Robot Communication Protocols: Why EtherCAT and CAN Are the Future

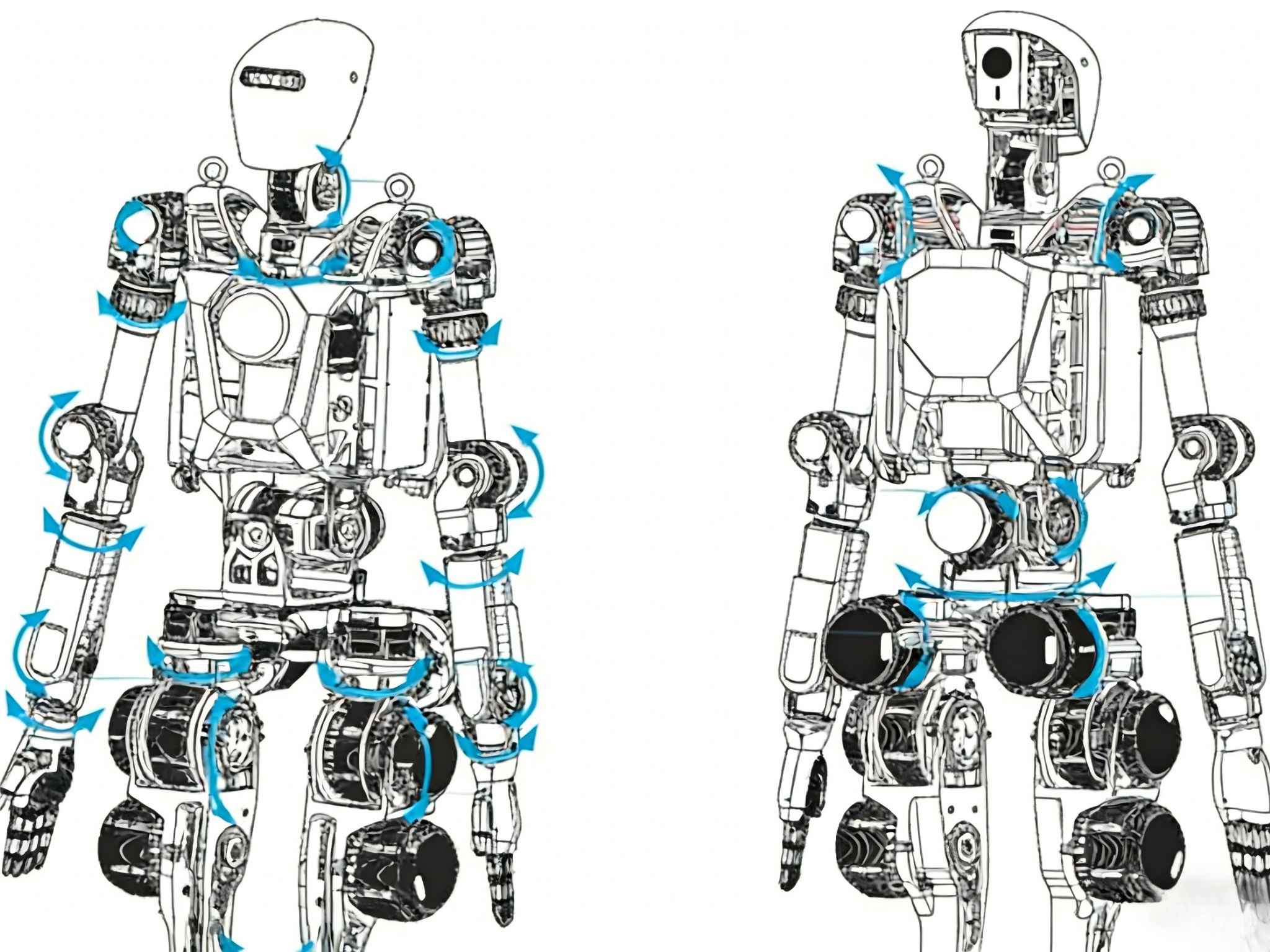

According to statistics released by the EtherCAT Technology Group (ETG) in 2024, EtherCAT has captured 39.2% of the global industrial robot communication protocol market, with an annual growth rate of 12.7%, significantly outperforming other competing protocols. Its advantages are particularly evident in key application scenarios: from multi-joint real-time coordinated control in humanoid robots, to multi-sensor fusion in autonomous driving, and human–machine collaboration in Industry 4.0. EtherCAT is redefining how intelligent systems interact with the physical world.

Why EtherCAT Is Gaining Increasing Attention?

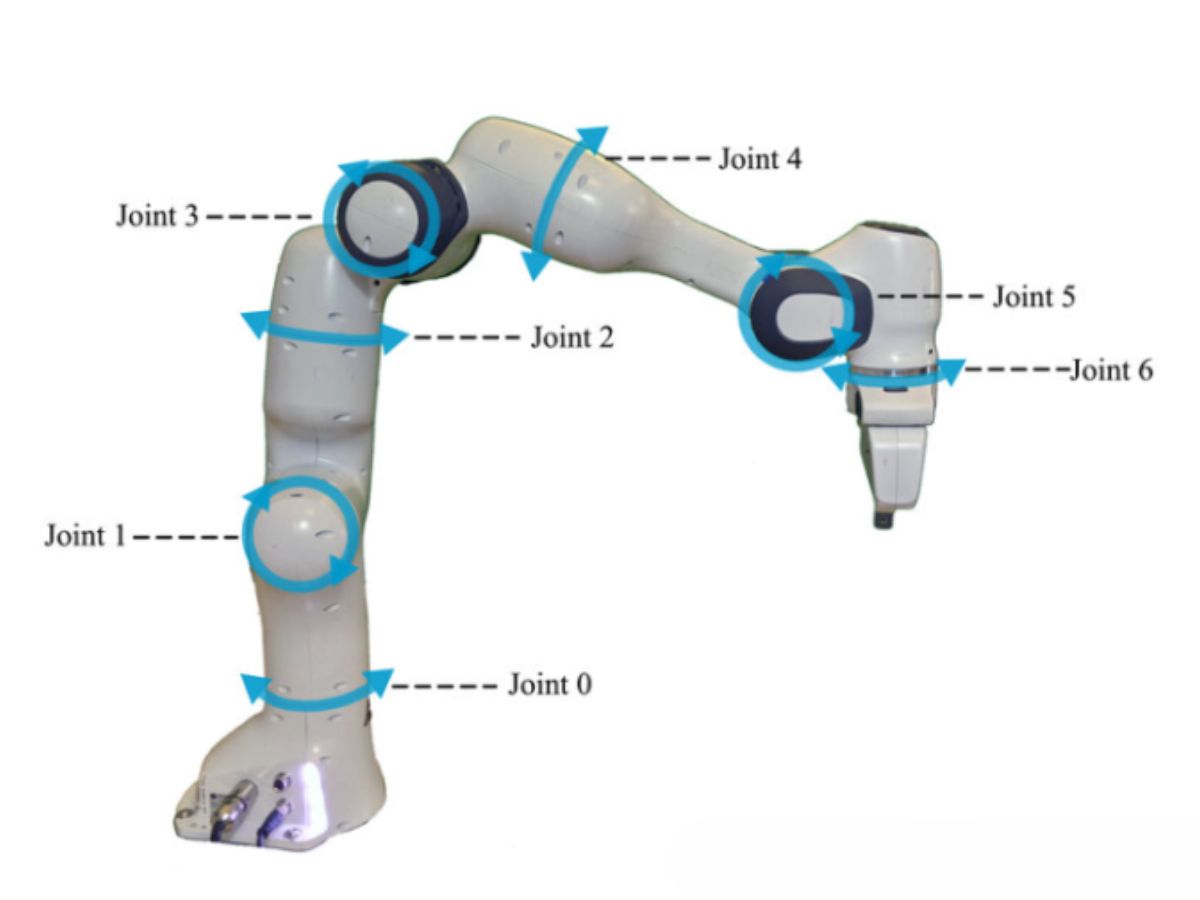

EtherCAT is one of the mainstream communication methods for robot joints, widely used in industrial robots and humanoid robot joint control. Leading robot manufacturers such as KUKA and FANUC extensively adopt EtherCAT as their control bus to support complex tasks including welding, material handling, and spraying.

EtherCAT is particularly well suited for applications with strict real-time requirements. Robot joint control typically involves three nested loops—current, velocity, and position—which require a fast closed-loop process of signal acquisition → computation → output.

EtherCAT also supports a unified full-body communication architecture for robots. In some systems, it is combined with CAN—for example, EtherCAT for the upper body and CAN for the lower body.

EtherCAT (Ethernet for Control Automation Technology) was first introduced in 2003 by Beckhoff Automation (Germany). At the time, the industrial sector urgently needed a high-speed, efficient, and low-cost communication solution. EtherCAT emerged to overcome the limitations of traditional Ethernet in industrial automation and quickly gained widespread attention. One of its most notable features is its extremely high data transmission speed, enabling nanosecond-level synchronization accuracy.

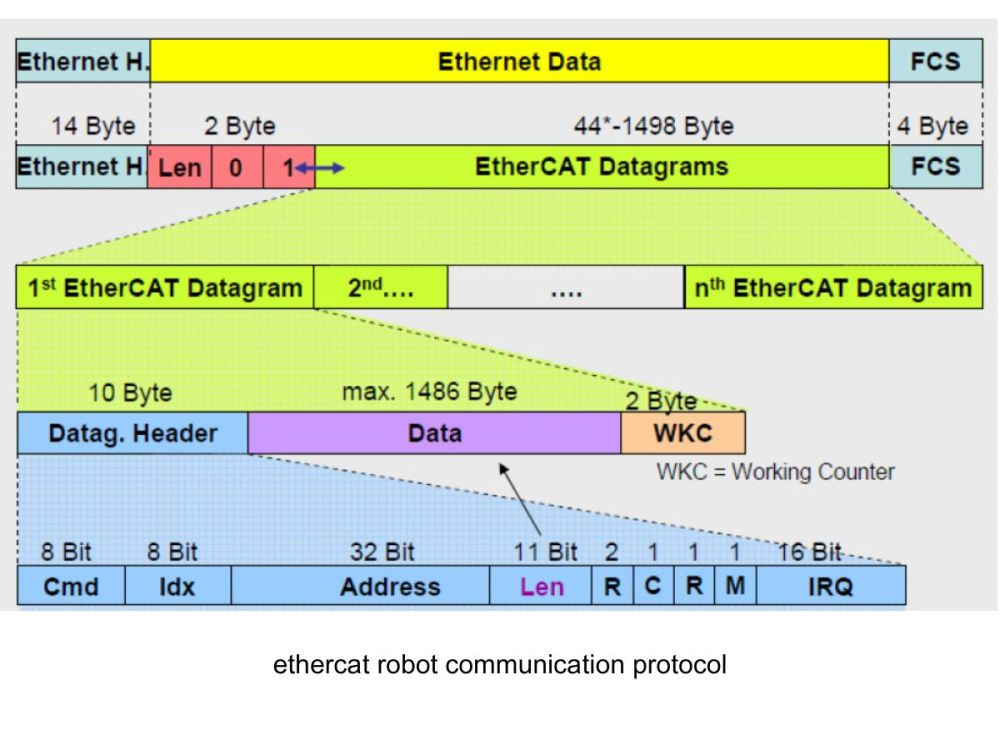

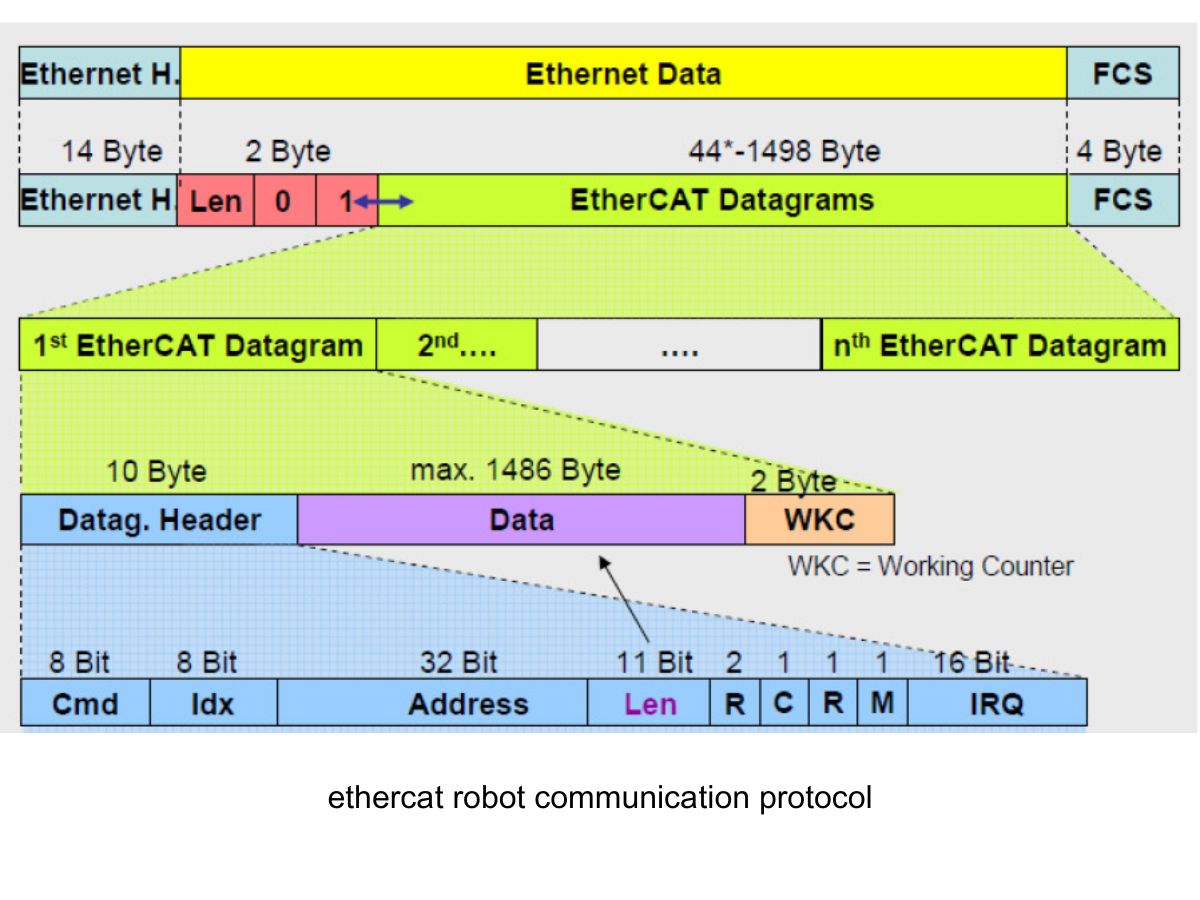

EtherCAT uses only three protocol layers—physical layer, data link layer, and application layer—similar to traditional fieldbuses. However, compared with other real-time Ethernet protocols such as PROFINET and EtherNet/IP, EtherCAT’s protocol stack is far more streamlined. This enables ultra-high-speed data exchange within very short cycles, fully meeting the real-time control requirements of robots and allowing rapid command response and high-precision motion control.

Its Distributed Clock (DC) technology ensures precise synchronization of all devices on the network, allowing robot joints to move in perfect coordination and avoiding motion errors caused by timing deviations.

“Processing on the Fly”: EtherCAT’s Core Competitive Advantage

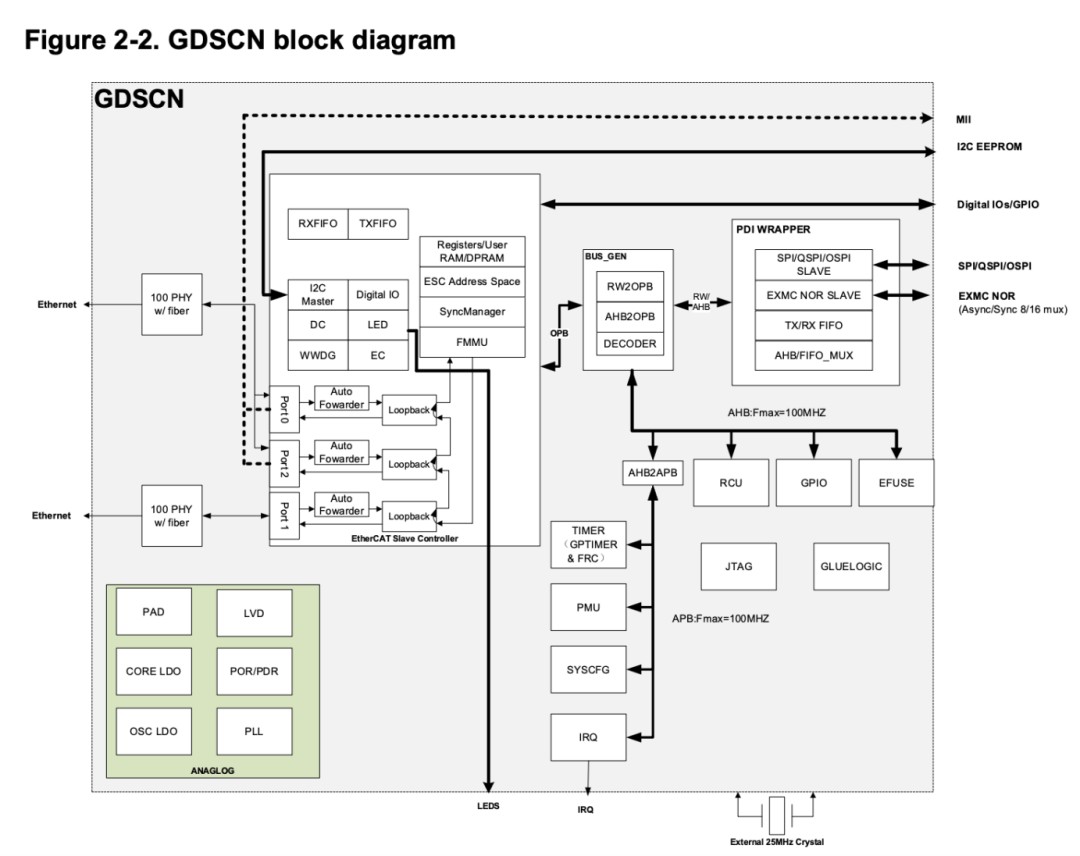

On-the-Fly / Processing on the Fly is often regarded as EtherCAT’s technological moat. Engineers note that this feature is currently unique to EtherCAT and does not rely on IP-based communication. It is the core design that enables EtherCAT’s exceptional performance, allowing slave devices to read or write data directly as frames pass through—without storing the entire frame—achieving microsecond-level real-time communication.

Unlike traditional Ethernet protocols that rely on store-and-forward mechanisms, EtherCAT slaves process data directly during frame transmission. The per-node processing delay is as low as 1 μs. Key technical implementations include:

Distributed clock synchronization: Using master–slave clock offset compensation algorithms, network-wide synchronization accuracy better than 100 ns, compliant with enhanced IEEE 1588 standards.

Optimized frame structure: An ultra-compact 8-byte frame header, achieving up to 98% data payload efficiency (compared to ~60% for PROFINET), significantly improving bandwidth utilization.

From both performance and safety perspectives, EtherCAT is extremely powerful. However, another major reason for its dominance lies in its openness.

From an engineer’s point of view, EtherCAT may not be as easy to use as CAN, but for motion-control-intensive applications, EtherCAT offers the best cost-performance ratio.

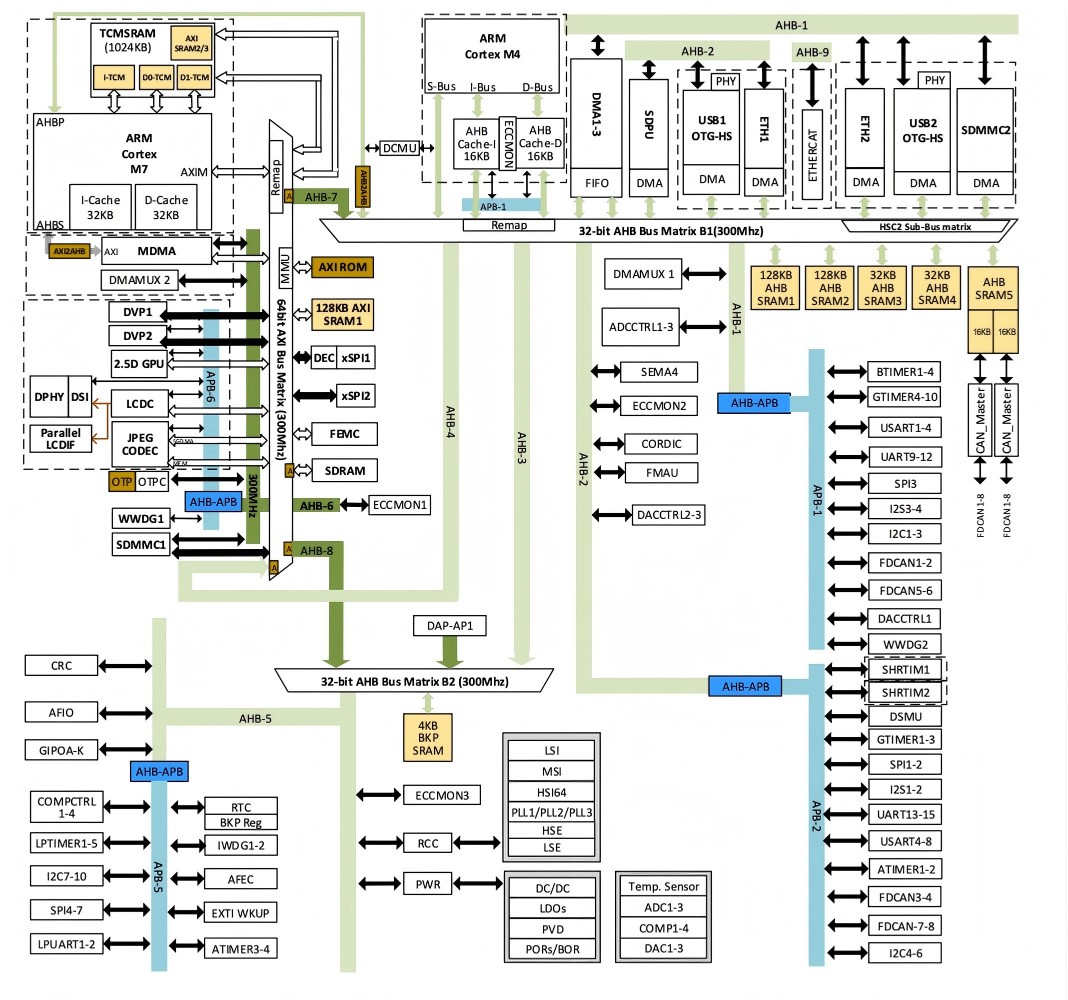

Today, MCU manufacturers place great strategic importance on EtherCAT.

As early as December 2023, HPMicro announced China’s first high-performance MCU series with an officially licensed EtherCAT Slave Controller (ESC) from Beckhoff—the HPM6E00 series—followed by the robot-focused HPM6E8Y. At CES 2026, HPMicro introduced the HPM5E3Y, a high-performance MCU specifically designed for robot joints. It integrates an EtherCAT slave controller and two Ethernet PHY transceivers, features a RISC-V core running at 480 MHz, includes 512 KB RAM and 1 MB Flash, and comes in an ultra-compact package as small as 9 × 9 mm, making it ideal for space-constrained robot joint designs. Together, HPM5E3Y and HPM6E8Y form the world’s most complete robot joint MCU product lineup.

Why Many Customers Still Choose CAN?

CAN (and its motion-control-oriented variant, CANopen) is another mainstream communication solution for robots, particularly suitable for applications with lower real-time requirements, such as robot lower bodies and wheeled robot drives.

As EtherCAT costs decline, some CAN application scenarios have been compressed. However, CAN remains widely used in robots with fewer joints and lower control frequencies, such as quadruped robots and robotic dogs. Moreover, CAN is still indispensable in humanoid robots. For example, Zhiyuan Lingxi X1 uses 100 Mbps EtherCAT at 1 kHz real-time communication, with EtherCAT gateways forwarding data to three CAN FD channels operating at up to 5 Mbps.

CAN supports multi-segment network partitioning. In humanoid robots with over 40 joints, joints can be grouped by limbs (arms, legs) into multiple CAN FD segments, reducing delays and packet loss caused by bus arbitration.

Originally designed for automotive electronics, CAN emphasizes reliability and noise immunity. It employs a Carrier Sense Multiple Access with Non-Destructive Arbitration (CSMA/CA) mechanism, allowing multiple nodes to transmit when the bus is idle. In the event of a collision, higher-priority messages (lower ID values) continue transmission, while lower-priority messages automatically back off—ensuring lossless arbitration.

This mechanism enables distributed decision-making and high reliability, making CAN ideal for transmitting switch signals and sensor data. Consequently, it is widely used in communication among automotive electronic control units (ECUs). However, when applied to multi-axis coordinated motion control with extremely high real-time and periodic requirements, CAN’s inherent limitations become apparent.

From a system selection perspective, CAN is often used to extend existing CAN-based architectures. For systems with fewer axes (e.g., fewer than six) and less stringent synchronization and dynamic performance requirements—such as desktop robots and AGVs—CAN is sufficient, economical, and well-known for its robustness in harsh environments. EtherCAT, on the other hand, is better suited for high-performance or large-scale distributed robotic systems. Although the per-node cost may be higher, EtherCAT’s advantages in simplified wiring, elimination of repeaters, ease of debugging and maintenance, and overall performance improvement often result in a lower total cost of ownership over the long term.

The Rapid Development of the I3C Protocol

I3C is an emerging sensor communication protocol, with many companies actively promoting its use in robotic dexterous hands. It eliminates the need for external PHYs, simplifying hardware design. For example:

NXP i.MX RT1180 integrates two I3C interfaces, enabling connections to multiple servo nodes and sensors.

Infineon PSoC Edge supports I3C.

Renesas RA8 high-performance MCU series supports I3C

Microchip PIC18-Q20 series includes high-speed I3C modules.

STMicroelectronics STM32N6, STM32H5, STM32H7, and STM32U3 all support I3C.

I3C is well suited for multi-motor control in dexterous hands and high-density sensor data acquisition (such as electronic skin and torque sensors), especially in space-constrained environments like robot fingers.

At present, CAN FD remains the mainstream solution for dexterous hands. Due to ecosystem immaturity, I3C has not yet been widely adopted. Some engineers also believe that I3C offers weaker noise immunity, making large-scale deployment in dexterous hands challenging.

Nevertheless, technology continues to evolve. Some domestic chip manufacturers are incorporating I3C into their R&D roadmaps and will advance mass production based on market demand, while also keeping a close eye on emerging protocols such as CAN XL. As a result, the communication protocol landscape is likely to undergo further transformation in the future.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand