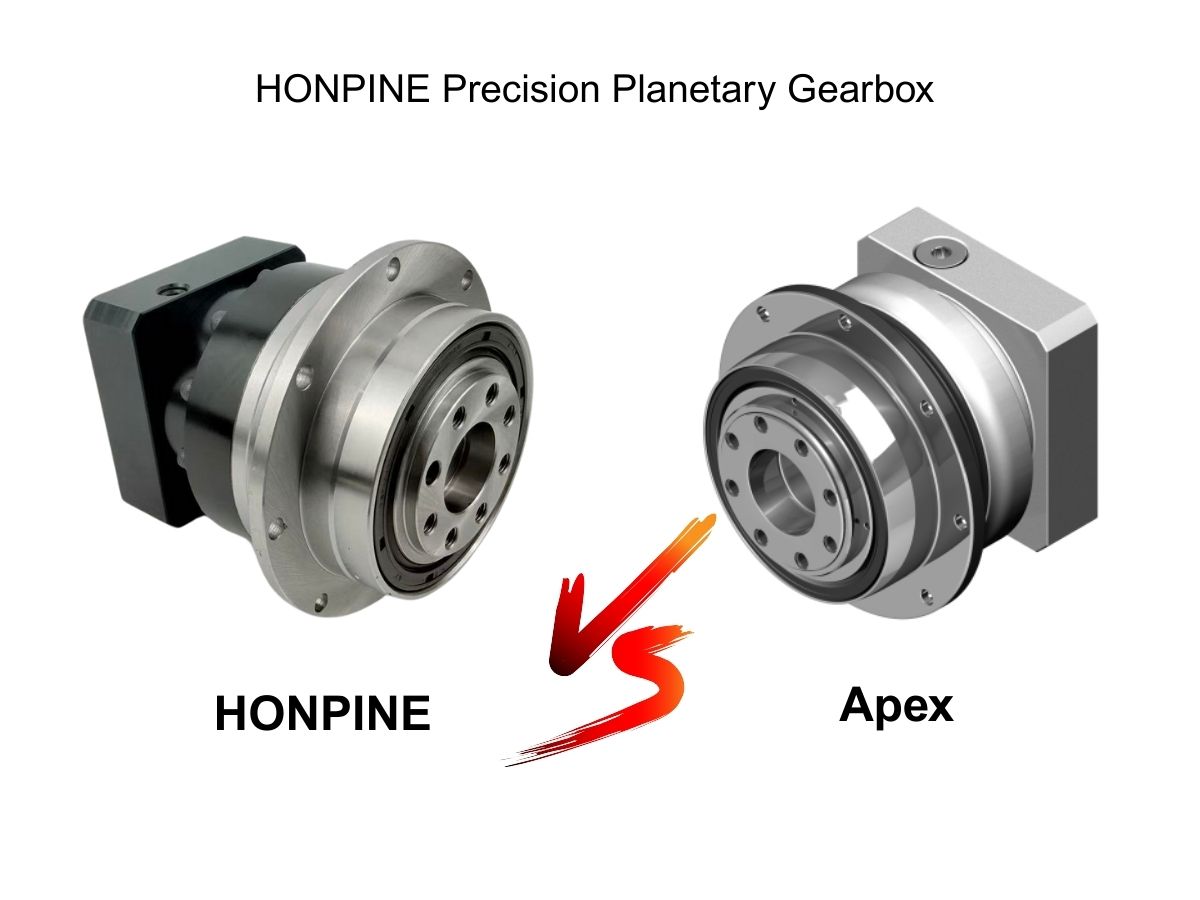

HONPINE Anti-Backlash Planetary Gearbox: Redefining CNC Machine Tool Boundaries with Ultra-High Bending Stiffness

Among gearbox performance metrics, bending stiffness (often overlooked compared to precision and torsional stiffness) directly determines the limits of CNC machine tool machining. HONPINE’s anti-backlash planetary gearbox is redefining these limits with its ultra-high parameters.

What is Bending Stiffness?

Bending stiffness (also called moment stiffness or tilting stiffness) simply measures a gearbox’s ability to resist "bending over." Its unit is Nm/arcmin – a higher value means less tilting under the same external force, i.e., a "stiffer backbone."

Example: 1 Nm/arcmin means applying 1 Nm of torque tilts the output shaft by 1 arcmin (1 arcmin ≈ 0.0167°).

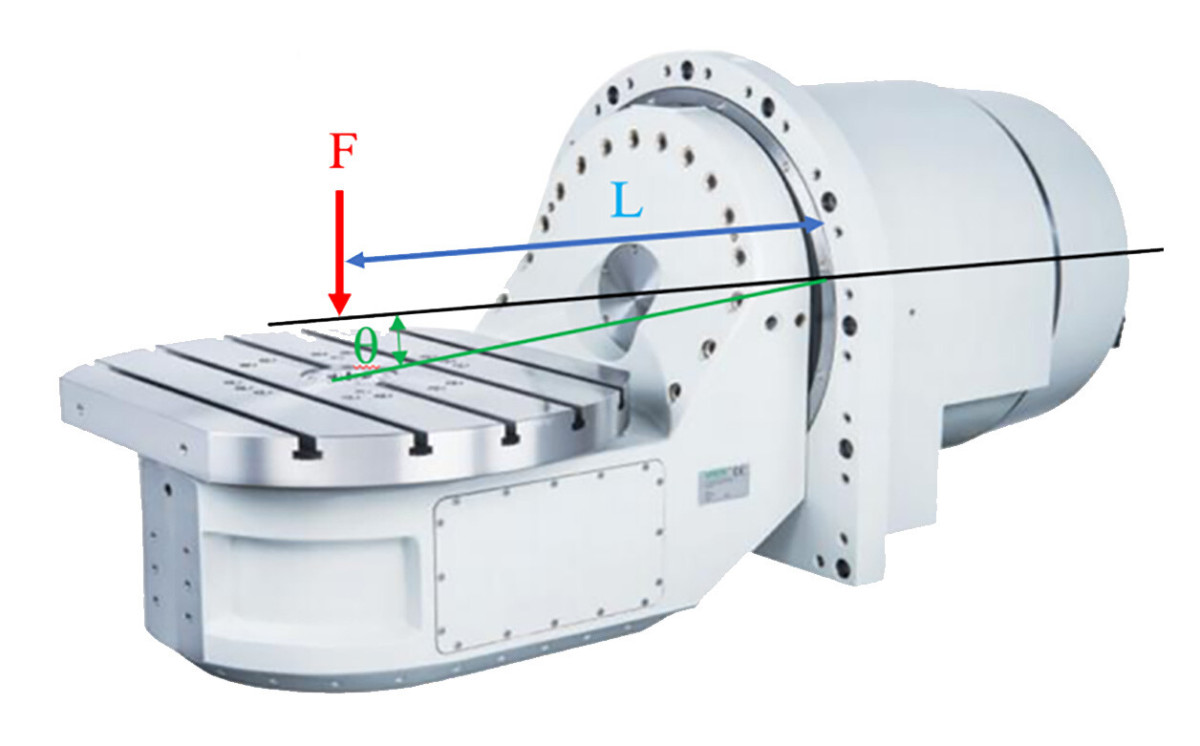

How is Bending Stiffness Tested?

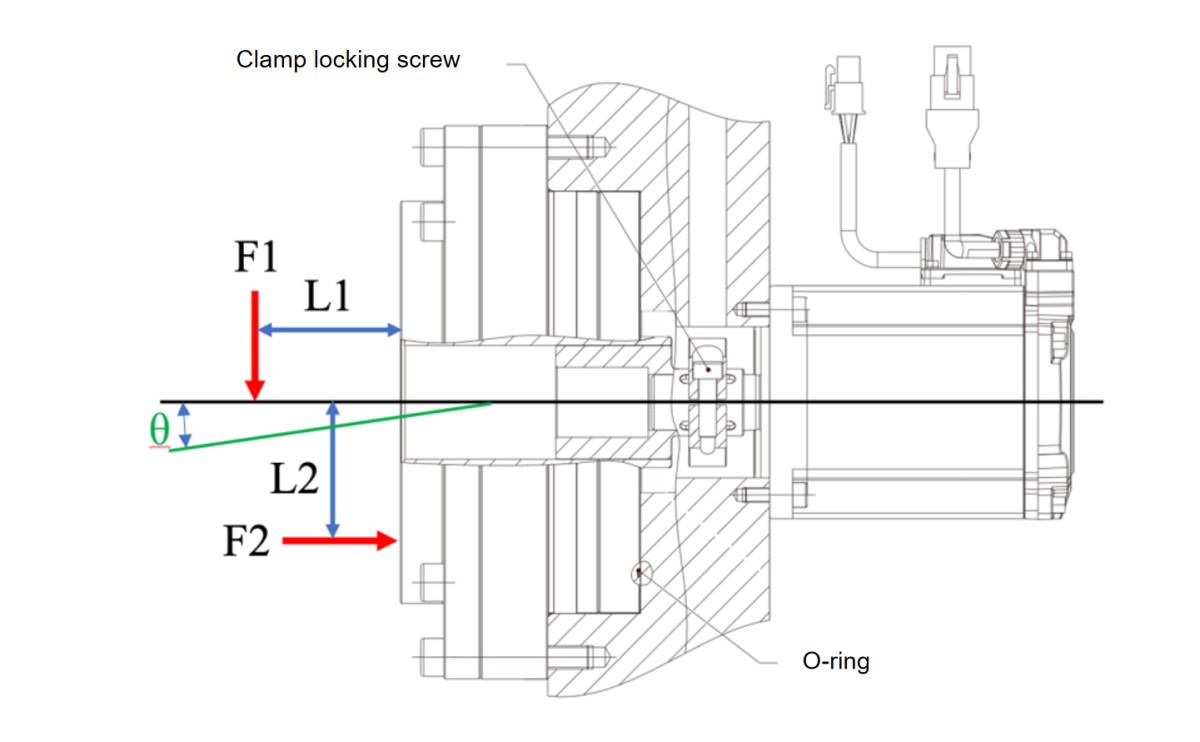

The measurement principle is intuitive (see diagram below):

Apply forces F₁ and F₂ at the output end, with lever arms L₁ and L₂.

Calculate bending moments: W₁ = F₁ × L₁, W₂ = F₂ × L₂.

Measure the resulting angular deflection θ of the output shaft.

Calculate bending stiffness: Nm/arcmin = W / θ.

Higher values = greater stiffness = less tilting under load.

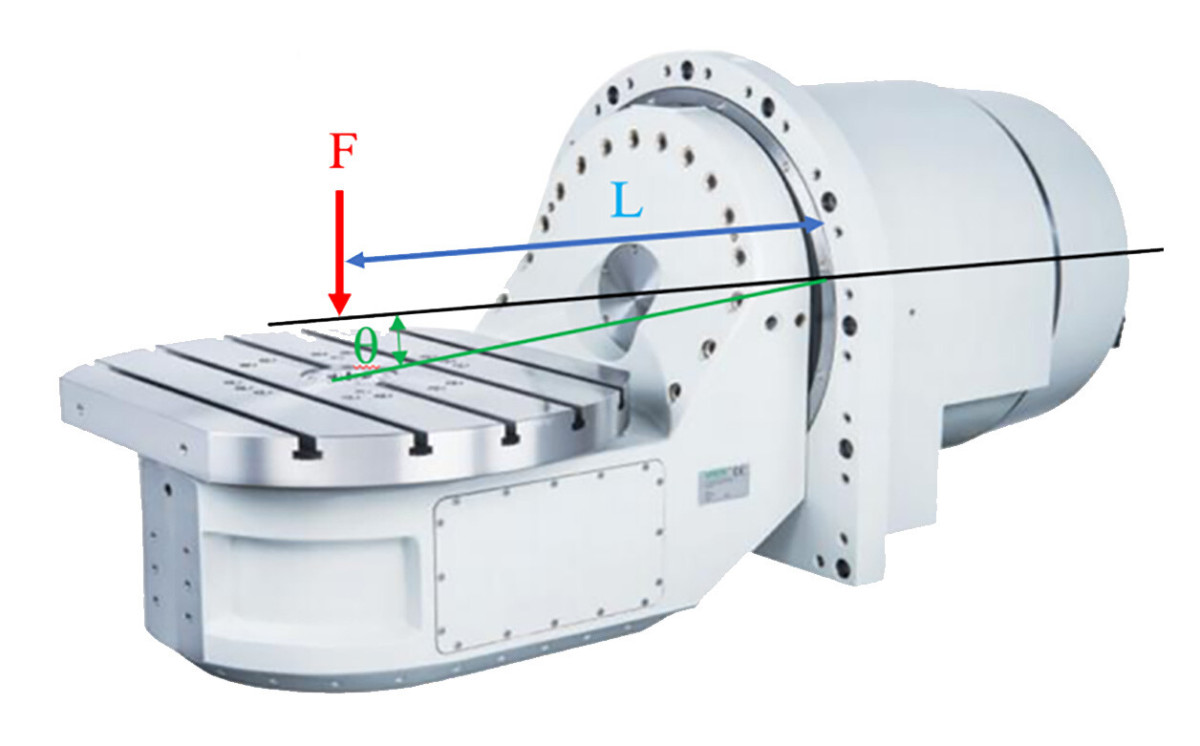

Why Does Bending Stiffness Matter in CNC Applications?

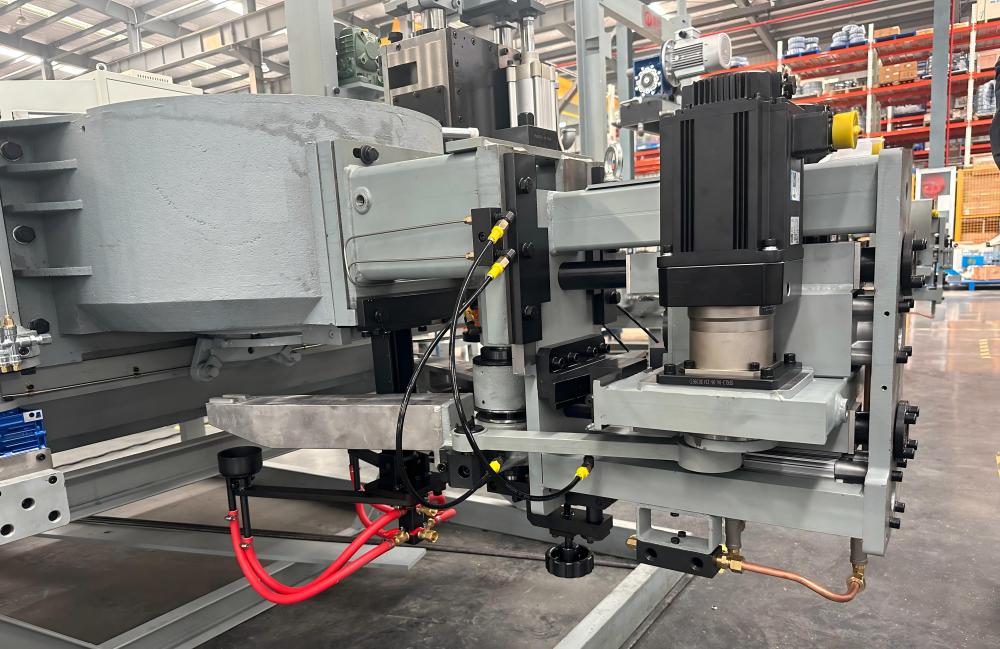

Consider a CNC 5-axis rotary table (diagram below): A radial force F acts at distance L from the gearbox, causing angular deflection θ on the A-axis.Scenario:

210mm table, A-axis under 100kg radial load (F), lever arm L = 240mm. Performance comparison:

Japanese Harmonic Drive® (Model 40)

Stiffness: 264.6 Nm/arcmin

Deflection: θ = (F × g × L) / 264.6 = 0.89 arcmin

Displacement at F: 0.062 mm

Japanese RV-Style Cycloid® (Model RV-40E)

Stiffness: 931 Nm/arcmin

Deflection: θ = (F × g × L) / 931 = 0.25 arcmin

Displacement: 0.0174 mm

German Anti-Backlash Design (Model 056)

Stiffness: 1,170 Nm/arcmin

Deflection: θ = (F × g × L) / 1,170 = 0.20 arcmin

Displacement: 0.014 mm

HONPINE Anti-Backlash Planetary Gearbox (Model H3K-40T)

Stiffness: 2,250 Nm/arcmin

Deflection: θ = (F × g × L) / 2,250 = 0.105 arcmin

Displacement: 0.007 mm

Summary: Performance Comparison Under Identical Loads

The HONPINE H3K-40T Anti-Backlash Planetary Gearbox achieves decisive superiority.

Consequences of Insufficient Bending Stiffness in CNC Machining

Plummeting Accuracy: Tool-workpiece misalignment → dimensional/shape errors.

Increased Vibration: Lower natural frequency → CNC chatter, poor surface finish.

Reduced Efficiency: Forced lower CNC feed rates → longer machining times.

Tool Damage: Vibration accelerates wear/brittle fracture → higher costs.

How HONPINE Achieves Ultra-High Stiffness

Integrated 3-row "YRT-type" turntable bearings

Needle roller races machined directly onto gearbox components (monolithic design)

Simultaneously delivers:

Extreme bending stiffness

High moment load capacity

High axial thrust resistance

Minimal runout (face/radial) → maximum stability

This design enables the H3K series anti-backlash planetary gearbox to provide unparalleled support in compact spaces, effortlessly handling heavy loads and severe radial moments in high-precision CNC applications.

Bending stiffness dictates CNC machine tool precision, efficiency, and longevity. HONPINE anti-backlash planetary gearboxes prove that 2,250 Nm/arcmin is no longer theoretical – it’s now a reality for demanding CNC systems.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

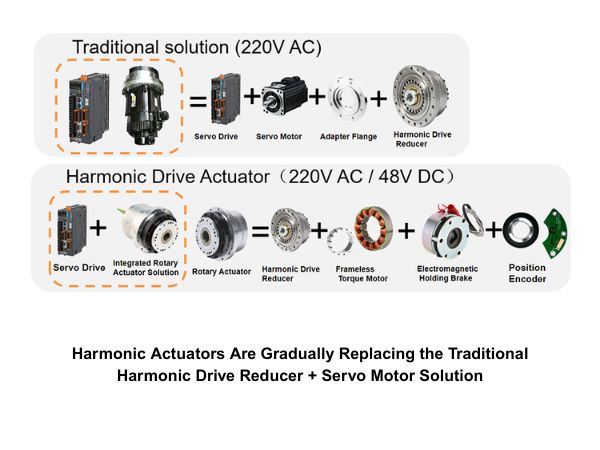

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand