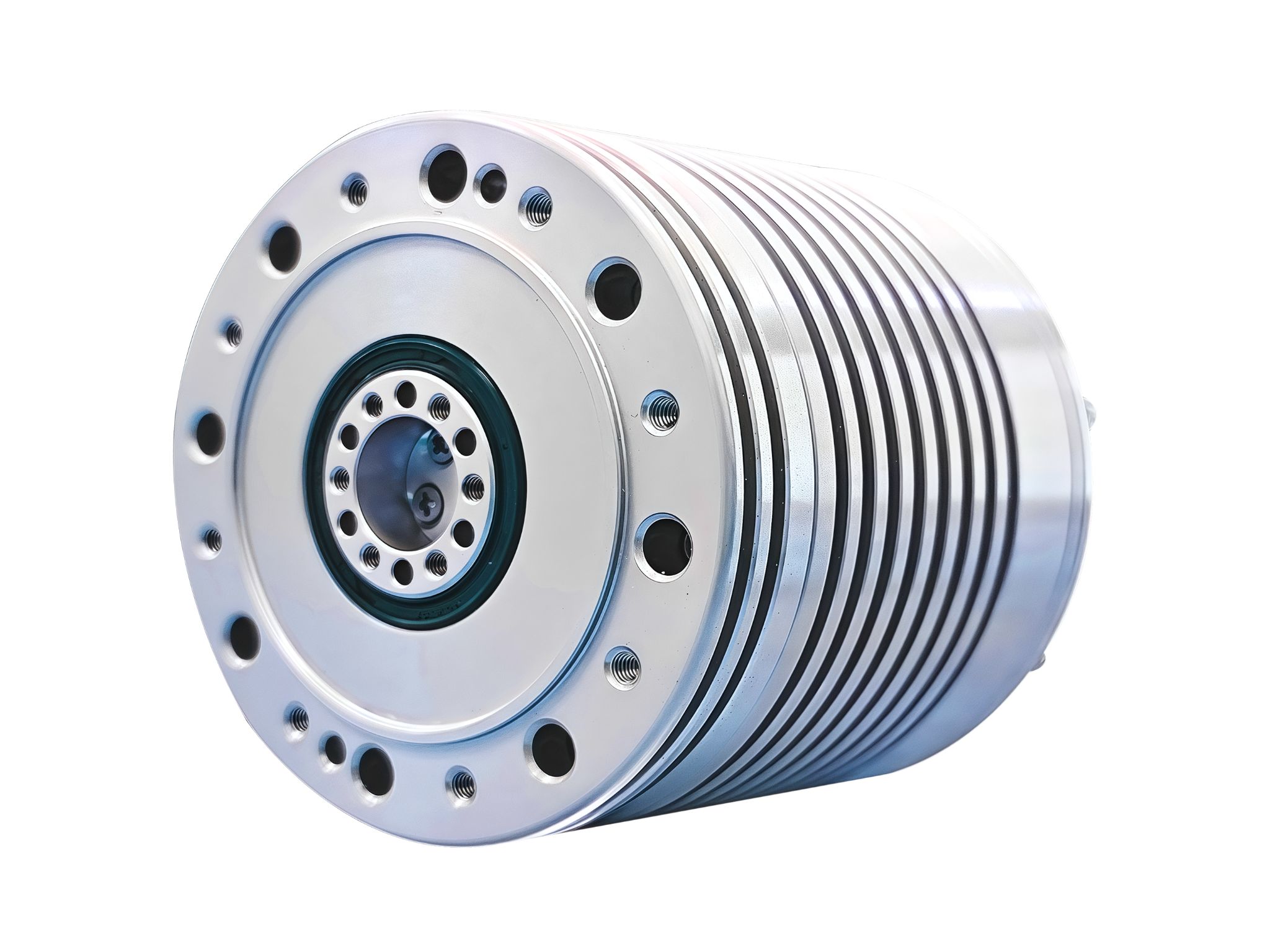

High Speed Impact Resistance Compact Lightweight Planetary Joint Module

● Introduction

With core advantages such as high-speed performance, impact resistance, and compact lightweight design, the Standard Planetary Joint Module has become the preferred solution for high-load drives in humanoid robots, specialized robots, logistics AGVs, and industrial automation, driving advancements in robotic performance and broader application scenarios.

Application

● High Torque Density and Power Performance

Multi-stage planetary reduction structure: Through multi-stage gear combination, torque density can reach above 20N·m/kg, suitable for high-load driving requirements of robotic hip joints, legs and other parts.

Peak torque output: Delivers greater peak torque output, meeting instantaneous power demands in dynamic motion scenarios.

● Impact Resistance and High Reliability

Advantages of planetary gear transmission: Gear meshing disperses impact force, can withstand harsh working conditions such as emergency stops and high-frequency load changes, suitable for high-dynamic scenarios like bipedal robot walking and jumping.

Mass production controllability: Planetary reducer solution has mature technology with high mass production consistency and reliability, suitable for large-scale applications.

● Compact Structure and Lightweight Design

High integration: Nested design of planetary reducer, frameless motor, encoder and other components reduces volume by 30% compared to traditional solutions.

Lightweight materials: Uses high-strength alloys and compact layout to meet humanoid robots' stringent requirements for lightweight and high energy efficiency.

● High Precision and Low Energy Consumption

Low cogging torque and dual encoder closed-loop: Reduces torque ripple, combined with dual absolute encoders (motor end + output end) achieves ±0.05° repeat positioning accuracy.

Transmission efficiency optimization: Planetary reducer transmission efficiency reaches above 80%.

● Multi-axis Coordinated Control

Supports CAN bus protocol to meet multi-degree-of-freedom coordinated motion requirements of robots.

● Economy and Maintenance Convenience

Maintenance-free design: Stable planetary reducer structure requires no regular lubrication, reducing long-term usage costs.

Modular interfaces: Standardized design facilitates quick replacement and upgrades, shortening robot development cycles.

Features

● Power Unit

Frameless torque motor: Provides compact power source, suitable for high dynamic response requirements.

Two-stage planetary reducer: Optimizes space through nested gear structure, improves torque transmission efficiency.

● Sensing and Control

Dual absolute encoders (motor end + output end): Supports full closed-loop control, improves positioning accuracy.

Friction brake: Ensures emergency stop safety and zero-speed starting stability.

● Communication Module

Supports CAN bus protocol, compatible with multi-axis coordinated control.

Specification

Sheet 1