerThe flange output planetary gear reducer is a precision transmission device that combines a planetary gear transmission system with a flange output structure. Its core components consist of a sun gear, planet gears, and an internal ring gear, achieving power transmission through single-stage or multi-stage gear meshing. The flange, serving as a critical connection component, features a circular design with integrated high-precision bearings, providing enhanced contact area and stable mounting support. Compatible with power sources such as servo motors and stepper motors, this reducer is widely employed in precision equipment across CNC machine tools, industrial robots, automated production lines, and aerospace applications.Details![Right Angle Square Housing Output Flange Planetary Reducer Right Angle Square Housing Output Flange Planetary Reducer]() Right Angle Square Housing Output Flange Planetary ReducerThe right angle square frame output planetary reducer is a planetary gear transmission device featuring a vertical 90 degree layout between input and output shafts, with both shafts lying on the same plane. Characterized by its square housing and square output flange, this reducer achieves power transmission and speed reduction through multi-stage gear meshing. It offers a compact structure and space-saving advantages, making it particularly suitable for general industrial applications requiring spatial constraints compliance or vertical input-output orientation arrangements.Details

Right Angle Square Housing Output Flange Planetary ReducerThe right angle square frame output planetary reducer is a planetary gear transmission device featuring a vertical 90 degree layout between input and output shafts, with both shafts lying on the same plane. Characterized by its square housing and square output flange, this reducer achieves power transmission and speed reduction through multi-stage gear meshing. It offers a compact structure and space-saving advantages, making it particularly suitable for general industrial applications requiring spatial constraints compliance or vertical input-output orientation arrangements.Details

Right-Angle Planetary Gearbox

A right-angle Spiral Bevel Gearbox is a transmission device with a 90-degree angle between input and output shafts, utilizing gear mechanisms such as spiral bevel gears or standard bevel gears to redirect power flow. The design prioritizes spatial optimization, and these gearboxes are further categorized by input configurations: bore-input and shaft-input models. They are widely used in industrial automation equipment, CNC machine tools, packaging machinery, and other applications requiring compact installation or directional power transmission.Housing Material Selection Guide:Aluminum Housing: Ideal for automation systems and weight-sensitive applications.Stainless Steel Housing: Designed for corrosion-resistant environments (food, pharmaceuticals, chemical, marine engineering).Alloy Steel Housing: Optimized for heavy-duty equipment and smart warehouse lifting systems.

![Shaft Input Right Angle 90 Degree Spiral Bevel Gearbox Shaft Input Right Angle 90 Degree Spiral Bevel Gearbox]() Shaft Input Right Angle 90 Degree Spiral Bevel GearboxA shaft-input right-angle spiral bevel gearbox features a shaft-input design, enabling flexible connection to power sources via couplings or other linkage mechanisms. The input and output shafts are oriented at a 90° angle, utilizing gear structures such as spiral bevel gears or standard bevel gears to redirect power. Its design prioritizes spatial optimization, making it ideal for industrial automation equipment, CNC machine tools, packaging machinery, and other applications requiring compact installation or directional power transmission.Housing Material Selection Guide:Aluminum Housing,Preferred for automation systems and weight-sensitive applications.Stainless Steel Housing,Designed for corrosion-resistant environments (food processing, pharmaceuticals, chemical, marine engineering).Alloy Steel Housing,Engineered for heavy-duty equipment and smart warehouse lifting systems.Details

