HONPINE Establishes Ultra-Fine Grain Harmonic Reducer R&D and Production Center, Aiming to Surpass Japan's Harmonic Drive in Precision

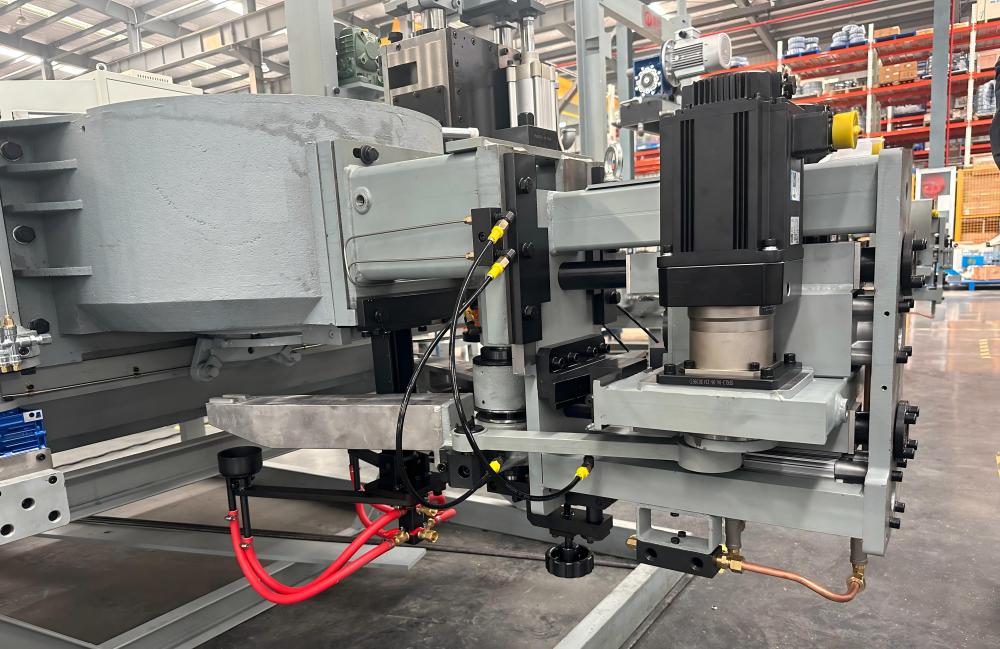

To meet the growing demand for higher precision in harmonic reducers from customers in CNC, humanoid robots, medical equipment, and other application fields, HONPINE has established an ultra-fine grain R&D and production center. The center plans to adopt ultra-fine grain production technology to enhance the precision and rigidity of harmonic reducers.

Why Adopt Ultra-Fine Grain Harmonic Reducers Production Technology?

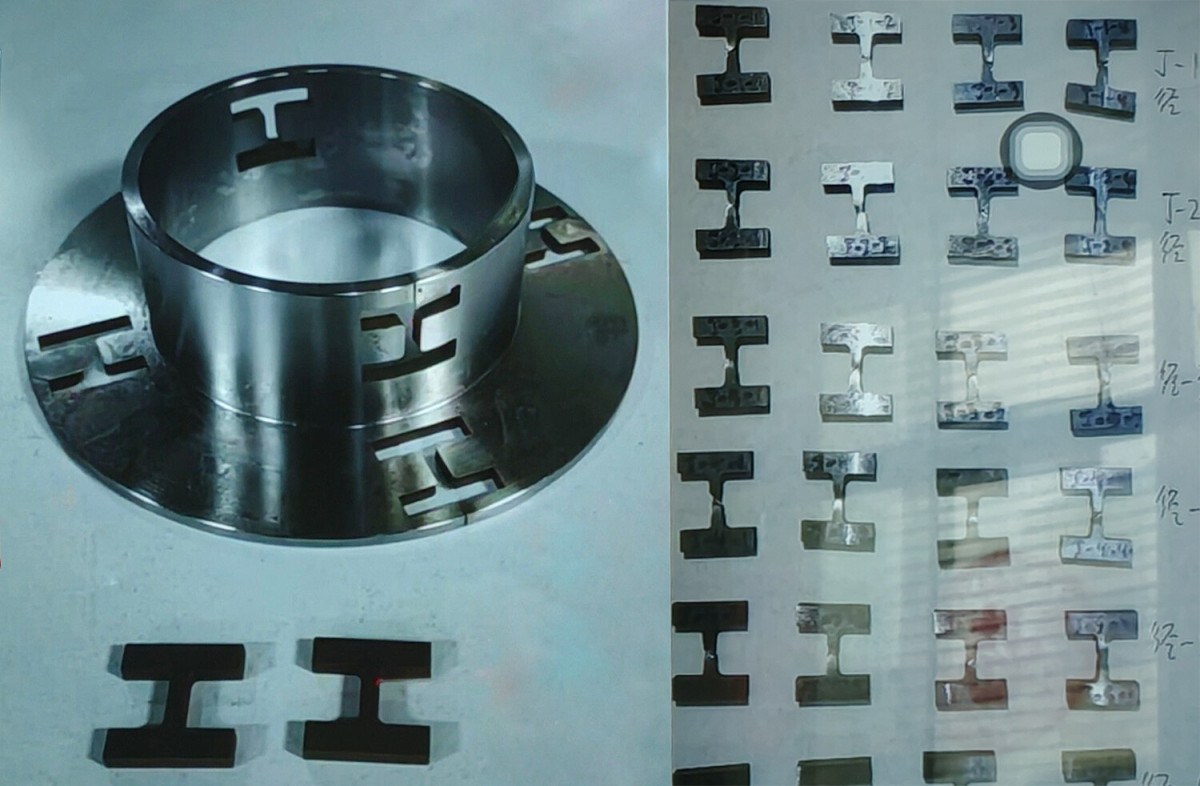

1,Through ultra-fine grain heat treatment, an average grain size of ≤7μm can be achieved, reaching an ultra-fine grain level of 11–11.5 grade with superior organizational uniformity.

2,Material properties include a tensile strength of 1,500 MPa, yield strength of 1,425 MPa, yield ratio of 0.95, and strength-ductility balance >15,000.

The table below shows the tensile test results after heat treatment:

Ultra-Fine Grain Harmonic Reducers Manufacturing Process

Ultra-fine grain heat treatment process: Raw material → Hot forming → Pre-treatment → Heat treatment → Surface treatment

What Performance Can Be Achieved with Ultra-Fine Grain Technology?

Gear accuracy grade < DIN4, roundness < 0.003, dimensional error < 0.01

HONPINE’s Harmonic Reducers R&D Focus

HONPINE’s R&D direction is driven by customer and market demands. In 2025, the primary focus is addressing the need for improved precision and rigidity in harmonic reducers. In addition to the ultra-fine grain R&D project, the new ultra-fine planetary reducer represents a major technological breakthrough (completely resolving the trade-off between precision and rigidity in harmonic reducers).

Contact us to learn more about HONPINE’s latest technologies.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand