Why are harmonic robot joint actuators and planetary robot joint actuators the ideal choices for the upper and lower limbs of humanoid robots, respectively?

The selection of robot joint actuators for humanoid robots is essentially a precise matching of functional requirements, performance trade-offs, and cost control. Among today’s mainstream solutions, harmonic joint actuators are typically prioritized for upper limbs, while planetary joint actuators are favored for lower limbs. This combination is not accidental, but rather the optimal solution derived from the distinct motion characteristics of the upper and lower body. The differentiated approaches taken by companies such as Unitree and UBTECH also stem from specific considerations tied to their product positioning.

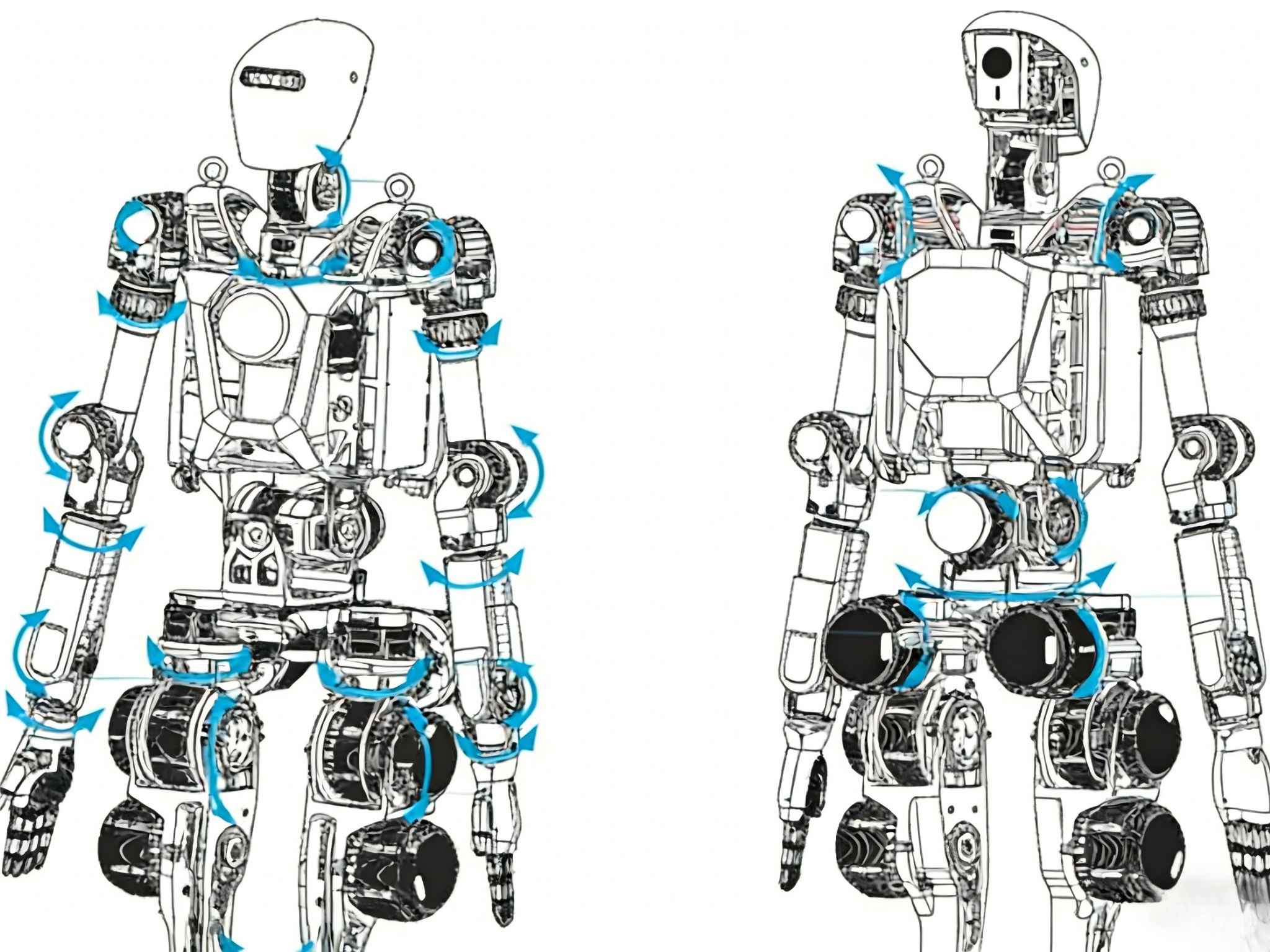

Upper-Limb Joints: Precision and Dexterity as the Core Requirements

The primary demand for upper-limb joints is dexterity and high precision, which harmonic actuators are particularly well suited to deliver. Harmonic actuators use a wave generator to drive elastic deformation of the flexspline for meshing transmission, enabling ultra-high positioning accuracy of less than 1 arcminute. Their near-zero backlash allows robots to perform delicate operations such as grasping small objects and executing precision assembly tasks.

In addition, harmonic actuators feature an extremely compact and lightweight structure. At the same reduction ratio, their volume is significantly smaller than that of planetary modules, effectively reducing upper-limb mass and optimizing the overall center-of-gravity distribution of the robot.

Data show that harmonic actuators offer excellent torque density, achieving 57.8 N·m/kg with a weight of only 0.84 kg, making them ideal for space-constrained upper-limb joints such as the shoulder, elbow, and wrist that require high-precision motion. However, their limitations are also evident: elastic deformation of the flexspline results in relatively poor impact resistance, making them less suitable for sudden heavy loads.

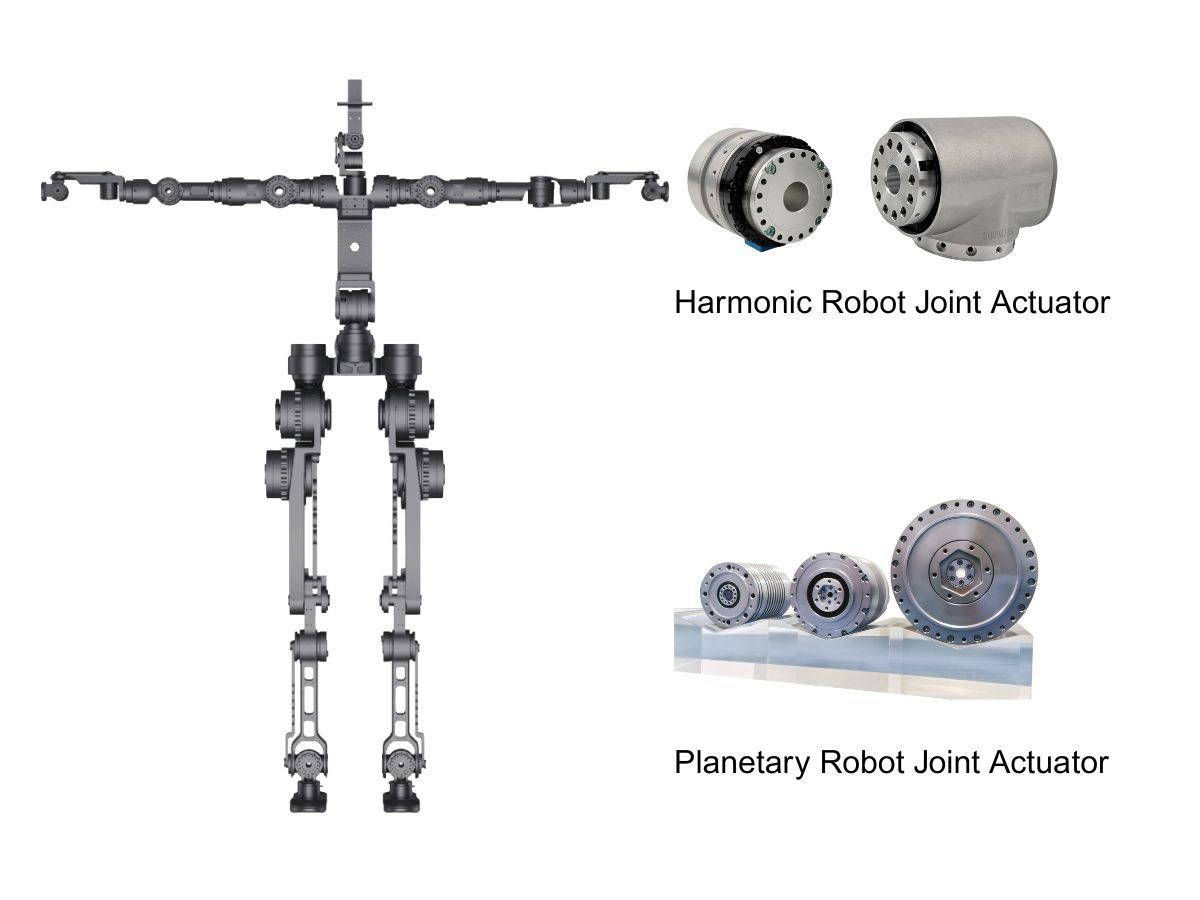

Lower-Limb Joints: Stability and Load-Bearing as the Priority

Lower-limb joints are responsible for stable load bearing, making planetary actuators the more balanced choice. Planetary actuators rely on rigid meshing among the sun gear and planetary gears, achieving transmission efficiencies as high as 95–97%. Their impact resistance far exceeds that of harmonic modules, allowing them to easily withstand ground reaction forces during bipedal locomotion as well as the robot’s own weight.

Notably, even a single-stage planetary reduction solution can support loads of hundreds of kilograms, fully meeting the requirements of walking and payload carrying.

Equally important, planetary actuators offer outstanding cost-effectiveness. The cost of a single-stage unit is typically only a few hundred RMB, significantly lower than that of harmonic actuators. With a mature domestic supply chain, planetary actuators are well suited for large-scale mass production. Moreover, lower-limb joints generally have more installation space and do not require extreme compactness, which naturally accommodates the relatively larger size of planetary actuators at equivalent reduction ratios.

Exceptions: Differentiated Paths Driven by Product Positioning

There are, however, notable exceptions. The differentiated strategies adopted by Unitree and UBTECH are primarily driven by their distinct product positioning.

Unitree focuses on small, lightweight robots. Its G1 robot uses a self-developed planetary actuator that delivers instantaneous torque of up to 140 N·m within a compact form factor, making it suitable for highly dynamic scenarios such as running and jumping. This approach sacrifices some positioning accuracy in exchange for stronger impact resistance and cost advantages.

In contrast, UBTECH’s Walker S1 adopts harmonic actuators across all joints, targeting industrial-grade high-precision applications. With peak torque reaching 250 N·m, structural reinforcement is used to compensate for the inherent impact resistance limitations of harmonic drives, enabling deployment in scenarios with extremely high requirements for operational accuracy.

Both approaches demonstrate that, based on their core application scenarios, these companies have deliberately abandoned a generic configuration in favor of highly customized actuator solutions.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand