Precision Harmonic Drive Reducer / Strain Wave Gear box China Manufacturer

The academic term for harmonic drive is strain wave gearing; based on its physical characteristics, it can also be called a harmonic reducer or harmonic gear. The harmonic drive principle was invented by the outstanding American inventor C.W. Musser and was put into practical application in Japan in 1964. HONPINE company started producing harmonic reducers in 2018 and has continuously optimized the tooth profile. At the end of the 20th century, China began researching the relevant theories and engaging in industrial production. The most significant feature of the harmonic reducer is that it consists of only three basic components: a rigid gear, a flexible gear, and a wave generator. This makes it easy to achieve miniaturization and lightweight design. Due to the large number of teeth involved in the meshing process, it can achieve significant torque transmission and precise control. Currently, there are more than 20 types of harmonic reducers, with a torque range from 1 Nm to 2000 Nm.

Standard Harmonic Drive Reducer

Standard harmonic reduction gear are the most commonly used and widely applied category among all types of harmonic reduction gear. Standard products are mass-produced and sold, resulting in controllable overall costs and stable precision. This major category includes the FSG series, FHG series, FHD series, FSD series, and FDS series.

![Sealed Flange Structure Input Shaft Harmonic Drive Sealed Flange Structure Input Shaft Harmonic Drive]() Sealed Flange Structure Input Shaft Harmonic DriveThe FHG-IV series harmonic drive features an input shaft configuration. It adopts an integrated sealed flange structure that combines harmonic drive components into a single unit, internally filled with specialized lubricating grease for simplified equipment integration. A high-rigidity cross roller bearing (main bearing) is integrated within the assembly. It is typically configured with either fixed circular spline and flexspline output or fixed flexspline and circular spline output.Details

Sealed Flange Structure Input Shaft Harmonic DriveThe FHG-IV series harmonic drive features an input shaft configuration. It adopts an integrated sealed flange structure that combines harmonic drive components into a single unit, internally filled with specialized lubricating grease for simplified equipment integration. A high-rigidity cross roller bearing (main bearing) is integrated within the assembly. It is typically configured with either fixed circular spline and flexspline output or fixed flexspline and circular spline output.Details![Easy Installation Large Hollow Shaft Structure Harmonic Drive Easy Installation Large Hollow Shaft Structure Harmonic Drive]() Easy Installation Large Hollow Shaft Structure Harmonic DriveThe FHG-III series harmonic drive features a large hollow shaft structure. It adopts an integrated sealed flange design that combines harmonic drive components into a single unit, pre-filled with specialized lubricating grease for simplified equipment assembly. A high-rigidity cross roller bearing (main bearing) is integrated internally. This system is typically configured with either fixed circular spline and flexspline output or fixed flexspline and circular spline output.Details

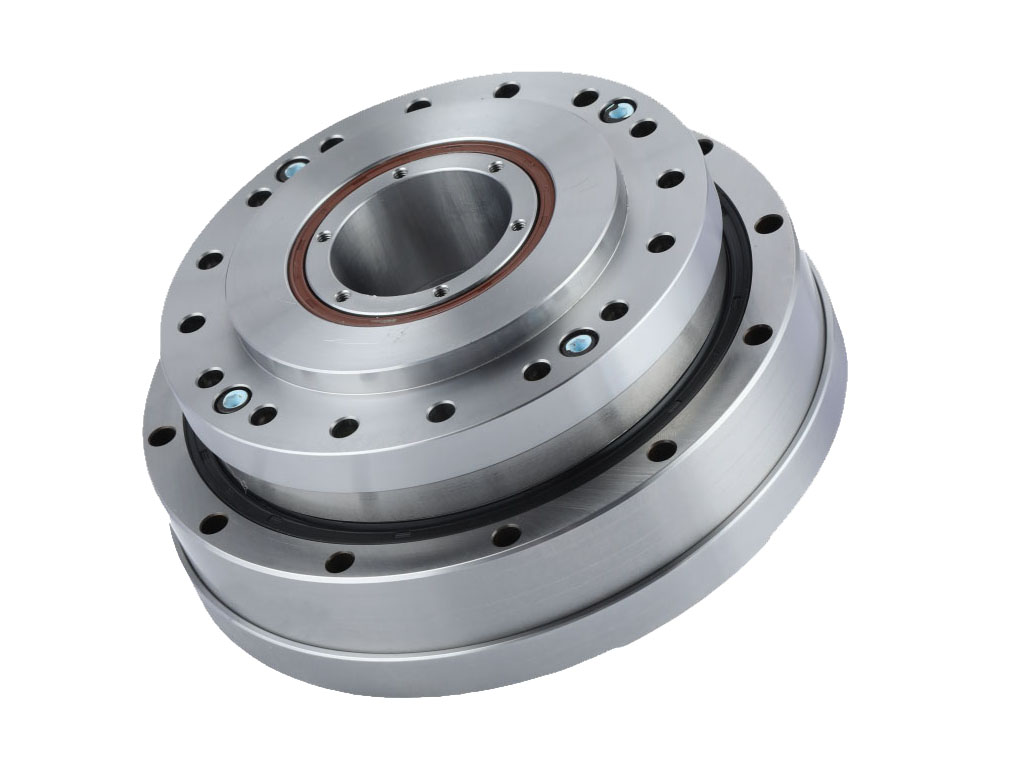

Easy Installation Large Hollow Shaft Structure Harmonic DriveThe FHG-III series harmonic drive features a large hollow shaft structure. It adopts an integrated sealed flange design that combines harmonic drive components into a single unit, pre-filled with specialized lubricating grease for simplified equipment assembly. A high-rigidity cross roller bearing (main bearing) is integrated internally. This system is typically configured with either fixed circular spline and flexspline output or fixed flexspline and circular spline output.Details![High Rigidity High torque High Precision Strain Wave Drive High Rigidity High torque High Precision Strain Wave Drive]() High Rigidity High torque High Precision Strain Wave DriveThe FHG-II series strain wave drive features a cross roller bearing coupling structure for its wave generator, allowing for automatic fine-tuning of coaxiality. The size of the cam shaft hole can be adjusted according to the customer's motor model, with the input shaft directly fitting into the inner bore of the wave generator and connected via a flat key. It incorporates a built-in high-rigidity cross roller bearing (main bearing). Generally, it is used with the rigid wheel end fixed and the flexspline end output, or with the flexspline fixed and the rigid wheel end output as the connection method.Details

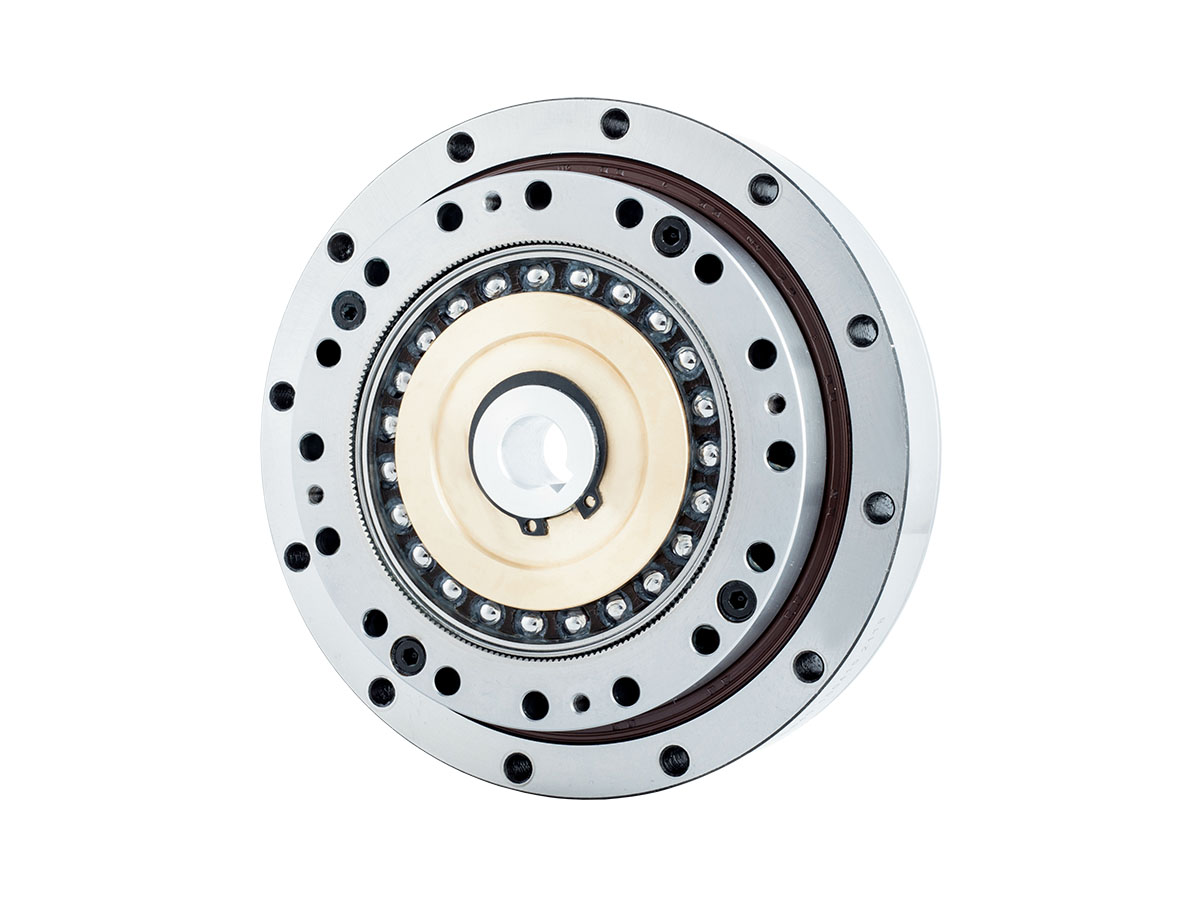

High Rigidity High torque High Precision Strain Wave DriveThe FHG-II series strain wave drive features a cross roller bearing coupling structure for its wave generator, allowing for automatic fine-tuning of coaxiality. The size of the cam shaft hole can be adjusted according to the customer's motor model, with the input shaft directly fitting into the inner bore of the wave generator and connected via a flat key. It incorporates a built-in high-rigidity cross roller bearing (main bearing). Generally, it is used with the rigid wheel end fixed and the flexspline end output, or with the flexspline fixed and the rigid wheel end output as the connection method.Details![Coaxial Input and Output Strain Wave Gear Box Coaxial Input and Output Strain Wave Gear Box]() Coaxial Input and Output Strain Wave Gear BoxThe FHG-I series strain wave gear box features an integrated cam structure for its wave generator. The size of the cam shaft hole can be adjusted according to the customer's motor model, with the input shaft directly fitting into the inner bore of the wave generator and connected via a flat key. It incorporates a built-in high-rigidity cross roller bearing (main bearing). Generally, it is used with the rigid wheel end fixed and the flexspline end output, or with the flexspline fixed and the rigid wheel end output as the connection method.Details

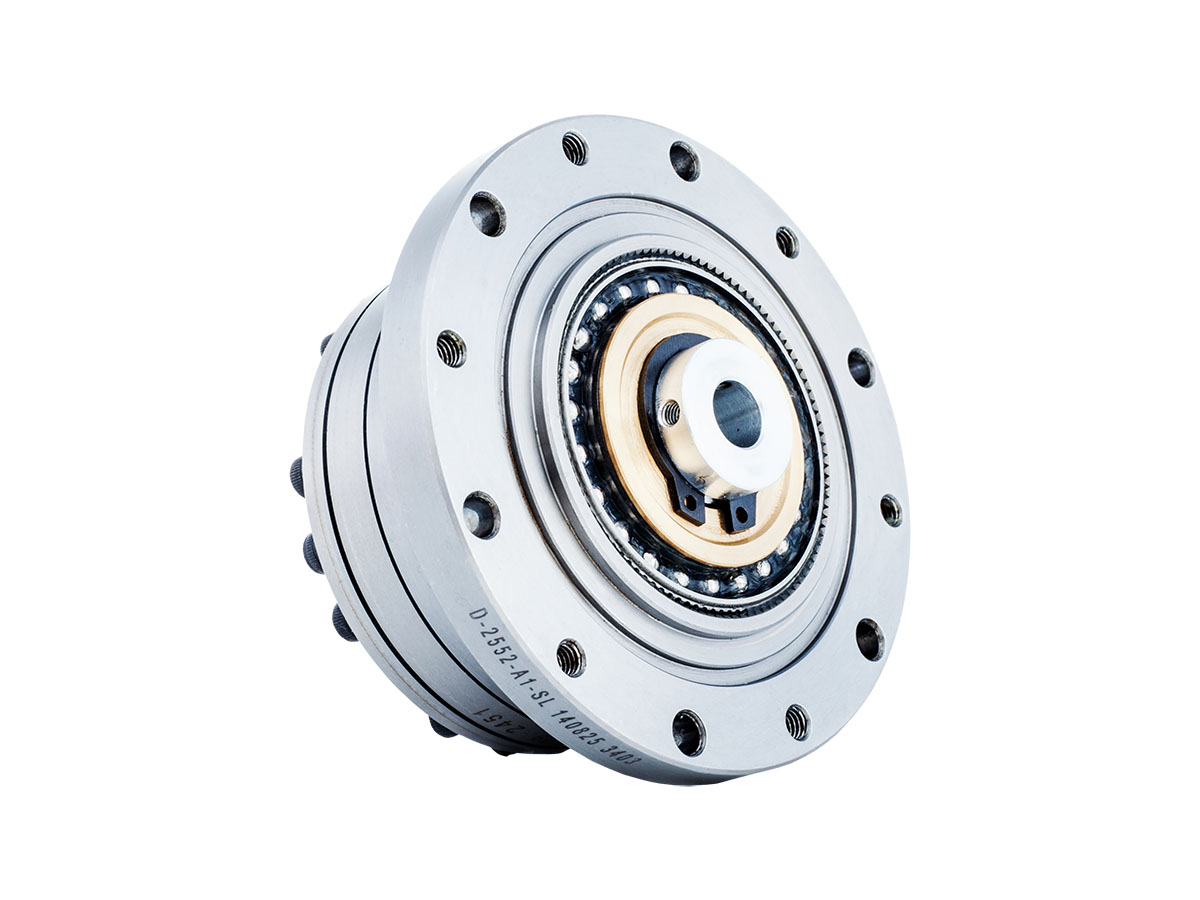

Coaxial Input and Output Strain Wave Gear BoxThe FHG-I series strain wave gear box features an integrated cam structure for its wave generator. The size of the cam shaft hole can be adjusted according to the customer's motor model, with the input shaft directly fitting into the inner bore of the wave generator and connected via a flat key. It incorporates a built-in high-rigidity cross roller bearing (main bearing). Generally, it is used with the rigid wheel end fixed and the flexspline end output, or with the flexspline fixed and the rigid wheel end output as the connection method.Details![Easy Installation Strain Wave Gear for Robot Arm and Sealed Rotary Tables Easy Installation Strain Wave Gear for Robot Arm and Sealed Rotary Tables]() Easy Installation Strain Wave Gear for Robot Arm and Sealed Rotary TablesThe FSG-II series strain wave gear utilizes a cross slider coupling mechanism for its wave generator. The cam shaft bore dimensions can be customized to accommodate specific motor models. The input shaft directly engages with the wave generator’s inner bore through a keyed connection. This configuration is typically implemented with the circular spline fixed at the base and the flexspline serving as the output end.Details

Easy Installation Strain Wave Gear for Robot Arm and Sealed Rotary TablesThe FSG-II series strain wave gear utilizes a cross slider coupling mechanism for its wave generator. The cam shaft bore dimensions can be customized to accommodate specific motor models. The input shaft directly engages with the wave generator’s inner bore through a keyed connection. This configuration is typically implemented with the circular spline fixed at the base and the flexspline serving as the output end.Details![Easy Installation Strain Wave Gear Support Custom Design to Match Motor Models Easy Installation Strain Wave Gear Support Custom Design to Match Motor Models]() Easy Installation Strain Wave Gear Support Custom Design to Match Motor ModelsThe FSG-I series Strain wave gear employs an integrated cam-type wave generator. The cam shaft bore dimensions can be customized to match customer-specific motor models. The input shaft directly interfaces with the wave generator's inner bore via a keyed connection. This system is typically configured with the circular spline fixed at the base and the flexspline functioning as the output end.Details

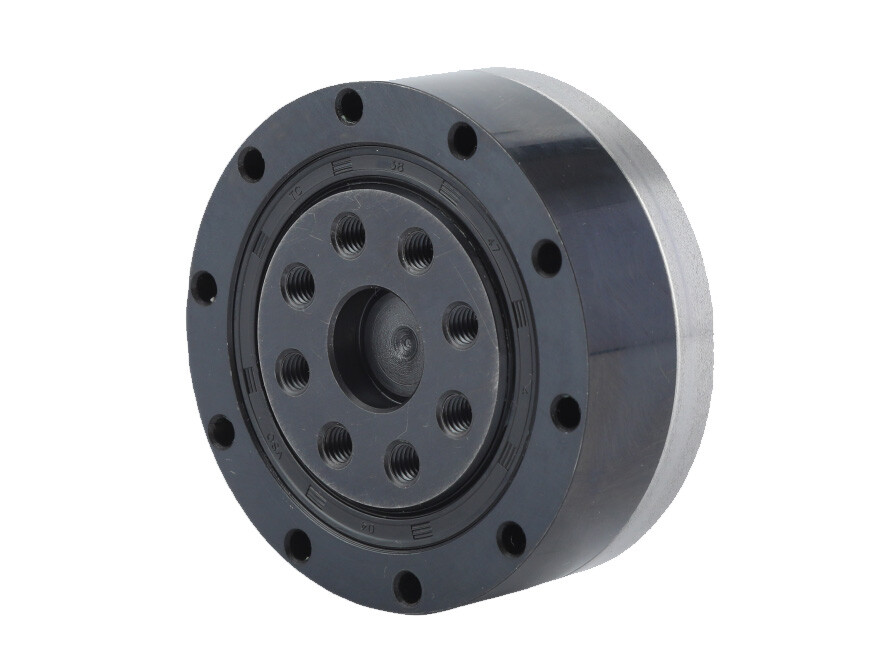

Easy Installation Strain Wave Gear Support Custom Design to Match Motor ModelsThe FSG-I series Strain wave gear employs an integrated cam-type wave generator. The cam shaft bore dimensions can be customized to match customer-specific motor models. The input shaft directly interfaces with the wave generator's inner bore via a keyed connection. This system is typically configured with the circular spline fixed at the base and the flexspline functioning as the output end.Details![Ultra Thin Compact Design Hat Shape Light Weight Harmonic Reducer Ultra Thin Compact Design Hat Shape Light Weight Harmonic Reducer]() Ultra Thin Compact Design Hat Shape Light Weight Harmonic ReducerThe FHD Series harmonic reducer employs an ultra-short top-hat flexspline design, designed for applications demanding extreme compactness and lightweight performance.The FHD Combined Type pursues the ultimate flat-profile design. Compared to the FHG series, its axial length is reduced by approximately 50%. Equipped with high-rigidity cross roller bearings on the output side, it is ideally suited for applications requiring space-constrained designs.Details

Ultra Thin Compact Design Hat Shape Light Weight Harmonic ReducerThe FHD Series harmonic reducer employs an ultra-short top-hat flexspline design, designed for applications demanding extreme compactness and lightweight performance.The FHD Combined Type pursues the ultimate flat-profile design. Compared to the FHG series, its axial length is reduced by approximately 50%. Equipped with high-rigidity cross roller bearings on the output side, it is ideally suited for applications requiring space-constrained designs.Details![Compact Cup Type Harmonic Gear for Aerospace,Robot,LCD Panel,Semiconductor Equipment Compact Cup Type Harmonic Gear for Aerospace,Robot,LCD Panel,Semiconductor Equipment]() Compact Cup Type Harmonic Gear for Aerospace,Robot,LCD Panel,Semiconductor EquipmentThe FSD series harmonic gear adopts an ultra-short cup-type flexspline structural design, achieving approximately 50% shorter axial length compared to the FSG series. It is specifically designed for applications requiring extreme compactness and weight reduction.

Compact Cup Type Harmonic Gear for Aerospace,Robot,LCD Panel,Semiconductor EquipmentThe FSD series harmonic gear adopts an ultra-short cup-type flexspline structural design, achieving approximately 50% shorter axial length compared to the FSG series. It is specifically designed for applications requiring extreme compactness and weight reduction.

In recent years, emerging fields such as humanoid robots, aerospace systems, along with LCD panel and semiconductor manufacturing equipment, have been pursuing ultra-thin solutions under the strict spatial limitations of production line systems.

Building on the lightweight and compact features of harmonic gear transmissions, the FSD series meets market demands by retaining the proven performance of traditional products while implementing bold structural innovations.Details![FDS Ultra Compact Design Harmonic Drive Gear with High Torque FDS Ultra Compact Design Harmonic Drive Gear with High Torque]() FDS Ultra Compact Design Harmonic Drive Gear with High TorqueThe differential gear FDS series is divided into the combined type and the component type. The combined type aims to integrate the differential mechanism into a single unit for easy assembly into equipment, and its housing allows direct mounting of transmission gears, pulleys, etc. The component type pursues a flat and thin design, enabling customers to design their own encapsulation housing and optimize device space according to their structural requirements.

FDS Ultra Compact Design Harmonic Drive Gear with High TorqueThe differential gear FDS series is divided into the combined type and the component type. The combined type aims to integrate the differential mechanism into a single unit for easy assembly into equipment, and its housing allows direct mounting of transmission gears, pulleys, etc. The component type pursues a flat and thin design, enabling customers to design their own encapsulation housing and optimize device space according to their structural requirements.

Utilizing Harmonic Drive's unique operating principle, it is an ultra-compact differential device capable of performing phase and timing fine-tuning during operation.

The combined type of the FDS series shares the same four core components as the pancake component type, except that the combined type includes additional front and rear sealing flanges and support bearings. The FDS series operates on the same working principle as the cup-type FSG series. The shape of the pancake flexspline is identical to the cross-section of the cup flexspline's base, and the wave generator bearings are arranged in two rows, with the tooth width of the circular spline and flexspline increased to handle higher torque capacity. Additionally, the pancake type incorporates an extra circular spline with the same number of teeth as the flexspline for connection to the output shaft.Details

Flange Strain Wave Harmonic Drive

Standard harmonic reduction gear are the most commonly used and widely applied category among all types of harmonic reduction gear. Standard products are mass-produced and sold, resulting in controllable overall costs and stable precision. This major category includes the FSG series, FHG series, FHD series, FSD series, and FDS series.

![High Rigidity Motor Shaft Flange Harmonic Drive Reducer High Rigidity Motor Shaft Flange Harmonic Drive Reducer]() High Rigidity Motor Shaft Flange Harmonic Drive ReducerThe LHSG-RDP series harmonic drive reducer is developed on the high-rigidity FHG-I platform to accommodate customers requiring direct motor integration. It incorporates pre-machined motor shaft connection holes and motor mounting flanges, with the gear unit factory-sealed with specialized lubricating grease. This series typically adopts a fixed flexspline end and an output circular spline end directly coupled to the motor during operation. It offers exceptional convenience for applications demanding both direct motor connection and enhanced harmonic drive rigidity – customers can achieve immediate usability by simply aligning the motor shaft and tightening the fasteners post-purchase. This design optimizes installation efficiency while maintaining structural robustness for high-stiffness direct-drive scenarios.Details

High Rigidity Motor Shaft Flange Harmonic Drive ReducerThe LHSG-RDP series harmonic drive reducer is developed on the high-rigidity FHG-I platform to accommodate customers requiring direct motor integration. It incorporates pre-machined motor shaft connection holes and motor mounting flanges, with the gear unit factory-sealed with specialized lubricating grease. This series typically adopts a fixed flexspline end and an output circular spline end directly coupled to the motor during operation. It offers exceptional convenience for applications demanding both direct motor connection and enhanced harmonic drive rigidity – customers can achieve immediate usability by simply aligning the motor shaft and tightening the fasteners post-purchase. This design optimizes installation efficiency while maintaining structural robustness for high-stiffness direct-drive scenarios.Details![Direct Motor Connection Flange Harmonic Reduction Gear Direct Motor Connection Flange Harmonic Reduction Gear]() Direct Motor Connection Flange Harmonic Reduction GearThe LCSG-RDB harmonic reduction gear series is designed based on the FSG-I platform to facilitate direct motor connection for customers. It features pre-designed motor shaft connection holes and motor mounting flanges, with the gear reducer internally sealed with special lubricating grease at the factory. This series typically employs a fixed circular spline end and an output flexspline end directly coupled to the motor during operation. It provides exceptional convenience for applications requiring direct motor connection and custom sealing flanges - customers can simply secure the motor connection with screws for immediate use after procurement. This design streamlines integration while maintaining sealing integrity for users with direct-drive requirements.Details

Direct Motor Connection Flange Harmonic Reduction GearThe LCSG-RDB harmonic reduction gear series is designed based on the FSG-I platform to facilitate direct motor connection for customers. It features pre-designed motor shaft connection holes and motor mounting flanges, with the gear reducer internally sealed with special lubricating grease at the factory. This series typically employs a fixed circular spline end and an output flexspline end directly coupled to the motor during operation. It provides exceptional convenience for applications requiring direct motor connection and custom sealing flanges - customers can simply secure the motor connection with screws for immediate use after procurement. This design streamlines integration while maintaining sealing integrity for users with direct-drive requirements.Details

Large Harmonic Drive Gearbox

Extra-Large Harmonic drives are designed and manufactured for customers with special torque and size requirements in the harmonic reducer series. These harmonic reducers offer greater torque, higher rigidity, and stronger load capacity. This series includes:

High-torque cup-style flexspline models: FCG-45-AJ, FCG-50-AJ, FCG-58-AJ, FCG-65-AJ;

High-torque top-hat flexspline models: FHG-45-SJ, FHG-50-SJ, FHG-58-SJ, FHG-65-SJ;

High-torque top-hat flexspline models with large hollow sealed structures: FHG-45-AH, FHG-50-AH, FHG-58-AH, FHG-65-AH.

![Compact Design High Torque Heavy Load Strain Wave Gearbox Compact Design High Torque Heavy Load Strain Wave Gearbox]() Compact Design High Torque Heavy Load Strain Wave GearboxThe FHG-SJ series strain wave gearbox is engineered for high-torque and heavy-load applications, featuring compact axial dimensions compared to conventional reducers. It incorporates a top-hat style flexspline and an integrated cam wave generator, where the cam shaft bore is customizable to match specific motor models. The input shaft directly interfaces with the wave generator’s inner bore via a keyway connection. This series typically employs a fixed flexspline end and an output circular spline end configuration.Details

Compact Design High Torque Heavy Load Strain Wave GearboxThe FHG-SJ series strain wave gearbox is engineered for high-torque and heavy-load applications, featuring compact axial dimensions compared to conventional reducers. It incorporates a top-hat style flexspline and an integrated cam wave generator, where the cam shaft bore is customizable to match specific motor models. The input shaft directly interfaces with the wave generator’s inner bore via a keyway connection. This series typically employs a fixed flexspline end and an output circular spline end configuration.Details![High Torque Hat Style Large Hollow Shaft Harmonic Reduction Gear High Torque Hat Style Large Hollow Shaft Harmonic Reduction Gear]() High Torque Hat Style Large Hollow Shaft Harmonic Reduction GearThe FHG-AH series harmonic reduction gear is engineered for high-torque, large hollow shaft, and heavy-load applications. Featuring a top-hat style flexspline and a wave generator cam with an oversized hollow shaft structure, this series enables effortless routing of cables, lead screws, and optical pathways through its central cavity, effectively addressing challenges associated with passing large components. It delivers an optimized solution for such requirements. The series typically employs synchronous pulley connections or large hollow shaft gear structures for input integration.Details

High Torque Hat Style Large Hollow Shaft Harmonic Reduction GearThe FHG-AH series harmonic reduction gear is engineered for high-torque, large hollow shaft, and heavy-load applications. Featuring a top-hat style flexspline and a wave generator cam with an oversized hollow shaft structure, this series enables effortless routing of cables, lead screws, and optical pathways through its central cavity, effectively addressing challenges associated with passing large components. It delivers an optimized solution for such requirements. The series typically employs synchronous pulley connections or large hollow shaft gear structures for input integration.Details![High Torque Heavy Load Cup Style Strain Wave Gear High Torque Heavy Load Cup Style Strain Wave Gear]() High Torque Heavy Load Cup Style Strain Wave GearThe FCG-AJ series strain wave gear is engineered for high-torque and heavy-load applications. It adopts a cup-style flexspline and an integrated cam wave generator, where the cam shaft bore can be customized to match specific motor models. The input shaft directly interfaces with the wave generator's inner bore via a keyway connection. This series typically employs a fixed circular spline end and an output flexspline end configuration.Details

High Torque Heavy Load Cup Style Strain Wave GearThe FCG-AJ series strain wave gear is engineered for high-torque and heavy-load applications. It adopts a cup-style flexspline and an integrated cam wave generator, where the cam shaft bore can be customized to match specific motor models. The input shaft directly interfaces with the wave generator's inner bore via a keyway connection. This series typically employs a fixed circular spline end and an output flexspline end configuration.Details

Mini Harmonic Drive Gear

The micro harmonic drive series is designed and manufactured for customers with special requirements for compact size and lightweight in the harmonic drive reducer family. These reducers feature smaller dimensions, lighter weight, and high precision. This series includes the CSF-mini series with cup-style flexspline structures and the SHD-mini series with top-hat flexspline structures. The CSF-mini series offers multiple input/output configurations, such as shaft input, bore input, shaft output, and flange output. Currently, these products are mass-produced and sold with stable and reliable precision.

![Top Hat Style Compact Axial Dimensions Small Harmonic Drive Top Hat Style Compact Axial Dimensions Small Harmonic Drive]() Top Hat Style Compact Axial Dimensions Small Harmonic DriveThe SHD-mini series harmonic drive is designed for applications with small volume and weight requirements, featuring compact axial dimensions and a top-hat style flexspline. This series exclusively supplies pre-assembled modular products for immediate use. The main bearing employs compact four-point contact ball bearings to directly support external loads. The shaft bore dimensions in this series can be customized to match specific motor shaft sizes. Select the most suitable motor model based on your mechanical design requirements.Details

Top Hat Style Compact Axial Dimensions Small Harmonic DriveThe SHD-mini series harmonic drive is designed for applications with small volume and weight requirements, featuring compact axial dimensions and a top-hat style flexspline. This series exclusively supplies pre-assembled modular products for immediate use. The main bearing employs compact four-point contact ball bearings to directly support external loads. The shaft bore dimensions in this series can be customized to match specific motor shaft sizes. Select the most suitable motor model based on your mechanical design requirements.Details![Cup Stype Compact Design Lightweight Miniature Harmonic drive Cup Stype Compact Design Lightweight Miniature Harmonic drive]() Cup Stype Compact Design Lightweight Miniature Harmonic driveThe CSF-mini series miniature harmonic drive is developed for applications with specialized volume and weight requirements, utilizing a cup-style flexspline. This series exclusively offers pre-assembled modular products for immediate use. The main bearing employs compact four-point contact ball bearings to directly support external loads. The CSF-mini series includes two types: the motor-mount type (2XH) and the shaft-input type (1U) that supports input forms such as belts, gears, and couplings. Select the most suitable model based on your mechanical design requirements.Details

Cup Stype Compact Design Lightweight Miniature Harmonic driveThe CSF-mini series miniature harmonic drive is developed for applications with specialized volume and weight requirements, utilizing a cup-style flexspline. This series exclusively offers pre-assembled modular products for immediate use. The main bearing employs compact four-point contact ball bearings to directly support external loads. The CSF-mini series includes two types: the motor-mount type (2XH) and the shaft-input type (1U) that supports input forms such as belts, gears, and couplings. Select the most suitable model based on your mechanical design requirements.Details

Harmonic Gear Reducer FAQ

A harmonic gear consists of three main components: the flexspline, circular spline, and wave generator.

The operating principle is based on the elastic deformation of the flexspline and the misaligned meshing motion of the gears. The wave generator forces the flexspline to deform elliptically, causing the external teeth of the flexspline to engage sequentially with the internal teeth of the circular spline. This continuous differential engagement produces a high reduction ratio.

The gear ratio of a harmonic drive reducer is determined by the tooth count difference (ΔZ) between the flexspline (Zf) and the circular spline (Zg), transmission mode (double-wave or multi-wave), tooth matching rules, and structural design constraints. These ratios are not random but are based on mature engineering standards widely used in the industry.

Double-wave transmission (ΔZ = 2)

This is the most commonly used configuration due to high meshing efficiency, uniform wear, and long flexspline service life.

Core formulas:

Flexspline output (circular spline fixed):

i = Zf / (Zg − Zf) ≈ Zf / ΔZ

(When ΔZ = 2, i ≈ Zf / 2)

Circular spline output (flexspline fixed):

i = Zg / (Zg − Zf) ≈ Zg / ΔZ

(When ΔZ = 2, i ≈ Zg / 2)

Common Tooth Count and Ratio Examples

Ratio Output Mode Tooth Count (Zg / Zf) Calculation

30 Flexspline output 62 / 60 60 ÷ (62 − 60) = 30

50 Flexspline output 102 / 100 100 ÷ (102 − 100) = 50

100 Flexspline output 202 / 200 200 ÷ (202 − 200) = 100

101 Circular spline out

When selecting a harmonic drive reducer, you should first determine the specific application industry and installation position, then define the following parameters:

Required reduction ratio

Input and output speed

Rated torque and peak torque

Accuracy requirements

Installation method

Space constraints

Providing these details helps ensure accurate and reliable selection.

HONPINE currently offers five main categories of harmonic reducers:

Direct drive harmonic reducers

Hollow type harmonic reducers

Input shaft type harmonic reducers

Ultra-thin harmonic reducers

Mini harmonic reducers

With a complete range of models and tooth profiles, HONPINE products can meet the needs of most customers. If standard models cannot meet specific requirements, customization is supported.

Each core component of our harmonic reducers is manufactured in dedicated workshops, making HONPINE one of the most capable manufacturers for harmonic reducer customization.

Pricing is provided on a one-to-one basis according to the specific model and required quantity.

Contact us:

WhatsApp: +86 189 9432 9920

Email: sales@honpine.com

We need to confirm the exact model and quantity based on your application requirements, and then check inventory availability.

Contact us:

WhatsApp: +86 189 9432 9920

Email: sales@honpine.com

If the required harmonic reducer is in stock, shipment can usually be completed within one week.

If there is no stock, the delivery time will be determined based on the specific model, quantity, and HONPINE factory production schedule.

Contact us:

WhatsApp: +86 189 9432 9920

Email: sales@honpine.com

Yes. HONPINE is a professional harmonic drive reducer manufacturer. You are welcome to contact us to schedule a factory visit.

Contact us:

WhatsApp: +86 189 9432 9920

Email: sales@honpine.com