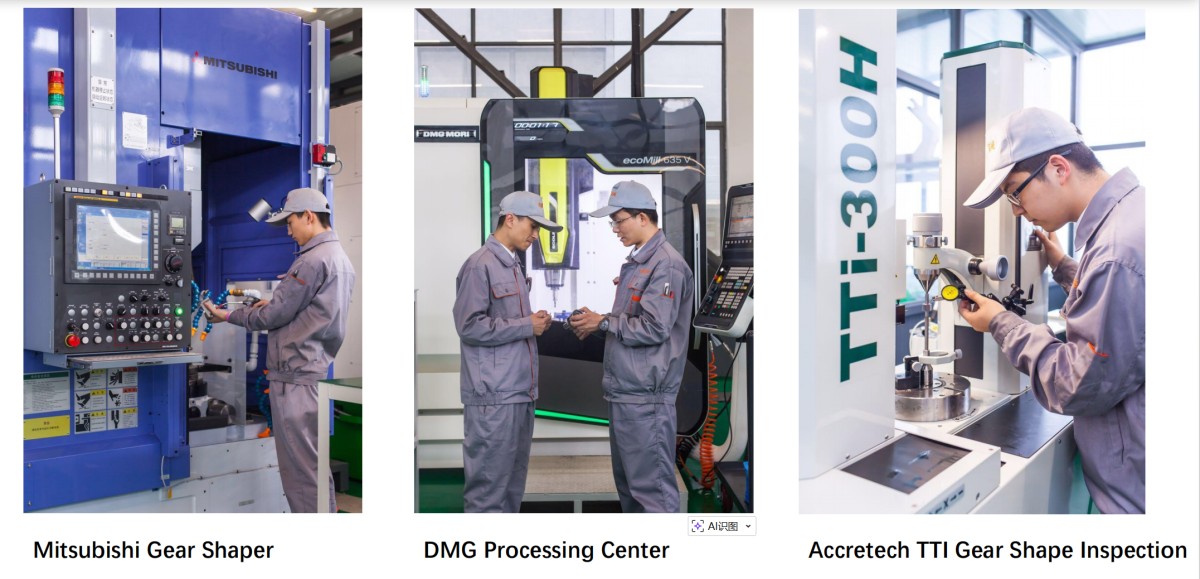

How Does HONPINE Ensure the Quality of High Precision Planetary Gearboxes as a Manufacturer?

As a precision planetary gearbox manufacturer for high-end machinery, HONPINE adopts high-precision machining technologies during the production process. At the same time, we implement strict quality inspection procedures to ensure the quality of every planetary gearbox. This article introduces the quality inspection process that HONPINE high-precision planetary gearboxes must go through.

Basic Appearance and Assembly Compliance Inspection

(Initial inspection, manual + basic tools)

Appearance inspection:

The housing and end covers must be free from dents, scratches, and paint peeling; flange surfaces and shaft ends must be free from burrs and corrosion; nameplate parameters (model, gear ratio, rated torque, backlash grade) must be consistent with the order.

Assembly dimension inspection:

Calipers, micrometers, and height gauges are used to measure shaft extension length, flange mounting hole position accuracy, locating pin hole precision, and mounting surface flatness; shaft end radial runout ≤ 0.01 mm (precision grade) / ≤ 0.03 mm (industrial grade).

Manual rotation inspection:

Under no-load conditions, manually rotate the input shaft. The output shaft should rotate smoothly without sticking or abnormal noise (any abnormal noise or jamming results in direct rejection). Rotational resistance should be uniform without sudden changes.

Sealing and lubrication inspection:

No oil seepage or leakage from the housing; lubrication oil filling quantity meets process requirements (oil level reaches the specified mark); seals (oil seals / sealing rings) are properly installed without misalignment.

Core Precision Inspection

(100% inspection, high-precision dedicated equipment)

Precision is the core indicator of planetary gearboxes. All products must undergo full inspection with data recorded, which is also the key basis for distinguishing product grades. All inspections are conducted under no-load conditions at normal temperature and pressure.

1. Backlash inspection (core precision indicator, most critical)

Inspection purpose: To verify the idle error during reverse rotation of the gearbox and match the specified grade (such as P0 ≤ 1 arcmin, P1 ≤ 3 arcmin, P2 ≤ 5 arcmin, P3 ≤ 10 arcmin).

Inspection equipment: High-precision backlash testing instrument (equipped with torque sensor and angular encoder, resolution 0.01 arcmin), indexing head + dial indicator.

2. Transmission error inspection (mandatory for precision grade, optional for industrial grade)

Inspection purpose: To verify the deviation between the actual output angle and the theoretical output angle at a fixed transmission ratio, reflecting the precision stability of continuous transmission (more representative of actual working conditions than backlash).

Inspection equipment: Gear transmission error comprehensive testing instrument (equipped with high-speed angular encoder and servo drive, resolution 0.001 arcmin).

3. No-load rotational accuracy inspection

Inspection purpose: To verify rotational accuracy under no-load conditions and eliminate assembly errors of the shaft system and bearings.

Inspection equipment: Roundness tester / runout tester + dial indicator, laser alignment instrument.

Inspection items: Radial runout and axial play of input shaft / output shaft; face runout of the housing mounting surface.

Performance Inspection

(100% inspection, load test bench, under load conditions)

Based on precision compliance, the transmission performance, efficiency, and torque matching of the gearbox under load are verified, simulating light / medium load conditions in actual operation. Direct loading to rated or peak torque is prohibited to avoid overload damage to new products.

1. No-load loss and no-load torque inspection

Inspection purpose: To verify rotational resistance under no-load conditions, reflecting friction losses of bearings and gear meshing. Excessive losses may lead to excessive temperature rise and reduced efficiency.

2. Transmission efficiency inspection

Inspection purpose: To verify the energy transmission efficiency of the gearbox, which is one of the core performance indicators (typical planetary gearbox efficiency is 95%–98%; efficiency slightly decreases as the gear ratio increases).

3. Temperature rise characteristic inspection (with light load)

Inspection purpose: To verify temperature rise under no-load / light-load conditions and eliminate abnormal temperature rise caused by excessive bearing preload or overly small gear meshing clearance.

4. Torque transmission characteristic inspection

Inspection purpose: To verify the torque transmission capability of the gearbox and eliminate torque loss caused by poor gear meshing or loose keyway fit.

Reliability Inspection

(Sampling inspection, according to batch / order requirements, load aging tests)

Light-load running-in test

Method: Input shaft at constant speed (500–1000 rpm), output shaft loaded with 0.2 times the rated torque, continuous operation for 2–4 hours (4 hours for precision grade, 2 hours for industrial grade). During operation, there should be no abnormal noise or oil leakage; housing temperature rise should be stable without sudden increase; after shutdown, manual rotation should remain smooth.

Short-time peak torque test

The output shaft is loaded with 1.5 times the rated peak torque, and the input shaft rotates at low speed (10–20 rpm) for 5–10 minutes. There should be no gear tooth breakage, shaft deformation, or housing cracking; after shutdown, backlash is re-measured, and the variation should be ≤ 0.5 arcmin (precision grade).

Vibration and noise inspection

Equipment: Vibration tester (acceleration sensors), sound level meter (accuracy ±1 dB).

During light-load running-in, acceleration sensors are attached at the housing bearing positions and meshing areas to measure vibration acceleration (≤ 0.5 g for precision grade); noise is measured at a distance of 1 m from the gearbox, ≤ 60 dB (A-weighted, precision grade) / ≤ 70 dB (industrial grade). No abnormal vibration peaks or sharp noises (such as metal scraping or impact sounds) are allowed.

If you need to purchase high-quality, high-end planetary gearboxes, add HONPINE to your supplier list now.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand