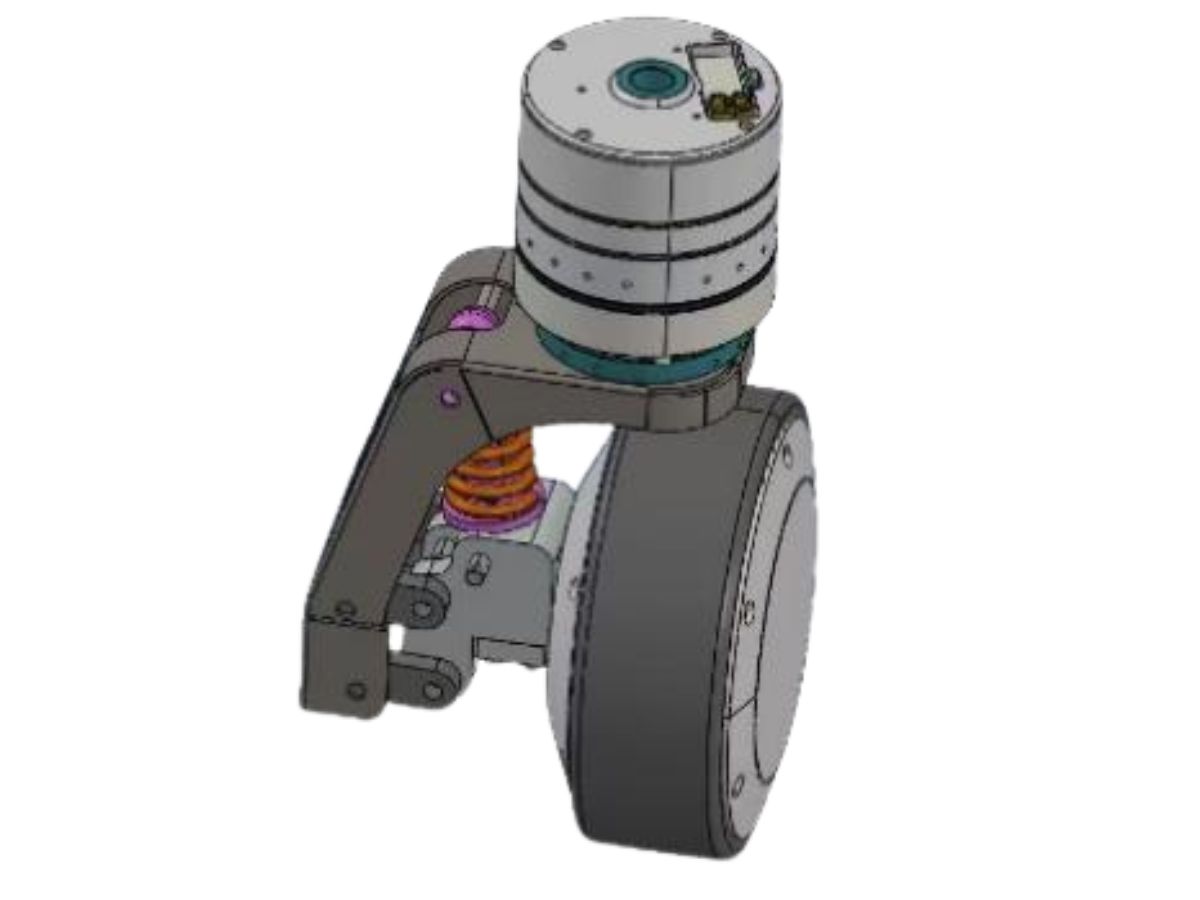

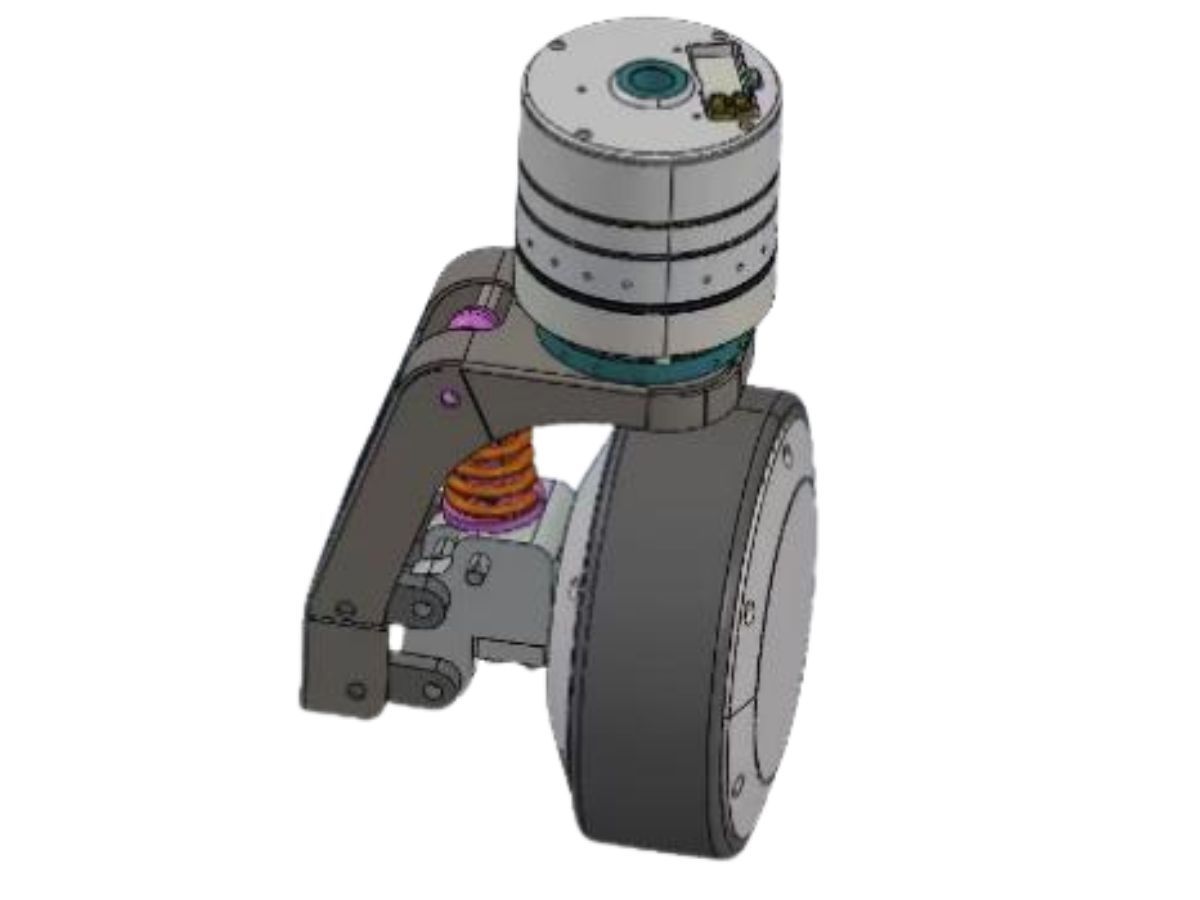

Harmonic rotary actuators are an ideal drive solution for high-end AGV systems

AGVs can adopt various drive solutions, such as planetary gear reducers or reducers with specialized mechanical structures. However, for AMRs and precision-handling AGVs that demand extremely high motion smoothness and positioning accuracy, harmonic rotary actuators are one of the ideal drive solutions. Their high positioning accuracy and smooth operation enable AGVs to achieve precise path tracking and docking, while their compact and lightweight design frees up valuable space inside the AGV chassis for integrating additional sensors or batteries.

Application of Harmonic Rotary Actuators in AGV Drive Wheels

Harmonic rotary actuators can be used to control the lifting mechanisms of stacker cranes or the traveling mechanisms of shuttle vehicles, enabling micron-level precise positioning to ensure efficient and safe cargo storage and retrieval. On high-speed sorting lines, they are also used to drive critical diverter mechanisms, ensuring that parcels are accurately routed to designated exits within milliseconds.

Why Harmonic Rotary Actuators Are Superior to Planetary Gear Reducers

Near-Zero Backlash

Based on harmonic drive technology, harmonic rotary actuators feature near-zero backlash, eliminating transmission gaps and reverse dead zones in wheel hub motors, thus enabling extremely precise steering angle control.

Ultra-High Reduction Ratio

The ultra-high reduction ratio of harmonic drives allows wheel hub motors to achieve micron-level control resolution, delivering significantly higher control precision with the same motor.

Highly Compact and Lightweight Design

The compact design of harmonic rotary actuators reduces axial length, improving the structural efficiency of hub motors, enabling thinner chassis designs and a lower center of gravity.

For AMRs and precision-handling AGVs that pursue ultimate motion smoothness, sub-millimeter positioning accuracy, and high system integration, adopting integrated harmonic rotary actuators as hub motor solutions not only offers inherent advantages in control precision and dynamic response, but also provides greater design freedom for vehicle lightweighting and intelligent integration. As such, harmonic drive–based rotary actuators represent a key development direction for high-end AGV drive systems.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand