Robot Industrial AGV DC Drive Wheel Motor

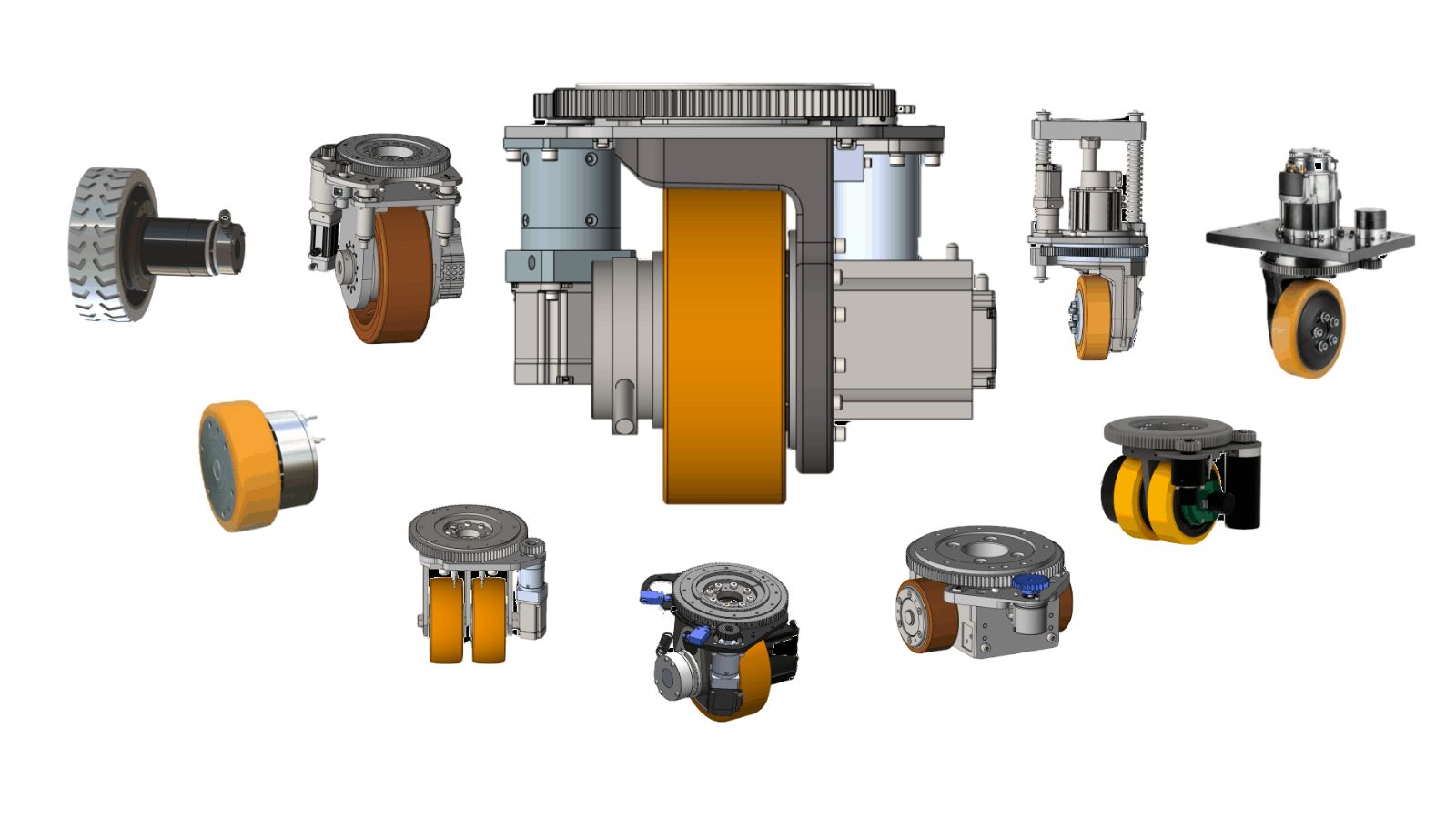

This product line includes both AGV DC wheel motors and industrial drive wheel motors. Due to their ease of installation and the ability of HONPINE to provide solutions tailored to different customer environments, they are widely used in logistics handling, automated sorting, flexible production lines, pharmaceutical transportation, and even high-risk explosion-proof environments.

Robot AGV DC Wheel Servo Motor

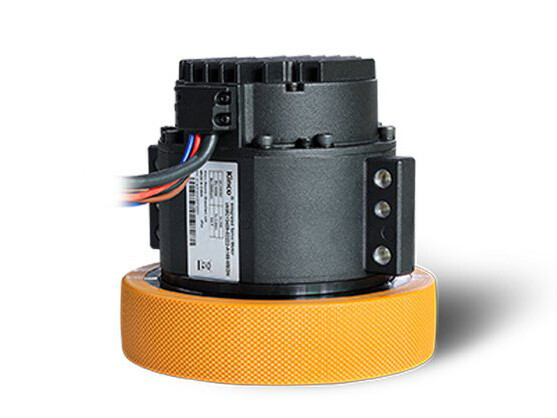

Integrated AGV Robot Servo Wheel Hub MotorThe Integrated Servo Wheel Hub Motor is designed for service robots, warehouse logistics AGVs, and compact medical systems. Featuring a fully integrated drive and hub architecture, it significantly simplifies installation and system design. With an IP67 protection rating, the motor delivers reliable performance even in harsh or demanding environments. It provides high torque output and excellent overload capability, ensuring strong and consistent power for heavy-duty tasks, slopes, and continuous operation. Its smooth low-speed performance and precise control make it an ideal propulsion solution for robots performing cleaning, disinfection, inspection, delivery, and guiding applications.Details

Integrated AGV Robot Servo Wheel Hub MotorThe Integrated Servo Wheel Hub Motor is designed for service robots, warehouse logistics AGVs, and compact medical systems. Featuring a fully integrated drive and hub architecture, it significantly simplifies installation and system design. With an IP67 protection rating, the motor delivers reliable performance even in harsh or demanding environments. It provides high torque output and excellent overload capability, ensuring strong and consistent power for heavy-duty tasks, slopes, and continuous operation. Its smooth low-speed performance and precise control make it an ideal propulsion solution for robots performing cleaning, disinfection, inspection, delivery, and guiding applications.Details High Efficiency Humanoid Robots Steering Four Wheel Drive ModuleAs application scenarios for general-purpose humanoid robots (including wheeled humanoid robots) continue to expand, higher demands are being placed on the flexibility of robot mobility. Traditional differential-drive robot chassis cannot achieve lateral movement in place, suffer from limitations in turning radius, and operate with lower efficiency due to the lack of omnidirectional motion capabilities.

High Efficiency Humanoid Robots Steering Four Wheel Drive ModuleAs application scenarios for general-purpose humanoid robots (including wheeled humanoid robots) continue to expand, higher demands are being placed on the flexibility of robot mobility. Traditional differential-drive robot chassis cannot achieve lateral movement in place, suffer from limitations in turning radius, and operate with lower efficiency due to the lack of omnidirectional motion capabilities.

To address these challenges, HONPINE has launched the iGMH and iGML series steering-wheel drive and steering modules. These modules highly integrate core components—including the servo driver, servo motor, encoder, and wheel—greatly improving space utilization within the robot chassis.Details AGV AMR Hub Servo Wheel MotorThe AGV wheel motor (also known as Hub Servo Motor) is a highly integrated electromechanical drive system that combines core components, including planetary gear mechanism, servo motor, brake, encoder, drive controller, and wheel assembly into a compact unit. This module adopts a frameless torque motor design to directly drive the wheel motion, replacing the traditional "motor + reducer + wheel" separated solution, and possesses high-precision motion control capabilities.It is primarily applied in AGVs (Automated Guided Vehicles), AMRs (Autonomous Mobile Robots), and industrial automation equipment, meeting the efficient material handling demands in fields such as warehousing logistics and smart manufacturing. Hub motors demonstrate significant advantages in improving equipment efficiency, reducing comprehensive costs, and adapting to complex scenarios.Details

AGV AMR Hub Servo Wheel MotorThe AGV wheel motor (also known as Hub Servo Motor) is a highly integrated electromechanical drive system that combines core components, including planetary gear mechanism, servo motor, brake, encoder, drive controller, and wheel assembly into a compact unit. This module adopts a frameless torque motor design to directly drive the wheel motion, replacing the traditional "motor + reducer + wheel" separated solution, and possesses high-precision motion control capabilities.It is primarily applied in AGVs (Automated Guided Vehicles), AMRs (Autonomous Mobile Robots), and industrial automation equipment, meeting the efficient material handling demands in fields such as warehousing logistics and smart manufacturing. Hub motors demonstrate significant advantages in improving equipment efficiency, reducing comprehensive costs, and adapting to complex scenarios.Details

Industrial Steering Drive Wheel Motor

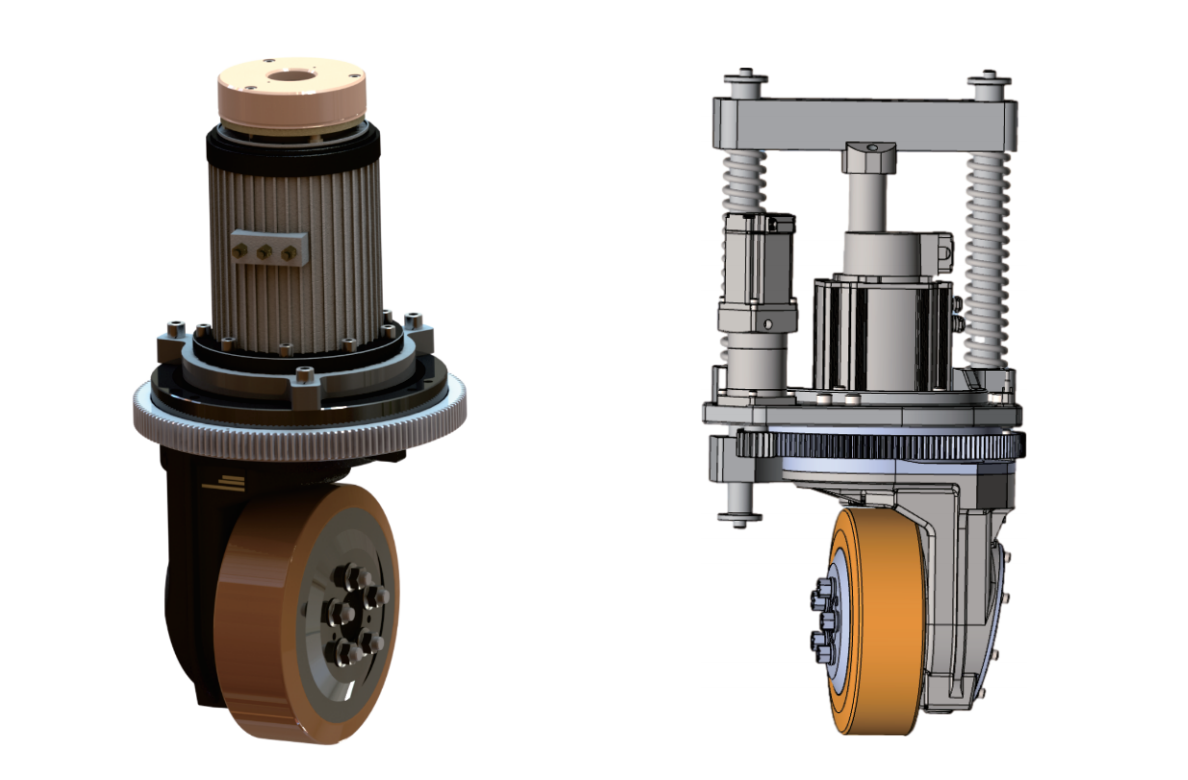

![360° rotation Outdoor Vertical Steering Wheel 360° rotation Outdoor Vertical Steering Wheel]() 360° rotation Outdoor Vertical Steering WheelThe vertical steering wheel is designed for outdoor applications, offering excellent water-crossing capability as well as strong climbing and obstacle-overcoming performance.The term vertical steering wheel refers to a structure in which the motor is mounted vertically above the drive wheel.When integrated with a drive controller, a mobile platform equipped with a single steering wheel can perform start/stop, forward and backward movement, and steering functions.When two or more steering wheels are configured, the system enables zero-radius rotation, lateral movement, omnidirectional 360° rotation, straight travel, sideways motion, diagonal motion, and curved trajectories—allowing free movement in any direction on a two-dimensional plane.Details

360° rotation Outdoor Vertical Steering WheelThe vertical steering wheel is designed for outdoor applications, offering excellent water-crossing capability as well as strong climbing and obstacle-overcoming performance.The term vertical steering wheel refers to a structure in which the motor is mounted vertically above the drive wheel.When integrated with a drive controller, a mobile platform equipped with a single steering wheel can perform start/stop, forward and backward movement, and steering functions.When two or more steering wheels are configured, the system enables zero-radius rotation, lateral movement, omnidirectional 360° rotation, straight travel, sideways motion, diagonal motion, and curved trajectories—allowing free movement in any direction on a two-dimensional plane.Details![Horizontal Drive Mechatronic Wheel Motor Horizontal Drive Mechatronic Wheel Motor]() Horizontal Drive Mechatronic Wheel MotorA horizontal drive wheel is a mechatronic integrated product in which the traction drive motor is horizontally mounted on the drive wheel. It integrates the traction motor with a speed feedback unit, reduction transmission mechanism, braking system, mounting and support structure, and rubber-coated wheel.It features low installation height, high precision, lightweight design, high load capacity, high torque, high speed, reliable performance, long service life, easy installation, and convenient maintenance.Details

Horizontal Drive Mechatronic Wheel MotorA horizontal drive wheel is a mechatronic integrated product in which the traction drive motor is horizontally mounted on the drive wheel. It integrates the traction motor with a speed feedback unit, reduction transmission mechanism, braking system, mounting and support structure, and rubber-coated wheel.It features low installation height, high precision, lightweight design, high load capacity, high torque, high speed, reliable performance, long service life, easy installation, and convenient maintenance.Details![360° Rotating AGV Horizontal Drive Steering Wheel 360° Rotating AGV Horizontal Drive Steering Wheel]() 360° Rotating AGV Horizontal Drive Steering WheelThe AGV horizontal drive steering wheel features an integrated design that combines a steering motor, reduction transmission mechanism, position feedback unit, limit device, and rotary mechanism into a single compact module.

360° Rotating AGV Horizontal Drive Steering WheelThe AGV horizontal drive steering wheel features an integrated design that combines a steering motor, reduction transmission mechanism, position feedback unit, limit device, and rotary mechanism into a single compact module.

When equipped with a drive controller, a mobile platform configured with a single steering wheel can perform start/stop, forward and backward movement, and steering functions.

When two or more steering wheels are used, the system enables zero-radius rotation, lateral movement, omnidirectional 360° rotation, straight-line travel, sideways motion, diagonal movement, and curved trajectories—allowing free movement in any direction on a two-dimensional plane.Details

AGV Steering Robot DC Wheel Motor-FAQ

HONPINE omnidirectional steering wheel modules demonstrate outstanding low-speed stability, effectively reducing vibration, jerks, and hesitation during steering and movement. They deliver powerful output torque, enabling easy adaptation to a wide range of load conditions. As a wear component, the driving wheel can be conveniently replaced, significantly simplifying maintenance.

In addition, the high-rigidity structural design of the module minimizes the impact of external shocks on motion accuracy, providing robots with more reliable and precise motion control performance.

With the rapid growth of the global embodied intelligence market, power components have become a critical foundation for embodied intelligent robots. Their performance directly determines the robot’s application capabilities across various scenarios and has become a key competitive differentiator.

As technological competition around robotic power components intensifies, HONPINE continues to achieve breakthroughs in high power density, low energy consumption, and compact design to meet the complex demands of diversified robotic application scenarios.

HONPINE’s cutting-edge innovation solutions for embodied humanoid robots—featuring advanced technology, outstanding performance, and broad adaptability—are injecting continuous momentum into the rapid development of the global embodied intelligence industry, helping China’s embodied intelligence sector gain a competitive edge on the global stage.

Hub motors with integrated reducers represent not only a product upgrade, but also a paradigm shift toward standardized intelligent modules in drive systems. Competition is evolving from individual component performance to comprehensive capabilities encompassing system integration, scenario understanding, and intelligent control.

This integrated approach aligns seamlessly with the trends of AI and industrial automation, delivering higher efficiency, reliability, and scalability.

AGV hub motors offer multiple outstanding advantages. Their high level of integration consolidates numerous functions into a single unit, reducing the need for external components and resulting in a more compact structure with higher precision.

Built-in encoders and Hall sensors enable precise motor control, while fast response ensures rapid reaction to control signals, significantly improving operational efficiency. Stable low-speed performance guarantees smooth operation even under low-speed conditions.

Limitations of Traditional Robot Chassis Mobility

Differential two-wheel drive limits omnidirectional movement, resulting in slower operation cycles

Chassis height constraints make traditional vertical steering wheels bulky and difficult to install

Chassis must withstand complex environments and external impacts, while upper-mounted robotic arms impose high loads—exceeding the radial load capacity and peak torque limits of conventional hub motors

HONPINE iSWV Series Omnidirectional Steering Wheels: A Complete Solution

High integration, optimized space utilization

Highly integrated and modular design with neatly arranged flexible wiring significantly reduces module size and height, maximizing vehicle space utilization.

Smoother operation, easier maintenance

Improved coaxial alignment between motor and reducer reduces operational noise. Wear-prone driving wheels can be easily replaced, lowering maintenance complexity.

Intelligent and reliable, no data loss

Equipped with a backup power s

HONPINE is one of China’s early high-tech enterprises dedicated to the R&D of core drive systems for AGV wheeled mobile handling robots. With 16 years of experience in R&D, manufacturing, and sales, the company holds over 10 invention patents and has developed multiple world-first and China-first high-tech products.

These include the world’s smallest horizontal steering wheel, the world’s smallest vertical steering wheel, and the world’s first dual-wheel steering system. HONPINE products integrate drive mechanisms and speed feedback, steering mechanisms and position feedback, limit devices, braking systems, and support structures—ensuring comprehensive safety and stability.

HONPINE’s drive wheel systems cover four major series, including horizontal and vertical steering wheels and driving wheels.

Horizontal steering wheels are ideal for electrically driven mobile equipment with height constraints, offering a low mounting surface and high gear ratios.

Vertical steering wheels are better suited for outdoor applications, enabling water wading, superior terrain adaptability, improved obstacle-crossing capability, and enhanced climbing performance.

To meet diverse industry requirements, HONPINE has refined its products through years of development. Horizontal drive wheel series offer reliable performance, easy installation, and convenient maintenance, providing solutions for lightweight design, high load capacity, large torque, and high speed. Vertical steering wheels, meanwhile, excel in outdoor environments with superior passability and obstacle negotiation capabilities.

Yes. HONPINE’s AGV wheels motors are available as standard products or fully customized solutions to meet specific customer requirements. They are widely used in AGVs, electric forklifts, aerial work platforms, cleaning robots, and various mobile robotic systems, making HONPINE a globally recognized provider of electric drive solutions.

HONPINE works closely with AGV industry users to gain in-depth insights into harsh industrial application environments and accurately identify customer pain points. Each product is designed and validated under stringent operating conditions, with extensive use of high-strength materials and advanced heat treatment processes to ensure mechanical durability.

The company is equipped with multiple comprehensive test benches, with testing capabilities reaching 4500 rpm @ 300 Nm, covering drive system design, performance testing, waterproof and dustproof validation, and product verification.

HONPINE’s servo steering wheels incorporate premium industry components and leverage engineers’ extensive experience. After rigorous testing, the resulting products feature small turning radii, compact structures, smooth transmission, and high efficiency.

- 00

0000-00

OMG Ultra Compact Harmonic Drive Joint Module with Built-in Torque Sensor![OMG Ultra Compact Harmonic Drive Joint Module with Built-in Torque Sensor OMG Ultra Compact Harmonic Drive Joint Module with Built-in Torque Sensor]()

- 00

0000-00

Harmonic Drive Gearbox – Complete Introduction and Analysis![Harmonic Drive Gearbox – Complete Introduction and Analysis Harmonic Drive Gearbox – Complete Introduction and Analysis]()

- 00

0000-00

Harmonic Joint Motor VS Planetary Joint Motor![Harmonic Joint Motor VS Planetary Joint Motor Harmonic Joint Motor VS Planetary Joint Motor]()

- 00

0000-00

HONPINE Harmonic Drive’s Backdriveability Enables Technological Breakthroughs in Multiple Fields![HONPINE Harmonic Drive’s Backdriveability Enables Technological Breakthroughs in Multiple Fields HONPINE Harmonic Drive’s Backdriveability Enables Technological Breakthroughs in Multiple Fields]()

- 00

0000-00

Integrated Harmonic Actuators Are Gradually Replacing the Traditional Harmonic Drive Reducer + Servo Motor Solution and It Is Developing Fastly![Integrated Harmonic Actuators Are Gradually Replacing the Traditional Harmonic Drive Reducer + Servo Motor Solution and It Is Developing Fastly Integrated Harmonic Actuators Are Gradually Replacing the Traditional Harmonic Drive Reducer + Servo Motor Solution and It Is Developing Fastly]()