Frameless Torque Motor Encoder Harmonic Drive Servo Rotary Actuator Company

Precision Harmonic Drive Rotary Actuators

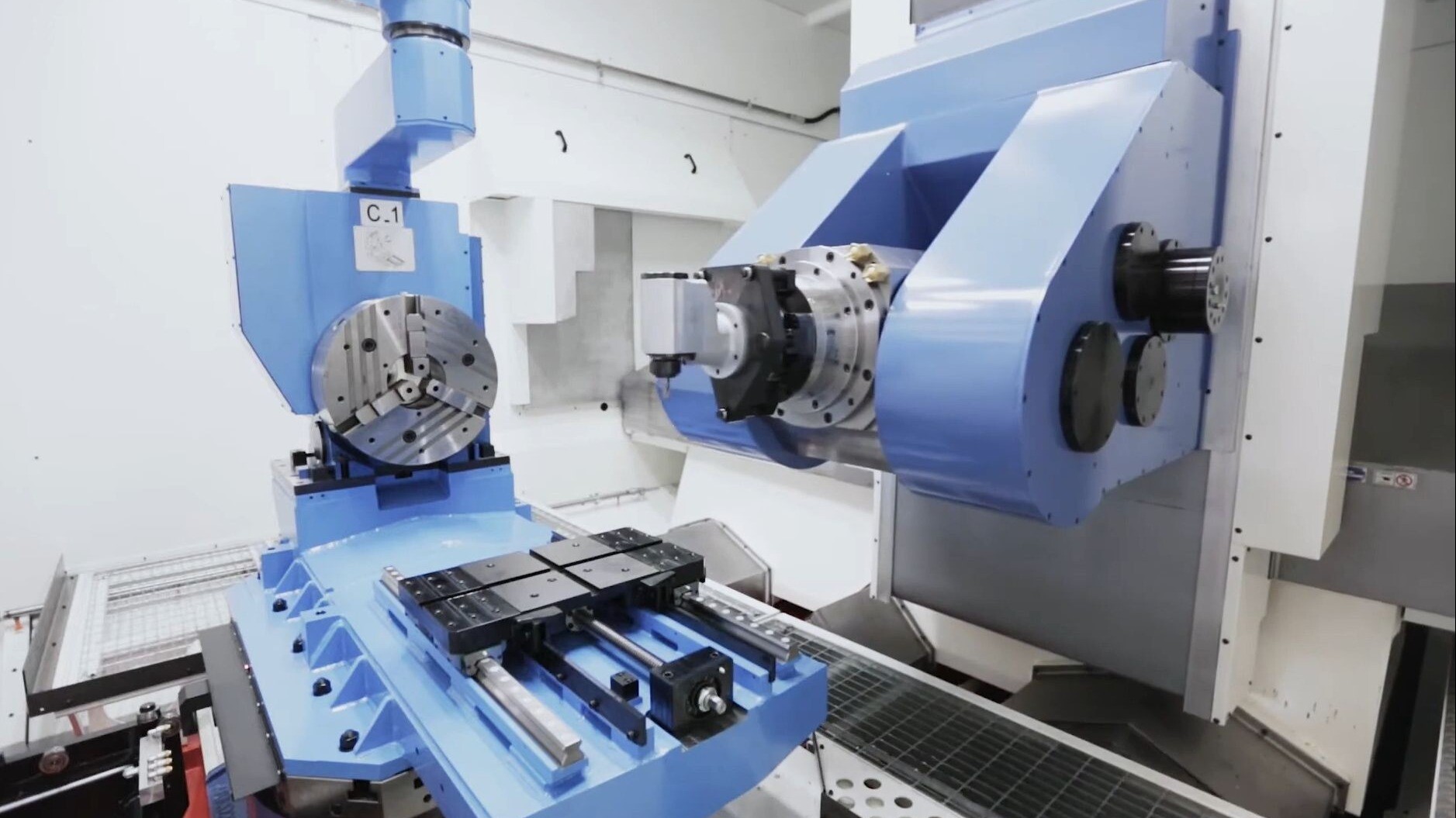

The rotary actuator is a power unit specifically designed for precision machine tools, industrial automation, and semiconductor applications. It typically integrates an inner-rotor frameless torque motor with components such as a reducer and encoder to form a complete rotary actuator unit. The control unit (driver) usually adopts an external drive configuration to achieve high-precision motion control for connected equipment.

Harmonic Drive Servo Actuator offer flexible voltage compatibility, supporting both high-voltage AC220V and low-voltage DC48V power inputs. They are widely used in fields requiring high precision and compact spatial integration, such as:Precision machine tool rotary tables,High-accuracy medical devices,5-axis laser cutting systems,Semiconductor manufacturing equipment.

Based on technical design differences, rotary actuators are categorized into two main types:

Robot Rotary Actuators

Standard Rotary Actuators

![Human Robot Harmonic Joint Module with Torque Sensor and Integrated Cable Connector Human Robot Harmonic Joint Module with Torque Sensor and Integrated Cable Connector]() Human Robot Harmonic Joint Module with Torque Sensor and Integrated Cable ConnectorThe TCHL Harmonic Joint Module is a harmonic joint module that integrates a torque sensor directly into the harmonic drive reducer. The torque sensor enables precise measurement of the drive system’s operating status and required torque values, allowing accurate load detection of the actuator. This helps prevent overload and enables safer human–robot interaction.

Human Robot Harmonic Joint Module with Torque Sensor and Integrated Cable ConnectorThe TCHL Harmonic Joint Module is a harmonic joint module that integrates a torque sensor directly into the harmonic drive reducer. The torque sensor enables precise measurement of the drive system’s operating status and required torque values, allowing accurate load detection of the actuator. This helps prevent overload and enables safer human–robot interaction.

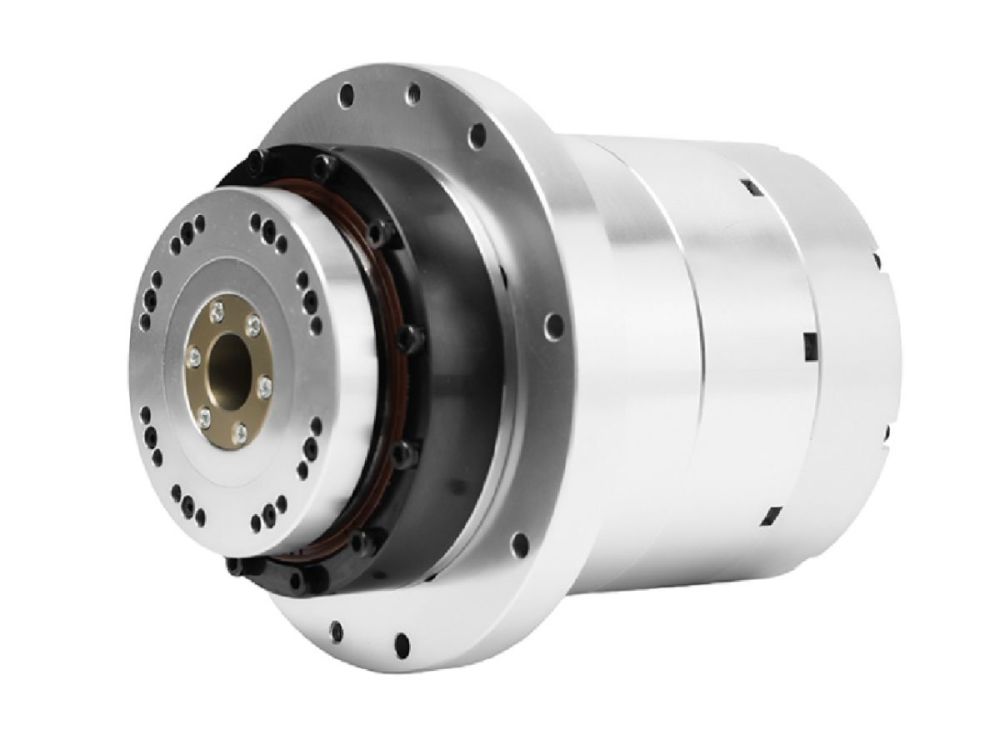

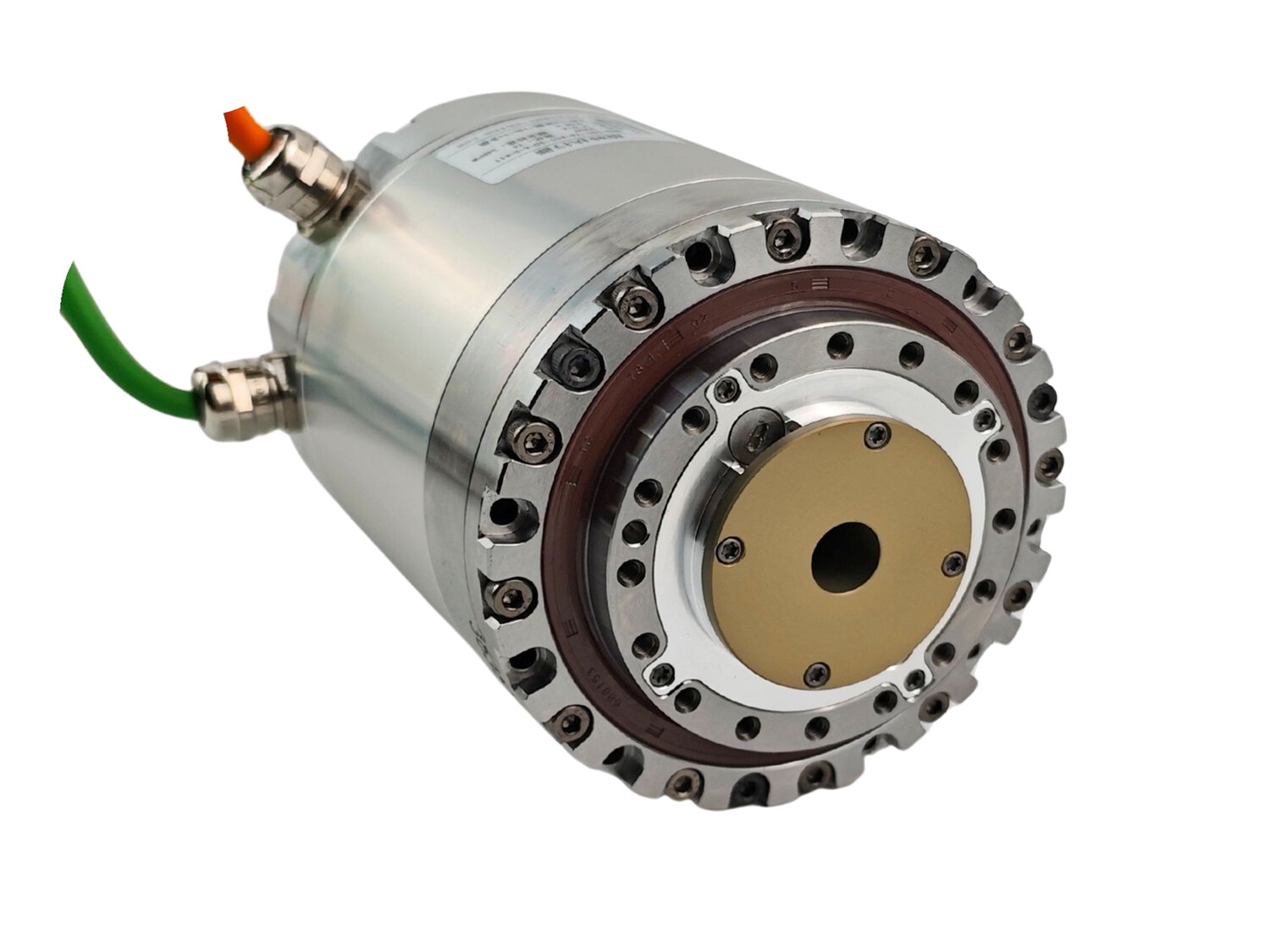

The module features fully integrated cables and connectors, allowing fast, precise component connections and enabling safe, responsive motion control through a highly integrated design.Details![Integrated Flange Harmonic Servo Rotary Actuators for Axial and Radial Loads Integrated Flange Harmonic Servo Rotary Actuators for Axial and Radial Loads]() Integrated Flange Harmonic Servo Rotary Actuators for Axial and Radial LoadsThe HATF Harmonic Servo Rotary Actuators support harmonic drives of models 11, 14, 17, 20, 25, 32, 40, 50, and 58, with rated torque from 4 N·m to 1200 N·m. They feature multi-turn absolute encoders with Tamagawa protocol: single-turn 17-bit / multi-turn 16-bit, or single-turn 23-bit / multi-turn 16-bit. Dual-encoder configurations are also available.Based on the HAS solid model, the HATF actuators add an integrated flange, allowing mounting when end-face installation is not possible. This design provides better support for axial and radial loads, while enhancing vibration and impact resistance.Details

Integrated Flange Harmonic Servo Rotary Actuators for Axial and Radial LoadsThe HATF Harmonic Servo Rotary Actuators support harmonic drives of models 11, 14, 17, 20, 25, 32, 40, 50, and 58, with rated torque from 4 N·m to 1200 N·m. They feature multi-turn absolute encoders with Tamagawa protocol: single-turn 17-bit / multi-turn 16-bit, or single-turn 23-bit / multi-turn 16-bit. Dual-encoder configurations are also available.Based on the HAS solid model, the HATF actuators add an integrated flange, allowing mounting when end-face installation is not possible. This design provides better support for axial and radial loads, while enhancing vibration and impact resistance.Details![Space Limited Hollow Shaft Harmonic Drive Dual Encoder Rotary Actuator Space Limited Hollow Shaft Harmonic Drive Dual Encoder Rotary Actuator]() Space Limited Hollow Shaft Harmonic Drive Dual Encoder Rotary ActuatorThe HAT Hollow and Standard Harmonic Servo Rotary Actuators support harmonic drives of models 11, 14, 17, 20, 25, 32, 40, 50, and 58, with rated torque from 4 N·m to 1200 N·m and outer diameters ranging from 62 mm to 220 mm.They feature multi-turn absolute encoders with Tamagawa protocol:Single-turn 17-bit, multi-turn 16-bit, or Single-turn 23-bit, multi-turn 16-bit.Custom dual-encoder configurations are also available. The harmonic actuators can be directly mounted via the end face, making them ideal for lightweight or space-constrained applications.Details

Space Limited Hollow Shaft Harmonic Drive Dual Encoder Rotary ActuatorThe HAT Hollow and Standard Harmonic Servo Rotary Actuators support harmonic drives of models 11, 14, 17, 20, 25, 32, 40, 50, and 58, with rated torque from 4 N·m to 1200 N·m and outer diameters ranging from 62 mm to 220 mm.They feature multi-turn absolute encoders with Tamagawa protocol:Single-turn 17-bit, multi-turn 16-bit, or Single-turn 23-bit, multi-turn 16-bit.Custom dual-encoder configurations are also available. The harmonic actuators can be directly mounted via the end face, making them ideal for lightweight or space-constrained applications.Details![Integrated Flange Harmonic Drive Servo Rotary Actuator Integrated Flange Harmonic Drive Servo Rotary Actuator]() Integrated Flange Harmonic Drive Servo Rotary ActuatorThe HASF Solid Standard Harmonic Servo Rotary Actuator includes harmonic drives of models 11, 14, 17, 20, and 25, with rated torque from 4 N·m to 133 N·m. It features a multi-turn absolute encoder with Tamagawa protocol: single-turn 23-bit, multi-turn 16-bit.Based on the standard HASF solid model, this version adds an integrated flange, allowing mounting when end-face installation is not possible. The flange provides better support for axial and radial loads and enhances vibration and impact resistance.Details

Integrated Flange Harmonic Drive Servo Rotary ActuatorThe HASF Solid Standard Harmonic Servo Rotary Actuator includes harmonic drives of models 11, 14, 17, 20, and 25, with rated torque from 4 N·m to 133 N·m. It features a multi-turn absolute encoder with Tamagawa protocol: single-turn 23-bit, multi-turn 16-bit.Based on the standard HASF solid model, this version adds an integrated flange, allowing mounting when end-face installation is not possible. The flange provides better support for axial and radial loads and enhances vibration and impact resistance.Details![Harmonic Drive Frameless Torque Motor Precision Encoder Rotary Actuator Harmonic Drive Frameless Torque Motor Precision Encoder Rotary Actuator]() Harmonic Drive Frameless Torque Motor Precision Encoder Rotary ActuatorThe HAS Solid Standard Harmonic Rotary Actuator integrates a frameless torque motor, multi-turn absolute encoder, and harmonic drive. It supports five harmonic drive models: 11, 14, 17, 20, and 25, with rated torque from 4 N·m to 133 N·m and outer diameters ranging from 62 mm to 110 mm.

Harmonic Drive Frameless Torque Motor Precision Encoder Rotary ActuatorThe HAS Solid Standard Harmonic Rotary Actuator integrates a frameless torque motor, multi-turn absolute encoder, and harmonic drive. It supports five harmonic drive models: 11, 14, 17, 20, and 25, with rated torque from 4 N·m to 133 N·m and outer diameters ranging from 62 mm to 110 mm.

It features a multi-turn absolute encoder with Tamagawa protocol: single-turn 23-bit, multi-turn 16-bit. The actuator can be directly mounted via the end face, making it ideal for lightweight or space-constrained applications.Details![High Torque Compact Integrated Harmonic Drive Rotary Actuators High Torque Compact Integrated Harmonic Drive Rotary Actuators]() High Torque Compact Integrated Harmonic Drive Rotary ActuatorsStandard rotary actuators typically integrate frameless inner rotor torque motors with harmonic drives and absolute encoders to form a complete rotary actuator unit. The control component (drive unit) usually adopts an external configuration to enable high-precision motion control of connected equipment. These actuators are commonly applied in fields requiring high precision and space efficiency, such as:machine tool rotary tables,precision medical equipment,5-axis laser cutting systems,semiconductor manufacturing equipment.Details

High Torque Compact Integrated Harmonic Drive Rotary ActuatorsStandard rotary actuators typically integrate frameless inner rotor torque motors with harmonic drives and absolute encoders to form a complete rotary actuator unit. The control component (drive unit) usually adopts an external configuration to enable high-precision motion control of connected equipment. These actuators are commonly applied in fields requiring high precision and space efficiency, such as:machine tool rotary tables,precision medical equipment,5-axis laser cutting systems,semiconductor manufacturing equipment.Details

Large Hollow Rotary Actuators

High Precision Rotary Actuators

Servo Driven Rotary Actuators

Application of Harmonic Drive Servo Rotary Actuator

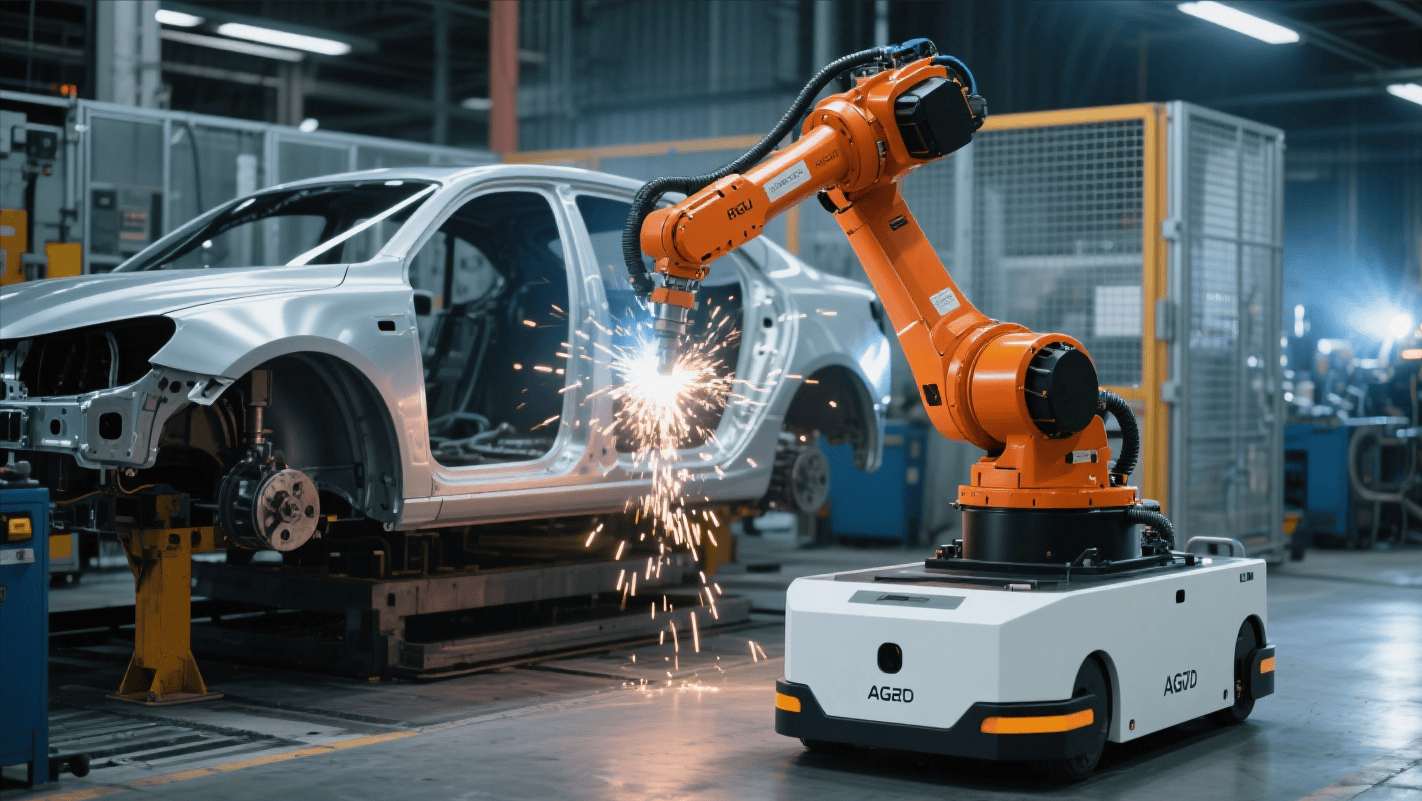

Harmonic Drive Rotary Actuator integrates a high-precision harmonic reducer, encoder, and frameless torque motor. Compatible with mainstream external drives, it ensures stable performance and long-term accuracy. The large hollow shaft simplifies cable routing. Its modular design enables easy, low-cost maintenance, even after the reducer's service life. Rated IP65 (IP67 optional), it is fully sealed, easy to install, and ready to use. The 220V version suits CNC machine tools, 3C equipment, laser processing, and medical devices, while the 48V model fits robotic joints, AGVs, and PTZ cameras.

Harmonic Servo Rotary Actuator - FAQ

A harmonic rotary actuator is an AC servo rotary actuator that integrates a high-torque precision harmonic reducer, a frameless torque motor, an optional hollow-shaft multi-turn absolute optical encoder, an electromagnetic brake, and a servo drive into one compact unit.

Harmonic rotary actuators offer stable performance with a precision retention life of more than 15,000 hours.

With a direct-drive integrated design and a fully sealed structure, installation is simple and truly plug-and-play.

For applications with limited space, heavy loads, and high precision requirements, harmonic mechatronic actuators provide an ideal solution.

Harmonic servo actuators are widely used in:

Machine tool rotary tables

Laser cutting systems

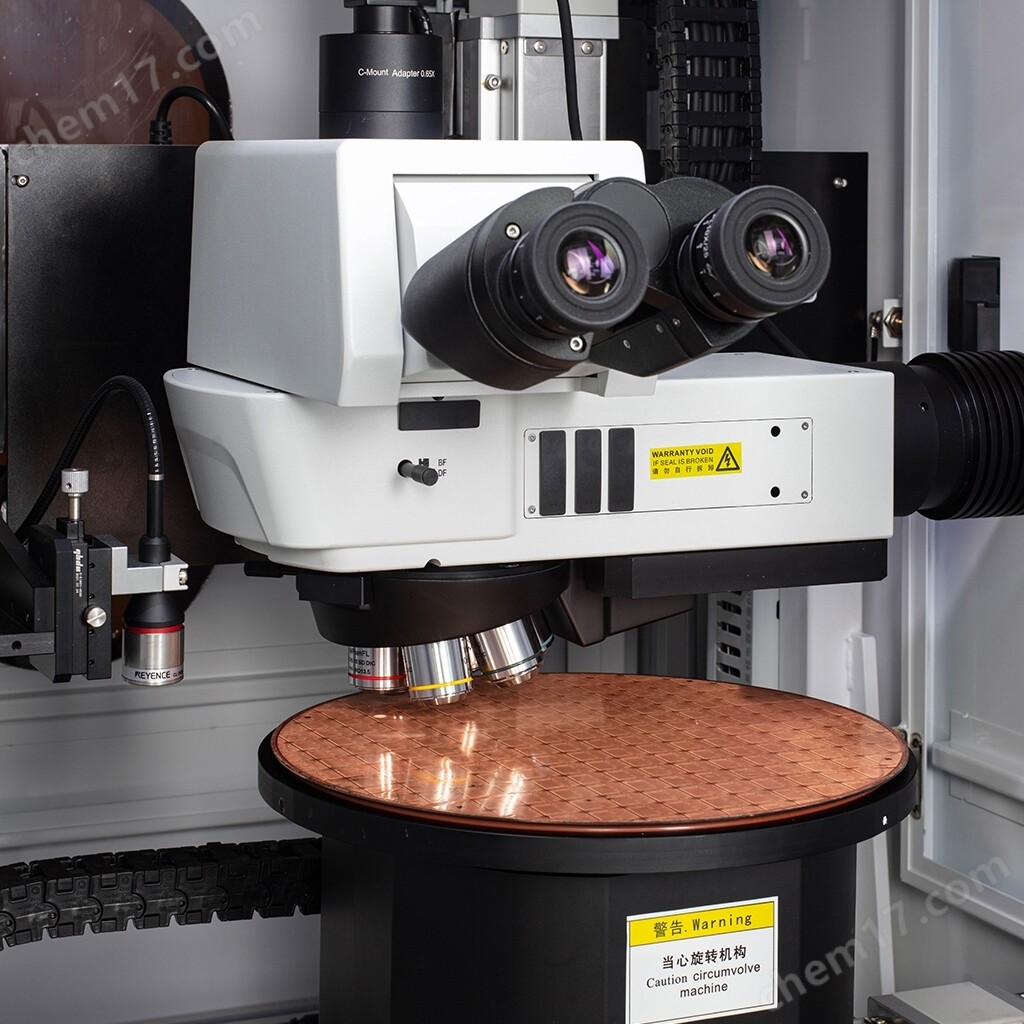

Electronics and semiconductor equipment

Precision CNC machine tools

3C (computer, communication, consumer electronics) equipment

Precision laser processing equipment

LED manufacturing equipment

Inspection and testing equipment

Medical devices

Robots and special robotic arms

Printing machinery and inkjet equipment

Glass processing equipment

Precision measuring instruments

The actuator combines high overturning rigidity, high torque load capacity, and smooth operation, featuring zero backlash and low noise.

With a service life exceeding 15,000 hours, it is maintenance-free and does not require lubricant replacement.

The hollow shaft design allows easy routing of cables and pneumatic lines. It is compatible with standard servo drives and supports plug-and-play installation.

Operating life: 15,000 hours

Operating temperature: −20 °C to +75 °C

The harmonic rotary actuator is equipped with a 23-bit encoder compliant with the Tamagawa protocol.

The motor is designed to work with a 48 V servo drive. Customers may use their own Tamagawa-compatible encoders, or HONPINE can provide an external drive for added convenience.

HONPINE operates two comprehensive test benches rated at 0–100 N·m and 100–1000 N·m, covering the full size range from 11 to 58.

High-precision power analyzers accurately measure current, torque, efficiency, and other parameters, automatically generating performance curves and torque-speed (T-n) curves.

This ensures all specifications are verified by actual output performance, not theoretical estimates. Additional equipment is used for accuracy and rigidity testing.

To address common industry challenges, HONPINE has introduced the upgraded HAT-G series rotary actuator.

While conventional models may deform and rebound under load, the HAT-G series uses advanced proprietary control algorithms to achieve over three times higher rigidity. Under identical loading conditions, dial indicator deflection is almost negligible.

An optional high-precision encoder is available, enabling positioning accuracy of ≤5 arc-seconds.

HONPINE uses high-precision power analyzers to accurately measure current, torque, efficiency, and other key parameters, automatically generating data curves and torque-speed (T-n) curves.

All performance data is validated through real output testing, supported by additional accuracy and rigidity measurement equipment, ensuring reliable and truthful specifications.

Industry Trends

- 00

0000-00

OMG Ultra Compact Harmonic Drive Joint Module with Built-in Torque Sensor![OMG Ultra Compact Harmonic Drive Joint Module with Built-in Torque Sensor OMG Ultra Compact Harmonic Drive Joint Module with Built-in Torque Sensor]()

- 00

0000-00

The Role of Harmonic Drive Gears in Achieving 5–10 μm Accuracy in Dental Milling Machines![The Role of Harmonic Drive Gears in Achieving 5–10 μm Accuracy in Dental Milling Machines The Role of Harmonic Drive Gears in Achieving 5–10 μm Accuracy in Dental Milling Machines]()

- 00

0000-00

Why Harmonic Drive Strain Wave Reducers Are Ideal for Flexographic Printing Machine Registration Systems?![Why Harmonic Drive Strain Wave Reducers Are Ideal for Flexographic Printing Machine Registration Systems? Why Harmonic Drive Strain Wave Reducers Are Ideal for Flexographic Printing Machine Registration Systems?]()

- 00

0000-00

Why Are Harmonic Rotary Actuators Perfect for Medical Equipment?![Why Are Harmonic Rotary Actuators Perfect for Medical Equipment? Why Are Harmonic Rotary Actuators Perfect for Medical Equipment?]()

- 00

0000-00

Harmonic Drive Gearbox – Complete Introduction and Analysis![Harmonic Drive Gearbox – Complete Introduction and Analysis Harmonic Drive Gearbox – Complete Introduction and Analysis]()