Shaft Input Right Angle 90 Degree Spiral Bevel GearboxA shaft-input right-angle spiral bevel gearbox features a shaft-input design, enabling flexible connection to power sources via couplings or other linkage mechanisms. The input and output shafts are oriented at a 90° angle, utilizing gear structures such as spiral bevel gears or standard bevel gears to redirect power. Its design prioritizes spatial optimization, making it ideal for industrial automation equipment, CNC machine tools, packaging machinery, and other applications requiring compact installation or directional power transmission.Housing Material Selection Guide:Aluminum Housing,Preferred for automation systems and weight-sensitive applications.Stainless Steel Housing,Designed for corrosion-resistant environments (food processing, pharmaceuticals, chemical, marine engineering).Alloy Steel Housing,Engineered for heavy-duty equipment and smart warehouse lifting systems.Details![Compact Bore Input Right Angle 90-degree Spiral Bevel Gearbox Compact Bore Input Right Angle 90-degree Spiral Bevel Gearbox]() Compact Bore Input Right Angle 90-degree Spiral Bevel GearboxA bore-input right angle spiral bevel gearbox features an input shaft with a bore design and a connecting flange plate for direct motor coupling. Its input and output shafts are arranged at a 90-degree angle, achieving power redirection through gear mechanisms such as spiral bevel gears or bevel gears. The core design focuses on optimizing spatial efficiency, making it suitable for industrial automation equipment, CNC machine tools, packaging machinery, and other applications requiring compact installation or directional power transmission. Depending on specific operational demands, housing materials vary: aluminum housings are prioritized for automated systems and weight-sensitive scenarios; stainless steel housings cater to corrosion-resistant environments like food processing, pharmaceuticals, and marine engineering; alloy steel housings are engineered for heavy-duty applications such as smart warehouse lifting systems. Clients must communicate their operational context and material requirements to manufacturers during selection to ensure optimal gearbox performance.Details

Compact Bore Input Right Angle 90-degree Spiral Bevel GearboxA bore-input right angle spiral bevel gearbox features an input shaft with a bore design and a connecting flange plate for direct motor coupling. Its input and output shafts are arranged at a 90-degree angle, achieving power redirection through gear mechanisms such as spiral bevel gears or bevel gears. The core design focuses on optimizing spatial efficiency, making it suitable for industrial automation equipment, CNC machine tools, packaging machinery, and other applications requiring compact installation or directional power transmission. Depending on specific operational demands, housing materials vary: aluminum housings are prioritized for automated systems and weight-sensitive scenarios; stainless steel housings cater to corrosion-resistant environments like food processing, pharmaceuticals, and marine engineering; alloy steel housings are engineered for heavy-duty applications such as smart warehouse lifting systems. Clients must communicate their operational context and material requirements to manufacturers during selection to ensure optimal gearbox performance.Details

Hollow Rotating Table

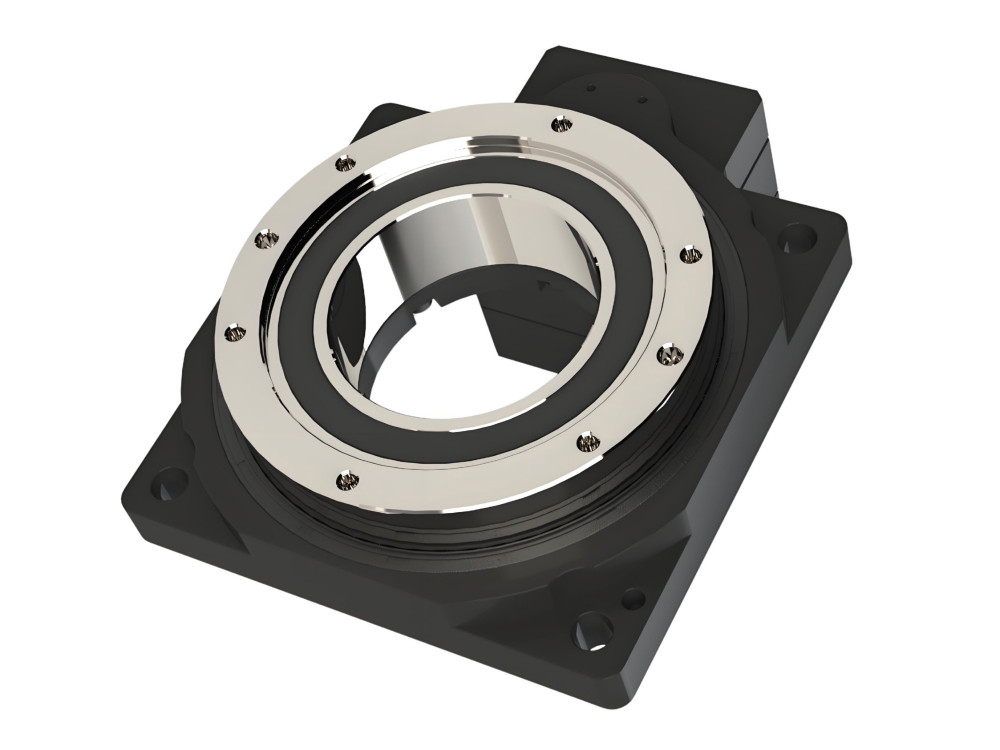

The hollow rotary table is an integrated device combining precision transmission and positioning capabilities. Its core design features a hollow structure, allowing pipelines (e.g., air tubes, electrical cables) to pass through the center of the turntable, resolving cable entanglement issues common in traditional rotary mechanisms. Driven by a servo motor, the platform achieves high-precision angular control through gear reduction or worm gear transmission, delivering high rigidity and repeat positioning accuracy. It serves as a high-performance alternative to direct-drive (DD) motors and cam indexers. Based on structural configurations, hollow rotary tables are categorized into:Standard Hollow Rotary Table,Planetary Hollow Rotary Table,Right-Angle Hollow Rotary Table.Through structural optimization and precision manufacturing, hollow rotary tables significantly enhance efficiency and accuracy in automated equipment upgrades, making them a core solution for precision rotary positioning in modern industries. They are widely used in industrial automation, robotics, medical equipment, and related fields.

![Right Angle Bevel Gear Hollow Rotary Table Right Angle Bevel Gear Hollow Rotary Table]() Right Angle Bevel Gear Hollow Rotary TableThe right-angle hollow rotary table is an enhanced version of the standard hollow rotary table, incorporating an integrated right-angle bevel gear set to redirect the input orientation for space optimization. Its core hollow structure allows pipelines (e.g., air tubes, electrical cables) to pass through the turntable’s center, resolving cable entanglement issues common in traditional rotary mechanisms. Driven by a servo motor, the platform utilizes gear reduction or worm gear transmission to achieve high-precision angular control, while delivering exceptional rigidity and repeat positioning accuracy.Details

Right Angle Bevel Gear Hollow Rotary TableThe right-angle hollow rotary table is an enhanced version of the standard hollow rotary table, incorporating an integrated right-angle bevel gear set to redirect the input orientation for space optimization. Its core hollow structure allows pipelines (e.g., air tubes, electrical cables) to pass through the turntable’s center, resolving cable entanglement issues common in traditional rotary mechanisms. Driven by a servo motor, the platform utilizes gear reduction or worm gear transmission to achieve high-precision angular control, while delivering exceptional rigidity and repeat positioning accuracy.Details![Worm Gear Transmission Planetary Hollow Rotary Table Worm Gear Transmission Planetary Hollow Rotary Table]() Worm Gear Transmission Planetary Hollow Rotary TableA planetary hollow rotary table is an integrated system combining a planetary gear reducer with a hollow rotary platform, offering a wider range of gear ratios tailored to specific applications. Its core design features a hollow structure, allowing pipelines (e.g., air tubes, electrical cables) to pass through the center of the turntable, eliminating the cable entanglement issues common in traditional rotary mechanisms. Driven by a servo motor, the platform achieves high-precision angular control through gear reduction or worm gear transmission, delivering exceptional rigidity and repeat positioning accuracy.Details

Worm Gear Transmission Planetary Hollow Rotary TableA planetary hollow rotary table is an integrated system combining a planetary gear reducer with a hollow rotary platform, offering a wider range of gear ratios tailored to specific applications. Its core design features a hollow structure, allowing pipelines (e.g., air tubes, electrical cables) to pass through the center of the turntable, eliminating the cable entanglement issues common in traditional rotary mechanisms. Driven by a servo motor, the platform achieves high-precision angular control through gear reduction or worm gear transmission, delivering exceptional rigidity and repeat positioning accuracy.Details![Serve Motor Drive High Precision Standard Hollow Rotary Platform Serve Motor Drive High Precision Standard Hollow Rotary Platform]() Serve Motor Drive High Precision Standard Hollow Rotary PlatformThe standard hollow rotary platform is an integrated device combining precision transmission and positioning functions. Its core design features a hollow structure, allowing pipelines (such as tubes and wires) to pass through the center of the rotating table. It can be directly connected to a servo motor. Driven by a servo motor and utilizing gear reduction, this platform achieves high-precision angular control and boasts characteristics such as high rigidity and high repetitive positioning accuracy. It can serve as a replacement for DD motors and cam dividers.Details

Serve Motor Drive High Precision Standard Hollow Rotary PlatformThe standard hollow rotary platform is an integrated device combining precision transmission and positioning functions. Its core design features a hollow structure, allowing pipelines (such as tubes and wires) to pass through the center of the rotating table. It can be directly connected to a servo motor. Driven by a servo motor and utilizing gear reduction, this platform achieves high-precision angular control and boasts characteristics such as high rigidity and high repetitive positioning accuracy. It can serve as a replacement for DD motors and cam dividers.Details

Planetary Gearbox - FAQ

Rigidity focuses on deformation.

Under load, how much does the shaft bend? How much does the gear meshing clearance increase? Rigidity directly determines a machine’s positioning accuracy and dynamic response.

If rigidity is insufficient, a robot performing precision movements will behave like it has “Parkinson’s disease” — shaking, vibrating, and never accurately reaching its target.

Strength, on the other hand, concerns whether the gearbox will fail.

It relates to the maximum stress the material can withstand and whether components may crack, deform, or collapse. Strength defines the service life and safety margin of the equipment.

Insufficient strength leads to a classic “brute force failure,” where internal components catastrophically break apart.

When selecting a planetary gearbox, focusing only on reduction ratio and price is far from enough. You must also evaluate:

Rated torque – continuous operating capability

Peak torque – ability to withstand shock loads

Service factor – compensation for harsh working conditions

For intelligent equipment with frequent start-stop cycles, peak torque is especially critical.

We can provide professional selection guidance and complete technical documentation. Ultimately, system-level reliability matters more than any single outstanding parameter. True performance depends on design, materials, manufacturing processes, and—most importantly—how well the gearbox matches real operating conditions.

The advantage lies in its structure.

Planetary gearboxes use a planetary gear system consisting of a central sun gear, surrounding planet gears, and an outer ring gear. This configuration enables power splitting and multi-tooth meshing, resulting in:Compact size,Lightweight design,High load capacity,Excellent rigidity.These characteristics make planetary gearboxes particularly suitable for automation equipment with strict space and performance requirements.

Three practical checks can help:Gear material and machining accuracy – ground gears are superior to hobbed gears.No-load backlash and noise – lower backlash and smoother operation indicate better quality.Temperature rise – excessive temperature increase after long-term operation (e.g., above 45°C) may indicate design or manufacturing defects.

Planetary gearboxes offer higher precision and efficiency, making them ideal for reciprocating and high-accuracy motion.Worm gear reducers provide large reduction ratios and self-locking capability, suitable for high-ratio and intermittent load applications, but typically suffer from lower efficiency.

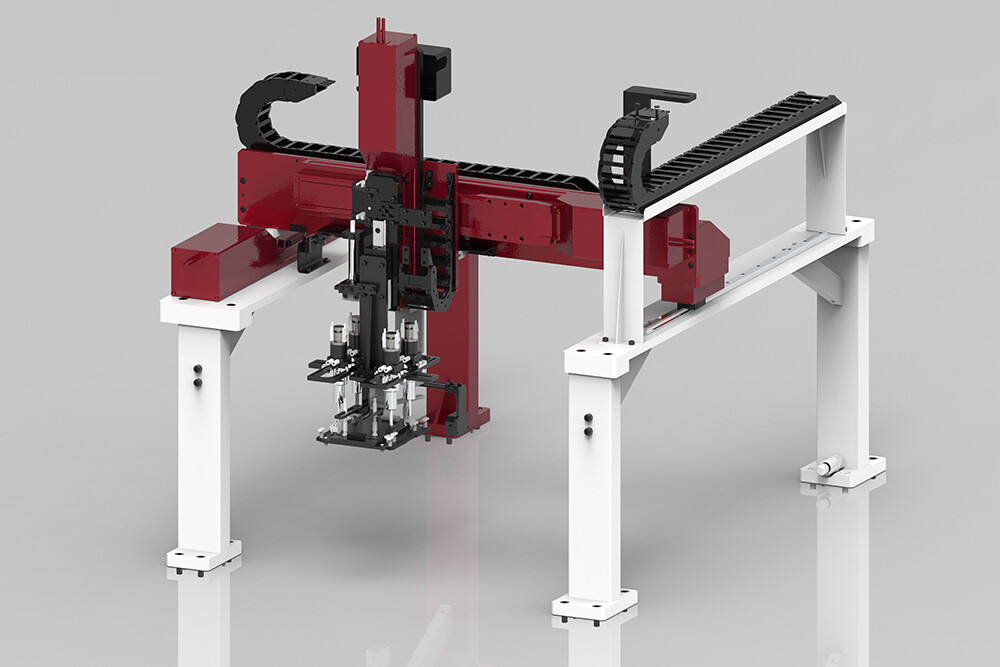

HONPINE planetary gearboxes have been widely applied and market-validated in industries such as:CNC machine tools,Mobile robots,New energy vehicles,Aerospace,Construction machinery,Photovoltaic equipment,3C electronics,Smart home systems,Medical devices.Driven by application demands, HONPINE continues to innovate toward higher precision, lighter weight, and higher power density, steadily positioning itself as an industry leader.

Yes. HONPINE has achieved full in-house R&D and manufacturing of planetary gearboxes.

Key processes—including gear machining, planetary carrier manufacturing, internal ring gear processing, and planet gear production—are all completed within HONPINE’s factory.

By integrating refined gear design, high-precision manufacturing processes, advanced load-sharing technology, and scientifically optimized lubrication, HONPINE systematically improves transmission efficiency and meets the stringent requirements of modern high-end equipment for energy efficiency, reliability, and long service life.

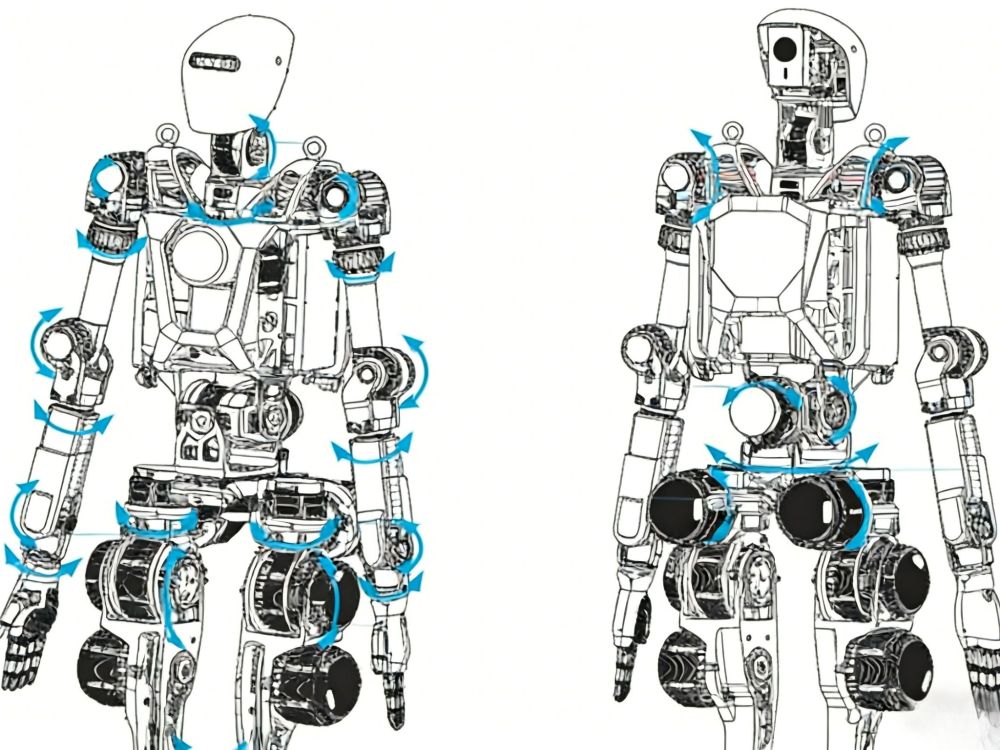

Take robot joints as an example. Servo motors typically operate at 3000–6000 rpm, while robot joints require speeds of only tens of rpm, along with significantly higher torque to drive robotic arms.

Planetary gearboxes convert the motor’s high speed into the low speed required by the joint while multiplying torque dozens of times, ensuring precise positioning and sufficient load capacity.

Similarly, in CNC machine spindle drives and conveyor power transmission systems, planetary gearboxes play a vital role. Their high transmission efficiency (typically 90%–97%) helps reduce energy consumption and enhance overall system stability.

1. Basic Definition

The reduction ratio is the ratio between input speed and output speed:

i = n₁ / n₂

Where:

n₁ = input speed

n₂ = output speed

Example:

If the input speed is 1500 rpm and the output speed is 25 rpm:

i = 1500 / 25 = 60:1

2. Gear Train Calculation Method

For multi-stage gear reducers, divide the number of teeth on the driven gear by that of the driving gear for each meshing pair, then multiply all results together.

Example (Planetary Gear System):

If:

Sun gear teeth = z₁

Planet gear teeth = z₂

Ring gear teeth = z₃

Then the reduction ratio can be expressed as:

i = (z₃ / z₁) × (z₂ / z₁)

Why Choose HONPINE Precision Planetary Reducer Gearbox

● HONPINE's precision planetary reducer gearbox features a monolithic housing design with the internal ring gear integrated into the front housing, structurally optimizing connection points to ensure precision during high-speed operation. The housing surface is nickel-plated for enhanced corrosion resistance in harsh operating conditions.

● The integrated planetary carrier and output shaft frame design eliminates precision loss from secondary connections. Through single clamping and machining, perfect coaxiality of the planetary carrier is achieved, ensuring smooth and efficient operation of the planetary gear system.

● The integrated sun gear and input shaft design reduces mechanical connection points, improving torque transmission performance while maintaining the overall precision of the reducer.

● HONPINE emphasizes material selection for its precision planetary reducer gearbox. The gears are manufactured from custom-made Japanese Cr-Mn-Ti (chromium-manganese-titanium) alloy steel.

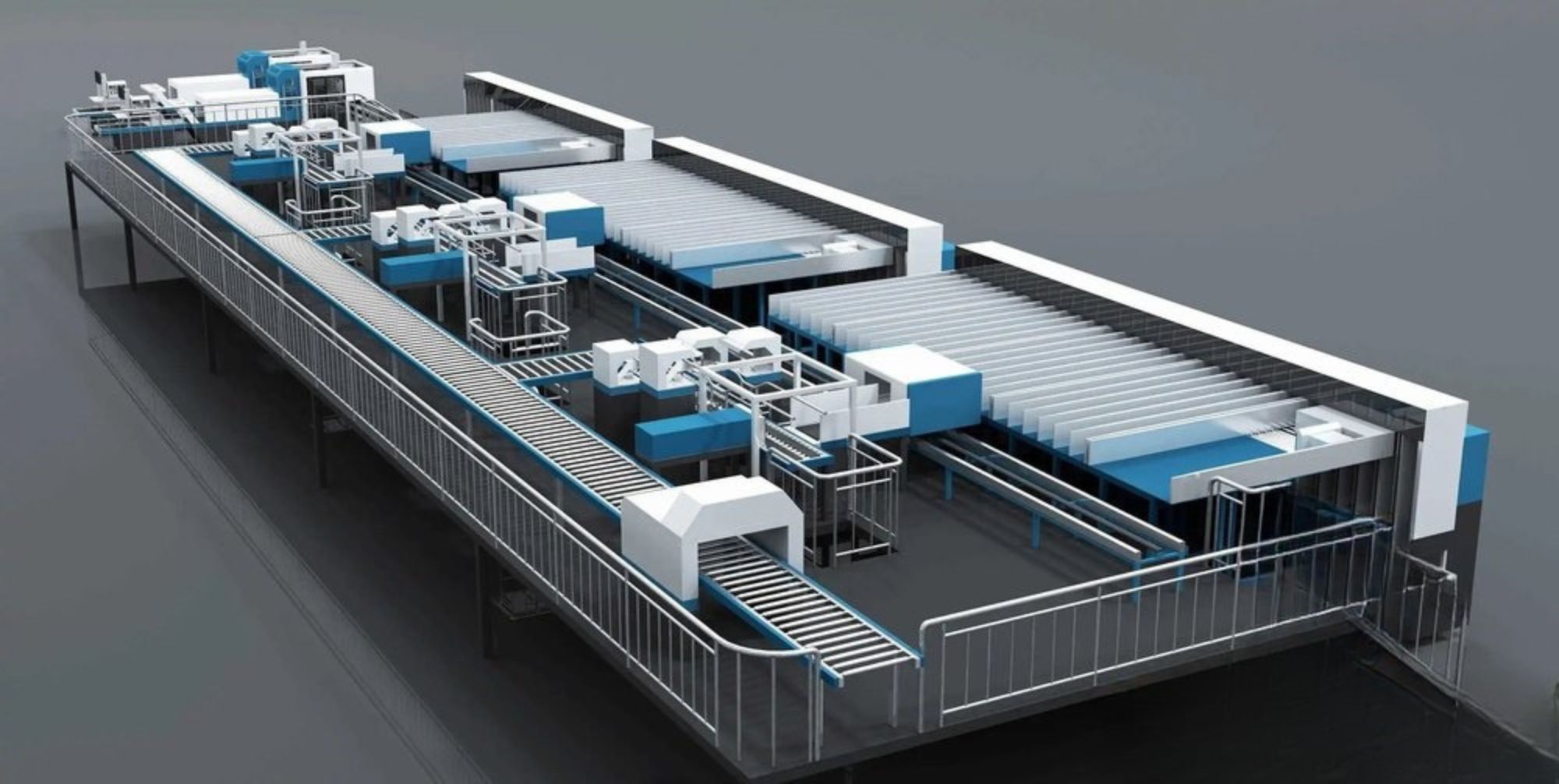

Application of Precision Planetary Reducer Gearbox

Planetary gearboxes deliver high torque, exceptional rigidity, and efficient power transmission in a compact design. Based on a planetary gear structure, they offer excellent load distribution and reliability for a wide range of motion control applications.

We provide two series to meet diverse needs: the Precision Series for high-accuracy scenarios requiring minimal backlash and superior positioning performance, and the Economic Series for cost-sensitive applications.

Ideal for use in robotics, automation, CNC machinery, material handling, and automotive systems, our planetary gearboxes ensure smooth operation and long service life across various industries.

Choose from standard or customized solutions to fit your specific requirements.

HONPINE NEWS

- 00

0000-00

HONPINE 2026 Chinese New Year Holiday Notice![HONPINE 2026 Chinese New Year Holiday Notice HONPINE 2026 Chinese New Year Holiday Notice]()

- 00

0000-00

A Complete Guide to Choosing Single-Encoder vs. Dual-Encoder Robot Joint Actuators![A Complete Guide to Choosing Single-Encoder vs. Dual-Encoder Robot Joint Actuators A Complete Guide to Choosing Single-Encoder vs. Dual-Encoder Robot Joint Actuators]()

- 00

0000-00

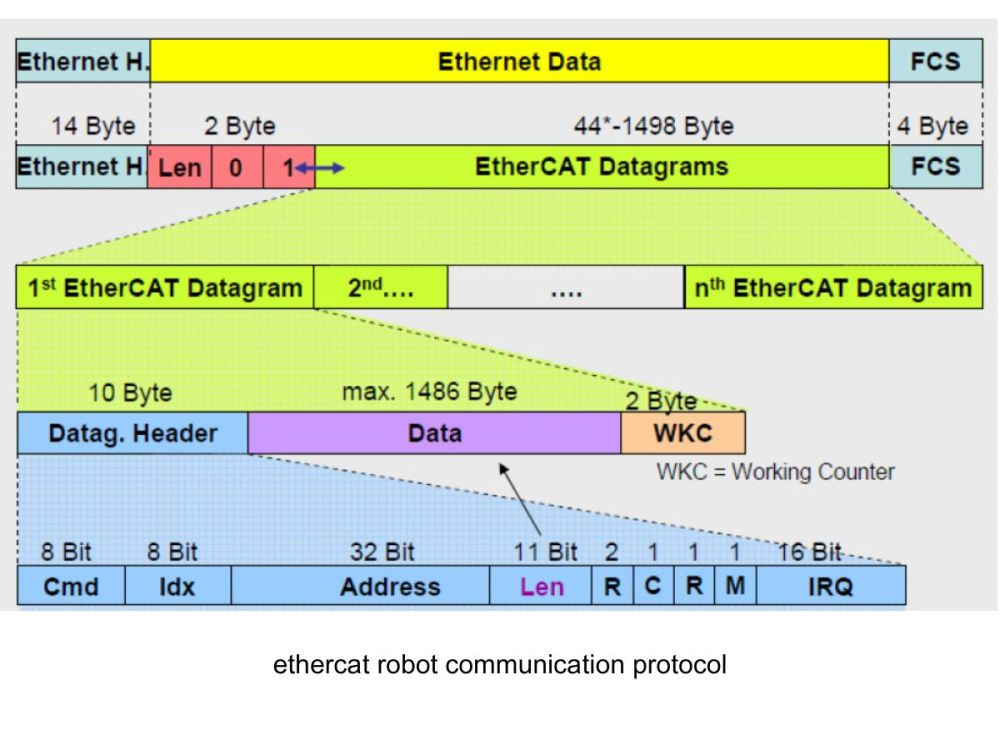

Robot Communication Protocols: Why EtherCAT and CAN Are the Future![Robot Communication Protocols: Why EtherCAT and CAN Are the Future Robot Communication Protocols: Why EtherCAT and CAN Are the Future]()

- 00

0000-00

Why Is It So Difficult for the Price of High-Performance Humanoid Robots to Decrease?And Why Are Harmonic Joint Modules Still Irreplaceable?![Why Is It So Difficult for the Price of High-Performance Humanoid Robots to Decrease?And Why Are Harmonic Joint Modules Still Irreplaceable? Why Is It So Difficult for the Price of High-Performance Humanoid Robots to Decrease?And Why Are Harmonic Joint Modules Still Irreplaceable?]()

- 00

0000-00

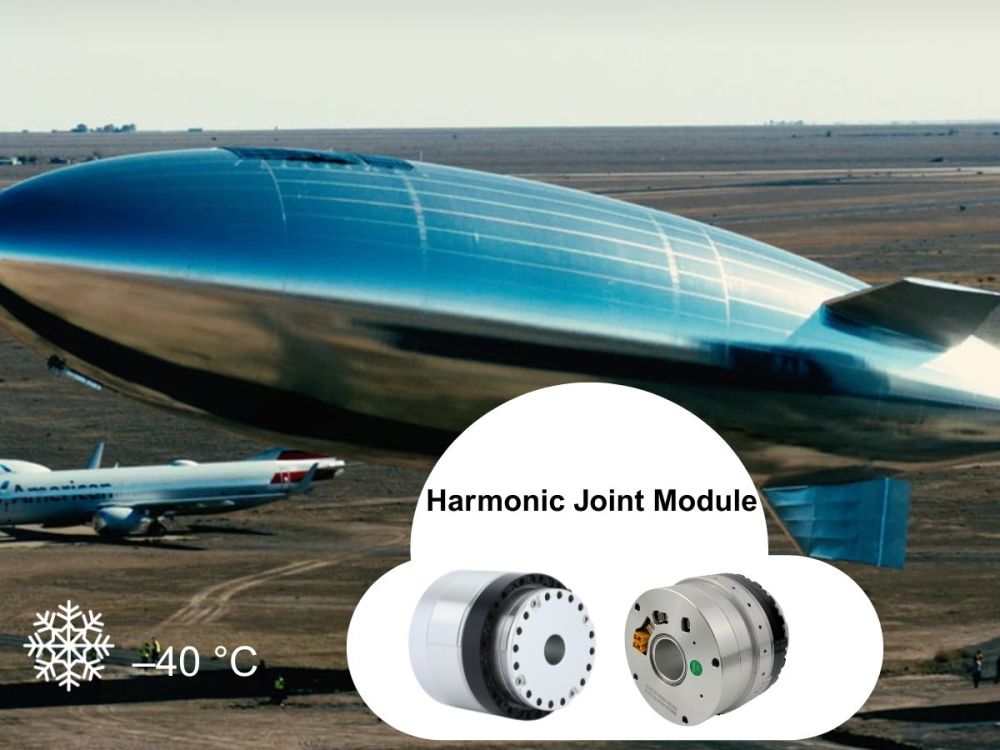

HONPINE Harmonic Joint Modules Empower Airplanes & Drones to Operate in the Stratosphere and Extreme Space-Like Environments![HONPINE Harmonic Joint Modules Empower Airplanes & Drones to Operate in the Stratosphere and Extreme Space-Like Environments HONPINE Harmonic Joint Modules Empower Airplanes & Drones to Operate in the Stratosphere and Extreme Space-Like Environments]()